234x Filetype XLSX File size 1.17 MB Source: www.sonaca.com

Sheet 1: QRS 00.00 rev 3

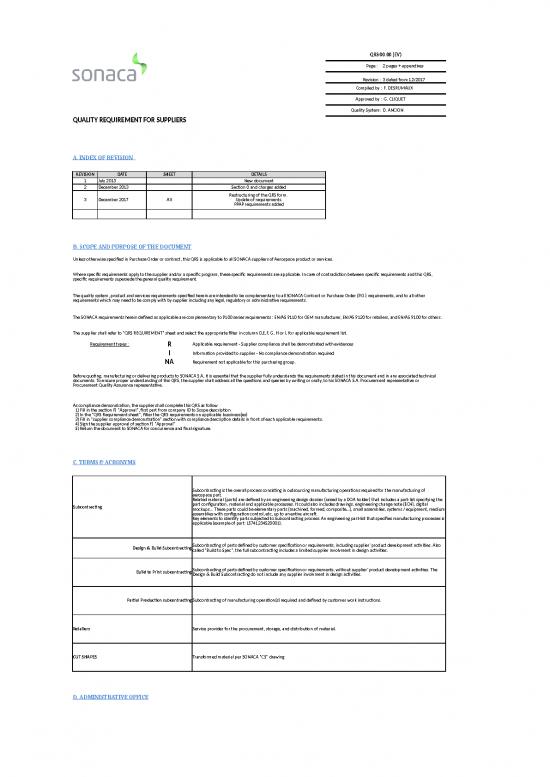

| QRS 00.00 (EV) | |||||||||||

| Page : | 2 pages + appendixes | ||||||||||

| Revision : | 3 dated from 12/2017 | ||||||||||

| Compiled by : | F. DESRUMAUX | ||||||||||

| Approved by : | G. CLIQUET | ||||||||||

| Quality System: | D. ANCION | ||||||||||

| QUALITY REQUIREMENT FOR SUPPLIERS | |||||||||||

| A. INDEX OF REVISION | |||||||||||

| REVISION | DATE | SHEET | DETAILS | ||||||||

| 1 | July 2013 | New document | |||||||||

| 2 | December 2013 | Section 0 and charges added | |||||||||

| 3 | December 2017 | All | Restructuring of the QRS form. Update of requirements. PPAP requirements added |

||||||||

| B. SCOPE AND PURPOSE OF THE DOCUMENT | |||||||||||

| Unless otherwise specified in Purchase Order or contract, this QRS is applicable to all SONACA suppliers of Aerospace product or services. |

|||||||||||

| Where specific requirements apply to the supplier and/or a specific program, these specific requirements are applicable. In case of contradiction between specific requirements and this QRS, specific requirements supersede the general quality requirement. | |||||||||||

| The quality system, product and services requirements specified herein are intended to be complementary to all SONACA Contract or Purchase Order (P.O.) requirements, and to all other requirements which may need to be comply with by supplier including any legal, regulatory or administrative requirements. | |||||||||||

| The SONACA requirements herein defined as applicable are complementary to 9100 series requirements : EN/AS 9110 for OEM manufacturer, EN/AS 9120 for retailers, and EN/AS 9100 for others. | |||||||||||

| The supplier shall refer to "QRS REQUIREMENT" sheet and select the appropriate filter in column D,E,F, G, H or I, for applicable requirement list. | |||||||||||

| Requirement types : | R | Applicable requirement - Supplier compliance shall be demonstrated with evidences | |||||||||

| I | Information provided to supplier - No compliance demonstration required | ||||||||||

| NA | Requirement not applicable for this purchasing group. | ||||||||||

| Before quoting, manufacturing or delivering products to SONACA S.A, it is essential that the supplier fully understands the requirements stated in this document and in any associated technical documents. To ensure proper understanding of this QRS, the supplier shall address all the questions and queries by writing or orally, to his SONACA S.A. Procurement representative or Procurement Quality Assurance representative. | |||||||||||

| As compliance demonstration, the supplier shall complete this QRS as follow 1) Fill in the section F) "Approval", first part from company ID to Scope description 2) In the "QRS Requirement sheet", filter the QRS requirements on applicable bussiness(es) 3) Fill in "supplier compliance demonstration" section with compliance description details in front of each applicable requirements. 4) Sign the supplier approval of section F) "Approval" 5) Return the document to SONACA for concurrence and final signature. |

|||||||||||

| C. TERMS & ACRONYMS | |||||||||||

| Subcontracting | Subcontracting is the overall process consisting in outsourcing manufacturing operations required for the manufacturing of aerospace part. Related material (parts) are defined by an engineering design dossier (raised by a DOA holder) that includes a part-list specifying the part configuration, material and applicable processes. It could also includes drawings, engineering change note (ECN), digital mockups... These parts could be elementary parts (machined, formed, composite…), small assemblies, systems / equipment, medium assemblies with configuration control, etc, up to an entire aircraft. Key elements to identify parts subjected to Subcontracting process: An engineering part-list that specifies manufacturing processes is applicable (example of part: L5741234520001). |

||||||||||

| Design & Build Subcontracting | Subcontracting of parts defined by customer specification or requirements, including supplier' product development activities. Also called "Build to Spec", the full subcontracting includes a limited supplier involvment in design activities. | ||||||||||

| Build to Print subcontracting | Subcontracting of parts defined by customer specification or requirements, without supplier' product development activities. The Design & Build Subcontracting do not include any supplier involvment in design activities. | ||||||||||

| Partial Production subcontracting | Subcontracting of manufacturing operation(s) required and defined by customer work instructions. | ||||||||||

| Retailers | Service provider for the procurement, storage, and distribution of material. | ||||||||||

| CUT SHAPES | Transformed material per SONACA "CS" drawing | ||||||||||

| D. ADMINISTRATIVE OFFICE | |||||||||||

| All correspondence related to this manual shall be addressed to: | SONACA Route nationale 5 6041 Gosselies (Belgium) |

||||||||||

| InspectionSous-traitance@sonaca.com | |||||||||||

| E. DEVIATION & CHARGES | |||||||||||

| Any deviation regarding applicable quality or logistic requirements, contract and/or PO mandatory requirements, logistic protocol or condition of supply shall be the subject of a claim addressed to the Supplier. Except otherwise specified by the contract, these claims shall be subjected to the following charges : | |||||||||||

| Item | Comments | Charges(1) (2) set by SONACA | Additionnal condition(s) | ||||||||

| Quality or Logistic claim subsequent to supplier default or undeclared non conformities on delivered product | This amount covers mainly product inspection, administrative tasks & claim documentation, segregation of non-conformance items, and supplier corrective action follow-up. | 500 € / claim | |||||||||

| Additional inventory checks | The rate includes charges for incoming inspection service disruption | 80 € / hour | |||||||||

| Product incoming inspection performed by SONACA for known recurrent non conformities (claim occurrence ≥ 2) | These charges include costs for incoming inspection service disruption | 80 € / hour | |||||||||

| SONACA WIP - work in progress - scraps due to supplier product undeclared non conformity | This amount covers mainly administrative costs (production planning disruption, manufacturing order issuing, cancelation and reissuing, administrative quality management of the scrap). | 250 € / scraped production order + Costs related to the work performed by the Buyer with regard to the scrapped product | |||||||||

| Costs claimed by final customer related to supplier non-conformities and admin costs related to the customer claim management. | Extra costs example: return / transportation costs of NC products, replacement parts manufacturing and delivery, special repairing parts, etc. | Direct cascade of costs | |||||||||

