194x Filetype XLSX File size 0.04 MB Source: ventionblobs.s3.amazonaws.com

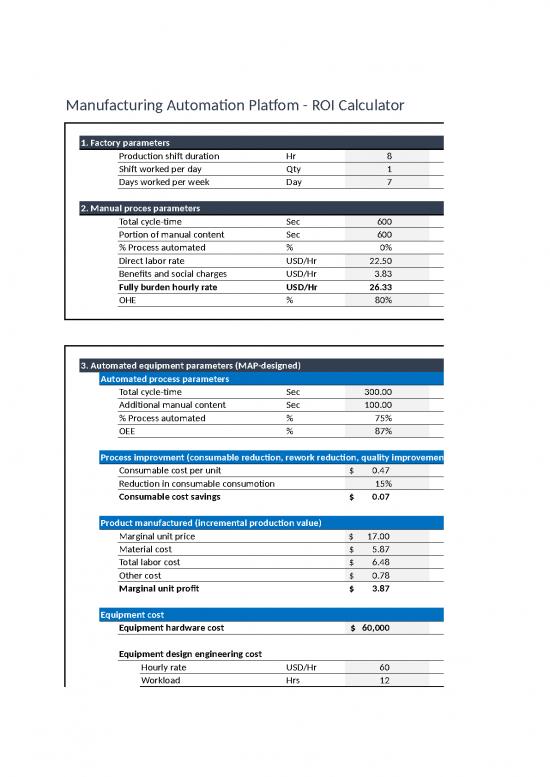

Manufacturing Automation Platfom - ROI Calculator

1. Factory parameters

Production shift duration Hr 8

Shift worked per day Qty 1

Days worked per week Day 7

2. Manual proces parameters

Total cycle-time Sec 600

Portion of manual content Sec 600

% Process automated % 0%

Direct labor rate USD/Hr 22.50

Benefits and social charges USD/Hr 3.83

Fully burden hourly rate USD/Hr 26.33

OHE % 80%

3. Automated equipment parameters (MAP-designed)

Automated process parameters

Total cycle-time Sec 300.00

Additional manual content Sec 100.00

% Process automated % 75%

OEE % 87%

Process improvment (consumable reduction, rework reduction, quality improvement)

Consumable cost per unit $ 0.47

Reduction in consumable consumotion 15%

Consumable cost savings $ 0.07

Product manufactured (incremental production value)

Marginal unit price $ 17.00

Material cost $ 5.87

Total labor cost $ 6.48

Other cost $ 0.78

Marginal unit profit $ 3.87

Equipment cost

Equipment hardware cost $ 60,000

Equipment design engineering cost

Hourly rate USD/Hr 60

Workload Hrs 12

Total $ 720

Equipment software programming cost

Hourly rate USD/Hr 60

Workload Hrs 20

Total $ 1,200

Equipment assembly cost

Hourly rate USD/Hr 60

Workload Hrs 40

Total $ 2,400

Equipment site commissioning cost

Hourly rate USD/Hr 60

Workload Hrs 40

Total $ 2,400

Equipment project management and administrative cost

Hourly rate USD/Hr 60

Workload Hrs 2

Total $ 120

Other equipment cost USD $ 10,000

Total equipment cost $ 76,840

4. Automated equipment parameters (Traditional approach)

Automated process parameters

Total cycle-time Sec 275.00

Additional manual content Sec 100.00

% Process automated % 73%

OEE % 92%

Process improvment (consumable reduction, rework reduction, quality improvement)

Consumable cost per unit $ 0.47

Reduction in consumable consumotion 15%

Consumable cost savings $ 0.07

Product manufactured (incremental production value)

Marginal unit price Sec $ 17.00

Material cost $ 5.87

Total labor cost $ 6.48

Other cost $ 0.78

Marginal unit profit $ 3.87

Equipment cost

Equipment hardware cost $ 85,000

Equipment design engineering cost

Hourly rate USD/Hr 120

Workload Hrs 120

Total $ 14,400

Equipment software programming cost

Hourly rate USD/Hr 200

Workload Hrs 20

Total $ 4,000

Equipment assembly cost

Hourly rate USD/Hr 95

Workload Hrs 80

Total $ 7,600

Equipment site commissioning cost

Hourly rate USD/Hr 150

Workload Hrs 40

Total $ 6,000

Equipment project management and administrative cost

Hourly rate USD/Hr 60

Workload Hrs 39

Total $ 2,340

Other equipment cost USD $ 10,000

Total equipment cost $ 129,340

4. ROI Summary

Auto Equip (MAP-designed) vs. Manual process

Daily production with auto equip. Units 84

Daily production with manual process Units 38

Current process cost USD per unit $ 5.48

Automated process cost USD per unit $ 0.91

Process cost savings USD per unit $ 4.57

Consumable savings USD per unit $ 0.07

Incremental volume USD per unit $ 3.87

Units to breakeven Units 11,415

Time to breakeven Months 4.5

Auto Equip (Traditional approach) vs. Manual process

Daily production with auto equip. Units 96

Daily production with manual process Units 38

Current process cost USD per unit $ 5.48

Automated process cost USD per unit $ 0.91

Process cost savings USD per unit $ 4.57

Consumable savings USD per unit $ 0.07

Incremental volume profit USD per unit $ 3.87

Units to breakeven Units 18,561

Time to breakeven Months 6.3

Auto Equip (Designed in MAP) vs. Auto Equip (Traditional approach)

Equipment cost difference $ 52,500 41%

Units to breakeven difference Units 7,146 38%

Time to breakeven difference Months 1.8 29%

MAP Traditional approach

Equipment cost comparison (USD) Manufactured units to breakeven (#)

Cost $ 76,840 $ 129,340

$129,340 18,561

Unit to br 11,415 18,561

Payback 4.5 6.3

$76,840 11,415

MAP Traditional approach MAP Traditional approach

no reviews yet

Please Login to review.