| (1) Without prejudice to the right of the Buyer to claim higher damages based on evidence of higher actual damage | |||||||||||

| (2) These charges could be cumulated where several Item criteria are met. | |||||||||||

| F. APPROVALS | |||||||||||

| COMPANY NAME / Location | |||||||||||

| Design & Build Subcontracting | RETAILERS | ||||||||||

| Build to Print subcontracting | CUT SHAPES | ||||||||||

| Partial Production subcontracting | OEM & EQUIPEMENT | ||||||||||

| SCOPE OF APPLICATION : | |||||||||||

| Short description with contract reference, bussiness agreement, program or work package description | |||||||||||

| For SUPPLIER : | Position | NAME | Date | Signature | |||||||

| Prepared | |||||||||||

| Checked | |||||||||||

| Approved | |||||||||||

| For SONACA : | Position | NAME | Date | Signature | |||||||

| Prepared | Supplier Quality Enginneer | ||||||||||

| Checked | Commodity Senior Buyer | ||||||||||

| Approved | SQD Manager | ||||||||||

| REQUIREMENT APPLICABILITY | OPR OPERATIONAL REQUIREMENTS |

SUPPLIER COMPLIANCE DEMONSTRATION | Date of review : | |||||||||||

| Applicability OPR id |

Design & Build Subcontracting Refer to definition |

Build to Print subcontracting Part to customer drawing set (2D/3D/Part List/ECN) |

Partial Production subcontracting Production operation(s) per SONACA Work Instructions |

RETAILERS E.g : Raw material, products, fasteners |

CUT SHAPES Transformed material per SONACA "CS" drawing |

OEM & EQUIPEMENT | Company : | |||||||

| 9100 series referenced chapter | Normative document or tool reference |

Compliance | Not applicable justification or Agreed deviation detailed |

Means of compliance reference / location | ||||||||||

| 1.0.0 | SCOPE | 1.0.0.01 | R | R | R | NA | R | NA | The supplier Quality Management System applied for the SONACA ordered product or service shall be certified as compliant to EN9100 requirements by a Certification Body accredited by IAQG ICOP Scheme. Only certifications registered in OASIS database shall be valid. Corresponding 9100 series chapter and subsections are applicable.. |

|||||

| 1.0.0 | SCOPE | 1.0.0.02 | NA | NA | NA | NA | NA | R | The supplier Quality Management System applied for the SONACA ordered product or service shall be certified as compliant to EN9110 requirements by a Certification Body accredited by IAQG ICOP Scheme. Only certifications registered in OASIS database shall be valid. Corresponding 9100 series chapter and subsections are applicable.. |

|||||

| 1.0.0 | SCOPE | 1.0.0.03 | NA | NA | NA | NA | R | NA | The supplier Quality Management System applied for the SONACA ordered product or service shall be certified as compliant to EN9120 requirements by a Certification Body accredited by IAQG ICOP Scheme. Only certifications registered in OASIS database shall be valid. Corresponding 9100 series chapter and subsections are applicable.. |

|||||

| 1.0.0 | SCOPE | 1.0.0.04 | R | R | R | R | R | R | The Supplier shall inform SONACA in case of suspension or withdrawal of its QMS certification. | |||||

| 1.0.0 | SCOPE | 1.0.0.05 | R | R | R | R | R | R | The Supplier shall notify to SONACA any significant change to its Quality Management System (e.g. change of scope). | |||||

| 1.0.0 | SCOPE | 1.0.0.06 | R | R | R | R | R | R | The Supplier shall grant SONACA access to the area of OASIS database containing detailed certification related information and provide any information about the content of the OASIS report upon SONACA's request. | |||||

| 2.0.0 | Normative Reference | 2.0.0.01 | R | R | R | R | R | R | Corresponding 9100 series chapter and subsections are applicable.. |

|||||

| 2.0.0 | Normative Reference | 2.0.0.02 | I | I | I | I | I | I | REACH regulation | The European Union REACH regulation (Registration, Evaluation, Authorization and Restriction of Chemicals) (Regulation (EC) No. 1907/2006) became effective June 1, 2007. REACH legislation puts all responsibility on industry, not government, to demonstrate the safety of chemical substances and to manage the risks that chemicals may pose to human health and to the environment.Identification of Substances of Very High Concern (SVHC) as identified in the ECHA Candidate List (see https://www.echa.europa.eu). | ||||

| 2.0.0 | Normative Reference | 2.0.0.03 | R | R | R | R | R | R | REACH regulation | Under application of the REACH regulation, the supplier shall 1) identify every chemical product procured or used for the execution of the SONACA order, |

||||

| 2.0.0 | Normative Reference | 2.0.0.03 | R | R | R | R | R | R | REACH regulation | Under application of the REACH regulation, the supplier shall 2) Collect the Safety Data Sheet and check the REACH records of referenced substances (CAS number) |

||||

| 2.0.0 | Normative Reference | 2.0.0.03 | R | R | R | R | R | R | REACH regulation | Under application of the REACH regulation, the supplier shall 3) Declare the usage of substances classified as SVHC, listed in the Autorisation list (REACH annex XIV). |

||||

| 2.0.0 | Normative Reference | 2.0.0.10 | R | R | R | R | R | R | ISO 14001 | SONACA has commited to an environmental management system certificated ISO 14001. Suppliers shall be ISO 140001 certified or in process. | ||||

| 3.0.0 | Terms and Definitions | 3.0.0.01 | R | R | R | R | R | R | Corresponding 9100 series chapter and subsections are applicable.. |

|||||

| 4.0.0 | Quality Management System | 4.0.0.01 | R | R | R | R | R | R | Corresponding 9100 series chapter and subsections are applicable.. |

|||||

| 4.1.0 | General Requirement | 4.1.0.05 | R | R | NA | NA | NA | R | EASA Part21 subpart G | Where required by SONACA, the Supplier shall have a Production Organisation Approval (POA) in compliance with EASA standard i.e. EC 1702/2003 Part 21, and/or FAA 14 CFR Part 21, and/or equivalent. The supplier shall inform SONACA of any airworthiness directive affecting their product. |

||||

| 4.1.0 | General Requirement | 4.1.0.10 | R | R | R | R | R | R | The supplier shall provide to SONACA upon demand copies of : Supplier Quality Manual latest revision, certificates / approvals such as Quality Standards Certificates, approvals delivered by Prime manufacturers, manufacturing & inspection processes certificates granted by other primes or NADCAP, copy of the last Quality System audit report performed by an external organisation, any questionnaire or assessmenent required by SONACA. | |||||

| 4.2.1 | General | 4.2.1.05 | R | R | R | R | R | R | General specifications such as EN, AMS, MS, MIL, RG Aero, NFL…and product specification are not provided to Supplier for copyright reasons, but shall be provisioned or ordered by the Supplier at their latest version. | |||||

| 4.2.3 | Control of Documents | 4.2.3.05 | R | R | R | R | R | R | Any document communicated by the purchaser to the supplier shall be considered as applicable unless applicability is refuted by the supplier within 30 days following its reception. Moreover, the supplier shall acknowledge the reception of the document. | |||||

| 4.2.3 | Control of Documents | 4.2.3.10 | R | R | R | R | R | R | The Supplier shall set up a system guaranteeing that any modification in applicable specifications or in drawing or specification sent by the Purchaser will be implemented. | |||||

| 4.2.3 | Control of Documents | 4.2.3.15 | R | R | R | R | R | R | DSI/STND | The Supplier shall use all the documentation at the required revision, or the latest revision where omitted. The supplier can find SONACA standards in the SONACA TFT website. | ||||

| 4.2.3 | Control of Documents | 4.2.3.15 | I | I | I | I | I | I | DSI/STND | Access rights onto the SONACA TFT website is submitted to specials rules, including having an effective NDA - Non Disclosure Agreement - signed between SONACA and the supplier, or integrated in the contract. Any question related to the system and access rights should be adressed to the SONACA buyer. | ||||

| 4.2.4 | Control of Record | 4.2.4.05 | R | R | R | R | R | R | EN9130 | Records shall be kept by the supplier according to management principles requested by EN9130 except retention duration: 10 years or duration defined by EN9130 whichever is the longest. Moreover, special controlled parts, class 1 parts, software and serialized parts related records shall be kept for 50 years. | ||||

| 4.2.4 | Control of Record | 4.2.4.10 | R | R | R | NA | R | NA | EN9130 | Archives and Quality records defined per EN9130 remain the property of SONACA S.A. | ||||

| 4.2.4 | Control of Record | 4.2.4.15 | R | R | R | NA | R | NA | Every SONACA record kept by the supplier shall be clearly identify as SONACA property and stored separately. | |||||

| 4.2.4 | Control of Record | 4.2.4.20 | R | R | R | R | R | R | In case of termination of contract between SONACA S.A. and the Supplier, the archives shall remain accessible to SONACA representatives or transferred, with prior authorization, to SONACA S.A. | |||||

| 4.2.4 | Control of records | 4.2.4.25 | R | R | R | R | R | R | Records shall be available at any time and supplied upon request. | |||||

| 5.0.0 | MANAGEMENT RESPONSIBILITY | 5.0.0.01 | R | R | R | R | R | R | Corresponding 9100 series chapter and subsections are applicable.. |

|||||

| 5.1.0 | Management Commitments | 5.1.0.05 | R | R | R | R | R | R | The supplier shall fulfil the specific requirements from the product and the drawing in addition to local and international regulations for environment, health and safety. | |||||

| 5.5.0 | Responsibility, Authority and Communication | 5.5.0.05 | R | R | R | R | R | R | SONACA, its representatives or mandated representatives, its customers or government representatives shall have the right to conduct audits or any inspection survey at any point of the manufacturing cycle within the Supplier's facilities, which may include visits to Subtiers and/or vendors facilities. | |||||

| 5.5.0 | Responsibility, Authority and Communication | 5.5.0.10 | R | R | R | R | R | R | The Supplier shall provide SONACA representative on request throughout the contract life cycle with a fully equipped office (including state-of-the-art IT connections), which is close to the manufacturing shop. | |||||

| 6.0.0 | Resource Management | 6.0.0.01 | R | R | R | R | R | R | Corresponding 9100 series chapter and subsections are applicable.. |

|||||

| 6.0.0 | Resource Management | 6.0.0.05 | R | R | R | R | R | R | The Supplier shall determine and provide the resources needed to meet customer requirements. It includes human resources, machines, production and inspection equipment such as CMM, IT software & hardware, toolings and any other necessary resources. | |||||

| 6.2.0 | Human Resources | 6.2.0.05 | R | R | R | R | R | R | The Supplier shall identify knowledge, skills & competencies necessary for the order execution, including but not restricted to special techniques, and ensure that human resources are carried out by personnal accordingly skilled. | |||||

| 6.2.0 | Human Resources | 6.2.0.10 | R | R | R | R | R | R | Critical resources or resources being concerned by technique certification shall be identified, available and adequate in number to ensure the workload. Back up shall be available. | |||||

| 6.2.0 | Human Resources | 6.2.0.15 | R | R | R | R | R | R | The Supplier shall nominate, authorise and register Certification Signatories within their Quality Management System. The signatories shall be detailed, including signature samples, within the Quality Assurance Plan. | |||||

| 6.3.0 | Infrastructure | 6.3.0.10 | R | R | R | NA | R | R | PDS-DQ 13.1.14 | The Supplier shall request and obtain effective access rights to login onto the purchaser’s system for nonconforming product management. | ||||

| 6.3.0 | Infrastructure | 6.3.0.15 | R | R | R | NA | R | R | PDS-DQ 9.5.2 | The Supplier shall request and obtain effective access rights to login onto the purchaser’s system for First Article Inspection Reports collection | ||||

| 6.3.0 | Infrastructure | 6.3.0.20 | R | R | R | NA | R | NA | The supplier shall be able to open and read the Catia© models provided by SONACA and called out as applicable definition. Where a file conversion is ordered or performed by the supplier, the integrity of the converted files shall be verified and validated. |

|||||

| 6.3.0 | Infrastructure | 6.3.0.25 | I | I | I | NA | I | NA | Frequently known conversion issues are affecting a loss or change of models FTA - Functional Tolerancing & Annotation. These FTA are necessary for the determination of requirements related to the product. |

|||||

| 7.0.0 | PRODUCT REALIZATION | 7.0.0.01 | R | R | R | R | R | R | Corresponding 9100 series chapter and subsections are applicable.. |

|||||

| 7.1.0 | Planning of Product Realization | 7.1.0.05 | NA | NA | R | NA | NA | NA | Product realization shall be carried out according to SONACA provided Work Instructions | |||||

| 7.1.2 | Risk Management | 7.1.2.05 | R | R | R | R | R | R | The supplier shall perform a risks analysis and keep a risk register up to date focused on activities initiated in the framework of SONACA SA contract or P.O. | |||||

| 7.1.2 | Risk Management | 7.1.2.10 | R | R | R | R | R | R | Each risk identified shall be the subject of a criticality evaluation based on its probability of occurrence and its potential impacts (in case of occurrence) in terms of Quality, Cost and Delay. Critical risks shall be mitigated. | |||||

| 7.1.2 | Risk Management | 7.1.2.15 | R | R | R | R | R | R | Critical human resources or resources being concerned by technique certification shall be identified, managed and mitigated through the risk register. | |||||

| 7.1.4 | Control of Work Transfers | 7.1.4.05 | R | R | NA | R | R | R | IAQG SCMH Section 7.1 Work transfers |

Any Transfer of Work shall be managed by the supplier as a project according to guidance, requirement, phasing and gates provided by the IAQG SCMH chap. 7.1.1 . Each gate review, associated elements and "fillable form" of the SCMH shall be submitted to SONACA for approval before enterring into the next project phase. |

||||

| 7.1.4 | Control of Work Transfers | 7.1.4.10 | R | R | NA | R | R | R | IAQG SCMH Section 7.1 Work transfers |

SONACA reserves the rights to require or perform any complementary assessments of risk at supplier or candidate premises. SONACA reserves the rights to refuse passing a gate or to reject the whole Transfer of Work project at any time. |

||||

| 7.2.1 | Determination of Requirements Related to the Product | 7.2.1.05 | I | I | I | I | I | I | SONACA SA is responsible to define and specify product & services requirements the more precisely as possible in the purchase order, contract, or work instruction. | |||||

| 7.2.1 | Determination of Requirements Related to the Product | 7.2.1.15 | NA | R | R | NA | R | NA | PS 6.0003 | Where a SONACA Protection Code is specified on the design Part-List, the corresponding protection scheme is defined in PS. 6.0003 | ||||

| 7.2.2 | Review of Requirements Related to the Product | 7.2.2.05 | R | R | R | R | R | R | The supplier shall ensure that technical documents written exclusively in English are made understandable at point of use. If necessarry, documents can be translated under the supplier responsibility. In case of dispute, the original document shall always prevail. | |||||

| 7.2.2 | Review of Requirements Related to the Product | 7.2.2.10 | R | R | R | R | R | R | The Supplier shall carry out a feasibility/capability study about any modification of the contract and/or purchase order requested by the Purchaser. | |||||

| 7.2.2 | Review of Requirements Related to the Product | 7.2.2.15 | R | I | NA | I | I | I | Any additional change required by SONACA to product design requirements, such as product configuration or condition of supply, shall be specified on the Purchase Order or contract. These changes should be traceable through a manufacturing reserve suffix added by SONACA on the part number and detailed on the purchase order or contract. | |||||

| 7.2.2 | Review of Requirements Related to the Product | 7.2.2.20 | R | R | NA | NA | R | NA | For all manufacturing or inspection processes and test methods, the Supplier or their subcontractors shall comply with the Process Specifications / Process Instructions, as well as inspection processes and test methods standards listed in the drawing set. | |||||

| 7.2.2 | Review of Requirements Related to the Product | 7.2.2.25 | R | NA | NA | R | NA | R | The Supplier shall demonstrate the conformity of its organization to the Purchaser Quality requirements, including this QRS, by issuing a Quality Plan. The Quality Plan shall detail the means of compliance to requirements - including subtiers - reference the approved deviations, describe the allocated resources and the specific organization implemented. The Quality Plan and its further revisions shall be submitted to SONACA within 60 days after contract signature or PO approval.. | |||||

| 7.2.2 | Review of Requirements Related to the Product | 7.2.2.30 | R | R | R | R | R | R | The Supplier shall demonstrate the conformity of its organization to this QRS by filling in the QRS supplier compliance demonstration section. -----------> The compliance demonstration shall be submitted to SONACA before contract signature or PO approval. |

|||||

| 7.2.3 | Customer Communication | 7.2.3.05 | R | R | R | R | R | R | The supplier shall designate quality focal point(s) for SONACA and keep SONACA informed of their details. | |||||

| 7.2.3 | Customer Communication | 7.2.3.10 | R | R | R | R | R | R | Every written communication between SONACA and the SUPPLIER shall be preferably in English on in French. | |||||

| 7.2.3 | Customer Communication | 7.2.3.15 | R | R | R | R | R | R | Supplier’s focal points shall be able to communicate in French or English language. | |||||

| 7.2.3 | Customer Communication | 7.2.3.20 | I | I | I | I | I | I | Upon request, SONACA SA will provide the necessary assistance to the supplier in the understanding of requirements. | |||||

| 7.2.3 | Customer Communication | 7.2.3.25 | R | R | NA | NA | R | NA | I.Q.S.4.1.1 FC1864A |

Any predictable deviation to standards, raw material or processes requirement shall be submitted to and approved by SONACA prior to usage. RFA form - Request for Alternative - related to permanent deviation, or MC form - Manufacturing Change - related to temporary deviation shall be used by supllier. | ||||

| 7.2.3 | Customer Communication | 7.2.3.30 | R | R | NA | NA | R | NA | Any change in manufacturing source(s), process(es), inspection method(s), location of manufacture, tooling or materials shall be submitted to the Purchaser's Quality department before implementation. | |||||

| 7.3.0 | Design and Development | 7.3.0.05 | I | I | I | I | I | I | Design chapter of EN91xx standard is not applicable in this QRS. In case of design and / or development activities, specific requirements otherwise specified should be applicable in the frame of and accordingly to the aircraft program requirements. | |||||

| 7.4.1 | Purchasing process | 7.4.1.04 | R | R | R | R | R | R | Supplier shall ensure that the purchaser quality requirements are flown down and applied by its whole supply chain. | |||||

| 7.4.1 | Purchasing process | 7.4.1.05 | I | I | I | I | I | I | Batch processes as heat and surface treatments, especially when they are subcontracted, induce a high risk of product mix or identification error. The supplier shall mitigate this risk by taking appropriate measures to avoid part mixed up or confusion due to similarity. Such actions should be managed in the PFMEA. | |||||

| 7.4.1 | Purchasing process | 7.4.1.15 | R | R | R | R | R | NA | Liste des installations externes qualifiées | At the exception of special processes dully allocated to companies registered in the SONACA "Liste des installations externes qualifiées", a prior and written autorisation from SONACA shall be obtained by the Supplier before entering into partial or total subcontracting. SONACA's approval is granted through acceptance of the PPAP "Subtier Management" deliverable. | ||||

| 7.4.1 | Purchasing process | 7.4.1.25 | R | R | NA | NA | R | NA | RQF 90.03 | Only the suppliers qualified by the SONACA Quality department are authorized to buy aircraft manufacturing related items to be used during the manufacturing of subcontracted elements and in the framework of a definite contract. Moreover, the Supplier shall comply with the requirements specified in RQF 90.03. | ||||

| 7.4.1 | Purchasing process | 7.4.1.30 | R | R | NA | NA | R | NA | In case of the supplier wishes to use a Subcontractor (such as special processes) or Manufacturer (such as material, standards...) not yet qualified, a request for qualification shall be addressed to SONACA. SONACA reserves the right to approve or reject the applicant. Fees covering the qualification may be charged back to the Supplier. | |||||

| 7.4.1 | Purchasing process | 7.4.1.35 | R | R | R | R | R | R | Direct shipments - from supplier subtier to SONACA or - from supplier to SONACA customer shall be submitted to and approved by SONACA Quality Department prior delivery. |

|||||

| 7.4.1 | Purchasing process | 7.4.1.40 | R | R | NA | R | NA | R | Subtiers On-time & On-Quality performances shall be monitored by the Supplier. When required by SONACA, Supplier shall provide SONACA with the subtier list, performance indexes and corrective, preventive and risk-mitigation actions. |

|||||

| 7.4.1 | Purchasing process | 7.4.1.45 | NA | NA | NA | R | NA | NA | SONACA only accepts products from manufacturers indicated in the SONACA purchase order when precised. | |||||

| 7.4.2 | Purchasing Information | 7.4.2.05 | R | R | NA | R | R | R | The supplier shall identify SONACA S.A. as final customer in each released purchase order. | |||||

| 7.4.3 | Verification of Purchased Product | 7.4.3.05 | R | R | NA | R | R | R | Suppliers are accountable for product & process conformity of the products delivered by subtiers, even those designated by the Purchaser. Only Declaration of Conformity or Form 1 dully signed by Supplier autorized personal shall be accepted in delivery documentation. |

|||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.05 | R | R | R | NA | R | R | Supplier shall implement a policy and procedure for prevention, detection and removal of foreign object. | |||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F05 | R | R | R | NA | R | NA | EN9102 | The supplier shall perform a First Article Inspection (FAI) review for each ordered Part Number, according to the requirements set forth in EN/AS 9102 standard. Requirements considered for Part Numbers, Products and Characteristics accountabilities shall only be those required by SONACA in the contract or PO. |

||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F10 | R | R | R | NA | R | NA | EN9102 | Where the "as built" manufacturing required configuration differs from the "as designed" engineering configuration, the form 1 field 8 "Additionnal Changes" shall be completed. It applies to Mananufacturing Reserves, accomplished modifications, or approved Permit for Alternative or Manufacturing Changes (PFA / MC) |

||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F15 | R | R | R | NA | R | NA | PDS-DQ 9.5.2 | The supplier shall upload the FAI Report in the SONACA web portal before the first delivery of the concerned part. Refer to PDS-DQ 9.5.2 for guidance. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F20 | R | R | R | NA | R | NA | EN9102 | SONACA reserves the right to check the FAIR consistency and to reject it at anytime. Starting from the rejection notification date, the supplier shall update concerned FAIR within 5 working days for an administrative correction or prior to the next delivery if new production is necessary. |

||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F25 | I | I | I | NA | I | NA | FC3395-02 | Upon request, SONACA FAIR checklist is available to perform FAIR consistency check. This checklist can be used as guidance by the supplier for a FAIR self assessement prior to submission. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F30 | R | R | R | NA | R | NA | FC3395-02 | In case of reccurent FAIR rejection by SONACA, the supplier will be requested to fill in the FAIR self assessement checklist and to provide it as an attachment of each submitted FAIR up to relaxation of the demand. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F35 | I | I | I | NA | I | NA | EN9102 | At the exception of the "00" suffix code meaning [according to engineering], any additionnal suffix added to the engineering Part Number means that a manufacturing reserve applies to the required configuration. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F40 | R | R | R | NA | R | NA | EN9102 | The FAI Report shall be composed as a minimum of : the 3 EN/AS 9102 forms dully filled and signed, all certificates referenced in form 2, including Acceptance Test Procedure and Report, a ballooned drawing that locate every characteristics, a copy of the job card (production record), reports of CMM inspection, a copy of the SONACA purchase order item without prices including potential amendments, the supplier certificate of conformity. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F45 | R | R | R | NA | R | NA | EN9102 | CR (Conditionally Required) fields of EN/AS9102 forms shall be considered as required by SONACA | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F50 | R | R | R | NA | R | NA | EN9102 | Every raw material, standards and process specifications notes called out by design part list, drawing or digital mockup shall be included in FAIR Form 2. This includes alternative processes, free notes, and not applied processes. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F55 | R | R | R | NA | R | NA | EN9102 | All fields of FAIR forms 1, 2, and 3 shall be completed. Where a field is deemed as Not Applicable, "N/A" shall be reported rather than a blank field. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F60 | R | R | R | NA | R | NA | EN9102 | Where a product specification called out by the design (e.g. SMS) is defining characteristics or requirements applicable to the finished product, the specification shall be balloned and characteristic accountability shall be evaluated in FAIR form 3. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F65 | R | R | R | NA | R | NA | EN9102 | Every dimensional characteristic requirement (field 8) and measured results (field 9) In FAI form 3 shall be reported in the same unit of measurement as expressed on the drawing. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F70 | R | R | R | NA | R | NA | EN9102 | Required and actual weight shall be recorded on FAIR form 3. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.F75 | R | R | R | NA | R | NA | EN9102 | The supplier is accountable of the FAIR decision : FAIR Complete or Not Complete. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.P05 | I | I | NA | I | I | I | QRS 00.00 "APQP Phases" sheet | The SONACA purchasing & provisioning process is integrated throughout the product lifecycle into 5 APQP phases. Refer to "APQP PHASES" sheet of this QRS for details. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.P10 | I | I | NA | I | I | I | QRS 00.00 "PPAP REQUIREMENTS" sheet | For each [Product / Supplier] pair, SONACA quotes the product and the supplier risk to determine the PPAP LEVEL [Low / Medium / High]. The PPAP level is conditionning the amount of elligible PPAP deliverables. The PPAP level is communicated to the supplier within the RFQ. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.P15 | R | R | NA | R | R | R | EN9145 International Aerospace Quality Group Supply Chain Management Handbook |

The supplier shall demonstrate that the manufacturing and assembly processes can produce conforming product at the required rate. To support this demonstration, the supplier shall raise the required PPAP deliverables and submit them to SONACA at the required maturity throughout the APQP phases. Requirements and guidance shall be those of EN9145 and IAQG SCMH section 7.2 APQP, Phase 4, Element 4.09, except as follows. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.P20 | R | R | NA | R | R | R | QRS 00.00 "PPAP REQUIREMENTS" | According to the PPAP level established by SONACA, elligible PPAP deliverables are listed in the chart available on the "PPAP Requirement" sheet. The "Scope Matrix" form, defining the required deliverable applicable, shall be signed by the supplier and Sonaca before the PO review (Phase 2A). | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.P25 | R | NA | NA | NA | NA | R | QRS 00.00 "PPAP Requirement" | The supplier shall raise the required PPAP deliverables and submit them to SONACA, at the required maturity level, at least 5 working days before the planned or agreed date of each gate reviews. [Deliverables Maturity level / Gate Reviews] pairs are those listed in the "PPAP REQUIREMENTS" sheet, Gates Review for Design & Build Supplier APQP. |

||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.P30 | NA | R | NA | R | R | NA | QRS 00.00 "PPAP Requirement" | The supplier shall raise the required PPAP deliverables and submit them to SONACA, at the required maturity level, at least 5 working days before the planned or agreed date of each gate reviews. [Deliverables Maturity level / Gate Reviews] pairs are those listed in the "PPAP REQUIREMENTS" sheet, Gates Review for Build to Print Supplier APQP. |

||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.P35 | I | I | I | I | I | I | QRS 00.00 "PPAP Requirement" | PPAP deliverables forms are suggested by SONACA in the "PPAP REQUIREMENTS" sheet. The supplier own forms are nevertheless acceptable provided that this forms are already parts of the supplier QMS standards and consistent with the deliverable purpose. | ||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.P40 | R | R | NA | R | R | R | PPAP deliverables are submitted to verification and validation by SONACA. Verification are part of the gate reviews. Intermediate verifications could nevertheless be required by SONACA as part of IRM (Industrial Review Meeting) or PRM (Project Review Meeting). The supplier shall provide the necessary support for the SONACA verification and shall consider every comments : Deliverable update or justification. |

|||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.P45 | R | R | NA | R | R | R | The validation is achieved with the billateral signature of the PPAP submission certificate. Where required by SONACA customer, the supplier set of deliverables could be submitted by SONACA to customer and / or the PPAP submission certificate could also be sumitted to SONACA customer approval. | |||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.P50 | R | R | NA | R | R | R | QRS 00.00 "DELTA PPAP" sheet | All applicable PPAP deliverables shall by updated by the supplier each time the process or the product is changed. Resubmission is required by SONACA prior to change application. Rules defining the affected deliverables to update are detailed in the "Delta PPAP" sheet. |

||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.1.P55 | R | R | NA | R | R | R | For procured items or outsourced operations, the SONACA PPAP requirements shall be flow down to concerned subtiers. Subtiers deliverables shall be submitted as part of tier-1 deliverables. | |||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.10 | I | I | I | NA | I | NA | Some processes, such as surface treatment and paint application, may change the material thicknesses or dimensions. Unless overwise specified, drawings state finished parts dimensions. Adequate provision should then be taken to achieve the final part conformity. | |||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.15 | R | R | R | R | R | R | In addition to EN 9100 (or 9110/9120) requirements, work instructions shall include : · material and part/assembly traceability data |

|||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.17 | R | R | R | R | R | NA | PS6.8003 | In addition to EN 9100 (or 9110/9120) requirements, work instructions shall include : · Material conductivity/hardness measurements with minimum and Maximum limits required and measured, according to PS 6.8003 series requirements |

||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.19 | R | R | R | NA | R | NA | In addition to EN 9100 (or 9110/9120) requirements, work instructions shall include : · Special tools and their configuration status |

|||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.21 | R | R | R | NA | R | NA | In addition to EN 9100 (or 9110/9120) requirements, work instructions shall include : · FAI's to be performed |

|||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.23 | R | R | R | NA | R | NA | In addition to EN 9100 (or 9110/9120) requirements, work instructions shall include : · Specific points namely identified for certified personnel and special techniques |

|||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.25 | R | R | R | R | R | R | In addition to EN 9100 (or 9110/9120) requirements, work instructions shall include : · Mandatory interventions when requested by the Purchaser or government representatives. |

|||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.60 | R | R | NA | R | NA | NA | Initial revision of work instructions related to Special Controled, class 1 and serialized product shall be approved by SONACA before release to production. | |||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.70 | R | R | NA | R | R | R | For components or material subjected to Qualification, any modification in the manufacturer supply chain, production process and supply sources shall lead to a renewal of qualification and update of associated qualification reports. | |||||

| 7.5.1 | Control of Production and Service Provision | 7.5.1.72 | R | R | NA | NA | NA | NA | Any modification of work instructions related to Special Controled, class 1 and serialized product shall be approved by SONACA before release to production. | |||||

| 7.5.2 | Validation of Processes for Production and Service Production | 7.5.2.05 | R | R | R | NA | R | NA | SONACA Qualified Supplier List available on https website | Manufacturing and inspection processes submitted to qualification and requested by the design dossier, included the part-list or standard specification, shall be qualified by the Purchaser before any use in production. | ||||

| 7.5.2 | Validation of Processes for Production and Service Production | 7.5.2.07 | R | R | R | NA | R | NA | NADCAP | If the Supplier uses a process covered by one of the NADCAP families, the supplier shall have the process accredited by NADCAP. | ||||

| 7.5.2 | Validation of Processes for Production and Service Production | 7.5.2.10 | R | R | R | NA | R | NA | A proposed Qualification Test Plan shall accompany any supplier demand for [Manufacturer / Process] pair qualification. | |||||

| 7.5.2 | Validation of Processes for Production and Service Production | 7.5.2.15 | R | R | R | NA | R | NA | Any investigation and test linked to the use of non qualified processes or processes which are out of qualification will be charged to the Supplier. | |||||

| 7.5.2 | Validation of Processes for Production and Service Production | 7.5.2.20 | R | R | R | NA | R | NA | The supplier shall verify and maintain the technical qualification of industrial processes by industrial audits and ensure compliance with cascaded requirements. The periodic verification of special processes shall consist of monitoring the process parameters in an interval maximum of 1 year, in the process specification requirements. |

|||||

| 7.5.3 | Identification and Traceability | 7.5.3.05 | R | R | R | R | R | R | The delivery documentation shall include a delivery note. In the case of a closed box package, two Delivery Note shall be issued, one placed inside and the other oustside of the box. | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.07 | R | R | R | R | R | R | EN ISO/IEC 17050-1:2004 | The delivery documentation shall include a Statement of Conformity established according to EN ISO/IEC 17050-1:2004 or equivalent document, testifying the compliance with the P.O. specifications, and duly signed by the supplier's authorized personal. | ||||

| 7.5.3 | Identification and Traceability | 7.5.3.09 | R | R | R | R | R | R | The delivery documentation shall include copies of every Acceptance Test Reports required by product or procurement specification. | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.11 | R | R | NA | NA | NA | R | ARC Form | When applicable, the delivery documentation shall include the Autorized Released Certificate (Form 1) | ||||

| 7.5.3 | Identification and Traceability | 7.5.3.13 | R | R | R | R | R | R | The delivery documentation shall include any document, report, or certificate specificaly required by SONACA such as Control Memoranda, key characteristics report, or coupon test results… | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.15 | R | R | R | R | R | R | The delivery documentation shall include copies of approved concessions (NCR) and Manufacturing Changes (MC) . | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.20 | R | R | R | R | R | R | When partial or incomplete delivery [quantity difference, outstanding work or missing part] has been accepted by the buyer, the delivery documentation shall include a copy of the buyer written authorization. | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.25 | R | R | R | NA | R | R | When outstanding work have been required by the buyer, the exhaustive list of outstanding work or missing parts shall be referenced in the comment box of the declation of conformity. Work instructions shall be provided for outstanding work. | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.30 | R | R | NA | NA | R | R | When delivery has been required by the buyer without surface treatment or paint, a temporary identification plate or tied tag shall be attached to each delivered part. This ID plate shall contain all required information of final marking | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.35 | NA | NA | NA | NA | R | NA | Each cut shape shall be identified with a color code as follows : Blue for Aluminium alloys 7075, 7175 and 7475 Black for Aluminium alloys 7010, 7040 and 7050 Red for Aluminium alloys 2618 Green for Aluminium alloys 2024 and 2124 |

|||||

| 7.5.3 | Identification and Traceability | 7.5.3.37 | NA | NA | NA | NA | R | NA | The color spot identification shall be painted on the flange, on the corner where mounting holes are located, as per following typical sketch : |

|||||

| 7.5.3 | Identification and Traceability | 7.5.3.40 | R | R | R | R | R | R | Every product delivered to SONACA shall be identified. | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.42 | R | R | NA | R | R | R | Identification type, location and content shall comply with, by order of precedence : 1-Special requirement specified by the order, 2-Marking instructions specified by Condition of Supply, Manufacturing reserves or kit specification, 3-Marking instructions specified by design requirements or procurement specification, |

|||||

| 7.5.3 | Identification and Traceability | 7.5.3.44 | NA | NA | R | NA | NA | NA | Identification type, location and content shall comply with the provided work instruction. | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.46 | R | R | R | NA | R | R | Where a product delivery condition is required without surface treatment or paint, the part identification and traceability information shall be provided on a label attached by a wire to each part. | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.48 | R | R | R | R | R | R | Where no identification requirement is specified, a "bag & tag" labeling identification shall be applied. | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.50 | R | R | NA | R | R | R | The marked, engraved or labeled identification shall be consistent with the following minimum content : | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.52 | R | R | NA | R | R | R | - Manufacturer name, label or code | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.54 | R | R | NA | R | R | R | - SONACA Part or material number, as called out by the PO | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.55 | R | R | NA | R | R | R | - Batch or lot number | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.56 | R | R | NA | R | R | R | - Inspection stamp or label | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.58 | R | R | NA | R | R | R | - Individual serial number of serialized material | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.60 | R | R | NA | R | R | R | - Cure date for material subjected to limited shelf life | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.62 | R | R | NA | R | R | R | - Validity date for material subjected to limited lifetime | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.64 | R | R | NA | R | R | R | - Approved concessions references | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.66 | R | R | R | R | R | R | Indiviudal serial numbers of serialized parts and components shall be referenced on marking and declaration of conformity with the following syntax "SN123456789", without special character, dash, nor blank space. | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.68 | R | R | R | R | R | R | Ink jet or rubber stamp marking shall be protected by a transparent varnish qualified for aerospace usage. | |||||

| 7.5.3 | Identification and Traceability | 7.5.3.70 | R | R | R | R | R | R | Materials, products and standards shall be traceable throughout the whole manufacturing process and storage operations up to delivery. | |||||

| 7.5.4 | Customer Property | 7.5.4.05 | R | R | R | R | R | R | SONACA supplied goods shall be stored in a segregated area in order to prevent unauthorized use, and be adequately protected against damage and deterioration. | |||||

| 7.5.4 | Customer Property | 7.5.4.10 | R | R | R | R | R | R | SONACA supplied goods shall not be modified by the supplier without prior written consent from SONACA. | |||||

| 7.5.5 | Preservation of Product | 7.5.5.05 | R | R | R | R | R | R | Storage conditions shall be appropriate to ensure product preservation and integrity along its whole storage duration. | |||||

| 7.5.5 | Preservation of Product | 7.5.5.10 | R | R | R | R | R | NA | Suppliers shall have dedicated, secured and clearly identified area to ensure the segregation of: - Parts during incoming process (not inspected) - Not conform products - Customer returns |

|||||

| 7.5.5 | Preservation of Product | 7.5.5.15 | R | R | R | R | R | R | The Supplier shall set up a packaging ensuring the integrity and the non-deterioration of the parts during transportation. | |||||

| 7.5.5 | Preservation of Product | 7.5.5.20 | R | R | R | R | R | R | Specific storage condition (eg: temperature) shall be clearly and explicitly identified on the external side of the product packaging. | |||||

| 7.5.5 | Preservation of Product | 7.5.5.25 | R | R | R | R | R | R | The supplier shall submit to SONACA a packing approval report describing the packaging, protection, loading and un loading rules for parts subject to any risk of damage caused by transportation or handling. Packing Approval Report deliverable shall be agreed prior to first shipment. | |||||

| 7.5.5 | Preservation of Product | 7.5.5.30 | R | R | R | R | R | R | Delivery documentation shall be attached to the product and protected against loss or damage. | |||||

| 7.5.5 | Preservation of Product | 7.5.5.35 | R | R | R | R | R | R | The Supplier storage management shall be FIFO | |||||

| 7.5.5 | Preservation of Product | 7.5.5.8 | R | R | R | R | R | NA | Storage location of aerospace products, standards, and material shall be physically segregated from industrial (not airworthy) products. | |||||

| 8.0.0 | MEASUREMENT, ANALYSIS AND IMPROVEMENT | 8.0.0.01 | R | R | R | R | R | R | Corresponding 9100 series chapter and subsections are applicable.. |

|||||

| 8.1.4 | Prevention of counterfeit parts | 8.1.4.05 | R | R | R | R | R | R | EN9100:2016 §8.1.4 | Supplier shall demonstrate the compliance of its organization to EN9102:2016 requirements related to the prevention from counterfeit parts. | ||||

| 8.2.2 | Internal audit | 8.2.2.05 | R | R | R | R | R | R | The Supplier shall establish and maintain a quality audit program in his facilities to guarantee that the Purchaser’s requirements, as specified in the present document, are strictly applied. | |||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.05 | R | R | R | R | R | NA | PS 6.8003 | The conformity of metalic material heat condition shall be checked according to PS 6.8003. Measured values of conditivity or hardness shall be recorded. |

||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.10 | R | R | NA | R | R | R | ISO/IEC 17050-1:2004 | A Declaration of Conformity shall be raised as per EN ISO/IEC 17050-1:2004 requirements or equivalent document, testifying the compliance to P.O. specifications. Duly signed by the supplier's authorized personal, the declaration of conformity shall accompany each shipment to SONACA. |

||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.15 | R | R | NA | R | R | R | The declaration of conformity shall be consitent with product traceability information : Sonaca purchase order reference, ordered items, batch number, serial numbers of part and its consistutive components, acceptance test report reference and approved concessions shall be, when existing, registered on the declaration of conformity. | |||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.20 | R | R | NA | R | R | R | When shipment with outstanding work or missing parts are required by SONACA, the complete list of outstanding work and missing parts shall be declared on the declaration of conformity. A copy of the supplier job card and work instructions related to outstanding work shall be provided in the certificate appendix. |

|||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.25 | R | R | NA | NA | NA | R | EASA Part21 subpart G | Where required by SONACA, materials shall be delivered with an Autorized Release Certificate (airworthiness certificated) issued according to local Civil Aviation Autority rules and supplier part 21G certification. Concerned material shall be declared in the supplier CAA part 21G scope. |

||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.30 | NA | NA | NA | R | NA | NA | Copies of the OEM Acceptance Test Report and declaration of conformity shall accompany the retailer declaration of conformity. | |||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.35 | NA | NA | R | NA | NA | NA | The sonaca Job Card shall be attested in front of each performed operation and stamped as following in front of the last one : |

|||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.40 | R | R | R | R | R | R | Ordered product may be submitted to source inspection by the Purchaser’s Quality Department or its delegated, at supplier premises, before product shipment. When source inspection is required by SONACA, the Supplier shall inform SONACA of the date of product availability at least 5 working days earlier. |

|||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.45 | R | R | R | R | R | R | For the source inspection, all production and inspection operation shall be finished, and the product shall be presented in delivery condition, box opened. The supplier shall present the manufacturing job card, the First Article Inspection report, a copy of the purchase order, applicable concession or NCRs, the delivery documentation, inspection and CMM reports, and the validation dossier of toolings that contributes to product characteristics conformity | |||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.50 | R | R | R | R | R | R | Source inspections activated to secure supplier's default will be charged to supplier. SONACA reserves the right to request to Supplier an action plan to solve the problems identified, and to take appropriate actions to ensure problems resolution. |

|||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.55 | R | R | NA | NA | NA | R | The Class 1 and Special Control Parts shall be 100 % inspected at source by the Purchaser’s Quality department for at least the first three deliveries. Upon SONACA request, the number of deliveries can be extended. | |||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.60 | R | R | R | R | R | R | In the case of recurent lack of performance, a Quality Gate process shall be implemented by the Supplier in order to secure the quality of deliveries during the problem resolution process. | |||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.65 | R | R | R | R | R | R | EN9103 | Key Characteristics variation shall be controled according to EN/AS 9103 requirements. The method to control key characteristics shall be detailed in a Control Plan. |

||||

| 8.2.4 | Monitoring and Measurement of Product | 8.2.4.70 | R | R | NA | R | R | R | In case statistical process control is chosen to control Key Characteristics, Process Capability Studies deliverable become mandatory whatever the PPAP level. | |||||

| 8.3.0 | Control of Nonconforming Product | 8.3.0.05 | R | R | R | R | R | R | Unless otherwise specified by the Purchaser’s Quality department, no part/assembly will be delivered with an open nonconformity. | |||||

| 8.3.0 | Control of Nonconforming Product | 8.3.0.10 | NA | NA | NA | R | R | NA | Retailers shall be able to inspect product main characteristics according to specified requirements. | |||||

| 8.3.0 | Control of Nonconforming Product | 8.3.0.15 | NA | NA | NA | R | NA | R | Any nonconformity shall be documented on SONACA Non Conformity Report form and submitted to the Purchaser as request for concession. The request shall be addressed to: InspectionSoustraitance@sonaca.com | |||||

| 8.3.0 | Control of Nonconforming Product | 8.3.0.20 | R | R | R | NA | R | R | PDS-DQ-13.1.14 | Any nonconformity shall be submitted to the Purchaser as specified in IQS 13.1.7. and PDS-DQ-13.1.14. | ||||

| 8.3.0 | Control of Nonconforming Product | 8.3.0.25 | I | I | I | I | I | I | SONACA reserves the right to reject unacceptable, unclear or recurrent Concession Request without obligation to provide grounds for such a rejection. | |||||

| 8.3.0 | Control of Nonconforming Product | 8.3.0.30 | I | I | I | I | I | I | Addressing a Request for Concession to SONACA does not release the supplier from its P.O. or contract mandatory obligations, especially in terms of delivery date, quantity, condition of supplys and quality. | |||||

| 8.3.0 | Control of Nonconforming Product | 8.3.0.35 | R | R | R | R | R | R | Any nonconforming part/assembly shall be clearly identified with its approved NCR Reference. NCR number shall be referenced to the statement of conformity (refer to 7.5.3.64 requirement). | |||||

| 8.3.0 | Control of Nonconforming Product | 8.3.0.40 | R | R | R | R | R | R | When a non-conformity is identified after a Product released by the supplier, the Supplier shall immediatly inform SONACA with a "Notification of Escape" memorandum or disclosure letter. | |||||

| 8.3.0 | Control of Nonconforming Product | 8.3.0.45 | R | R | R | R | R | R | The notification shall include at a minimum : - Supplier name and location, - Clear description of the non-conformity, - Affected part number(s), - Delivered quantity, reference PO number, origin of PO and shipping date, - Date of manufacture, - Traceability information (serial number, batch number, work order...), - Inspection procedure, - Potential impact, - Root cause analysis, - Action plan. |

|||||

| 8.4.0 | Analysis of Data | 8.4.0.05 | R | R | R | R | R | R | The Supplier shall participate in regular “Supplier Management Meeting” organized by the Purchaser. | |||||

| 8.4.0 | Analysis of Data | 8.4.0.10 | R | R | R | R | R | R | QRS 00.00 "Suppliers Quality Scorecard" sheet | To support the Supplier Management Meeting, the Supplier shall monitor and review its own "Quality Performance Indicators" compared with those calculated by SONACA. If the Supplier disagrees with the data provided by SONACA, he shall provide evidence to support his own data. Details on SONACA Quality Delivery metrics can be requested to SONACA Supplier Quality Development person of contact. | ||||

| 8.4.0 | Analysis of Data | 8.4.0.15 | R | R | R | R | R | R | To support the Supplier Management Meeting, the Supplier shall present the list of non-conformities with the root causes analysis and the corrective/preventive actions. | |||||

| 8.4.0 | Analysis of Data | 8.4.0.20 | R | R | R | R | R | R | When required by SONACA, Supplier shall provide the appropriate quality data (charts, indicators, acceptance rate, shop records, etc.) that demonstrates supplier's internal quality performance and the corrective actions taken in order to prevent impacts at SONACA. | |||||

| 8.4.0 | Analysis of Data | 8.4.0.25 | I | I | NA | I | I | I | QRS 00.00 "Suppliers Quality Scorecard" sheet | Yearly targets are set with Suppliers : PPM (non-conform parts per million delivered parts), quantity of quality escapes, lead time to close quality claims and quantity of concessions requets. Targets are set as maximum value not to be exceeded. SONACA rates monthly Suppliers quality performance versus each yearly target on the Suppliers Quality Scorecards. An overall Quality rating [A-B-C-D] is then allocated to the supplier. | ||||

| 8.4.0 | Analysis of Data | 8.4.0.30 | I | I | NA | I | I | I | QRS 00.00 "Suppliers Quality Scorecard" sheet | Rating A: Customer expectations are fully met. Supplier monitoring shall be mainly focused on preventive or sourcing actions and product conformity management. Business development activities take place with rating A Suppliers. | ||||

| 8.4.0 | Analysis of Data | 8.4.0.35 | R | R | NA | R | R | R | QRS 00.00 "DELTA PPAP" sheet | Rating B: Customer expectations are partially met, meaning that one or several target values are nearly achieved or slightly exceeded. Supplier monitoring may be reinforced as required. Business development may be subject to validation of a quality development plan to achieve rating A. | ||||

| 8.4.0 | Analysis of Data | 8.4.0.40 | R | R | NA | R | R | R | QRS 00.00 "Suppliers Quality Scorecard" sheet | Rating C: Customer expectations are not met, meaning that one or several quality targets values are clearly exceeded. Supplier shall implement a quality improvement plan to achieve yearly targets, content and follow-up process to be validated with SONACA. SONACA shall reinforce Supplier monitoring and may place the Supplier under surveillance or probation. Business development shall be subject to validation of a quality development plan to achieve rating A. | ||||

| 8.4.0 | Analysis of Data | 8.4.0.45 | R | R | NA | R | R | R | QRS 00.00 "Suppliers Quality Scorecard" sheet | Rating D: One or several quality target values are largely exceeded, which may jeopardize SONACA performance towards its Customers. The Supplier shall implement a quality performance recovery plan to improve its rating to an acceptable and agreed performance level. The Supplier shall submit a follow-up status report as defined and agreed with SONACA. SONACA may place the Supplier under surveillance or probation. SONACA Quality will object to any business development. | ||||

| 8.4.0 | Analysis of Data | 8.4.0.46 | R | R | R | R | R | R | Being placed under surveillance, Supplier shall implement an action plan so that Sonaca regains confidence in the Supplier Quality Management System, product conformance and process control. Amongst these actions, SONACA may request the following, but not limited to : implementation of quality wall at Supplier, supply of evidence of specific quality inspection on each product delivered... SONACA shall define conditions to exit from surveillance status when surveillance status is notified to the Supplier. Audit, assessment or visit frequency may be increased as required. | |||||

| 8.4.0 | Analysis of Data | 8.4.0.50 | R | R | R | R | R | R | Probation : SONACA shall notify the Supplier put on probation with an official letter stating the reason for probation, consequences for the Supplier and conditions to exit the probation status. No new contract or bid sollicitation shall be placed to the Supplier. SONACA may at its sole discretion assign a SONACA employee or a third party to manage and oversee the Supplier's action plan at the Supplier's facility, at Supplier's expenses. Source inspection shall be required for the duration of the probation, at Supplier's expenses. | |||||

| 8.4.0 | Analysis of Data | 8.4.0.55 | R | R | R | R | R | R | When Supplier is placed under surveilance or in case of recurrent similar conformity issues, each order may be subject to source inspection by a SONACA employee or a third party, at Supplier's expenses. Conditions to stop source inspections shall be defined by SONACA when source inpection process is notified to the Supplier. | |||||

| 8.5.2 | Corrective Action | 8.5.2.05 | R | R | R | R | R | R | The supplier shall take every necessary actions to secure the supply chain : containment actions (such as inventories check…), root cause analysis, corrective action & effectivity check. | |||||

| 8.5.2 | Corrective Action | 8.5.2.07 | R | R | R | R | R | R | Supplier's disagreements to a SONACA quality or logistic claim (usually 8D or QRQC form) shall be expressed within 2 working days after receiving the notification. Otherwise, supplier accepts the responsibility of the nonconformity report. The deadline for acceptance could be negociated with supplier quality engineer for parts requiring specific tests. |

|||||

| 8.5.2 | Corrective Action | 8.5.2.10 | R | R | R | R | R | R | The supplier shall follow the directions of quality claims such as the QRQC and the 8D adressed by SONACA, provide immediate countermeasures within 2 working days and implement a corrective action plan within 3 weeks. Reduced deadlines can be required by SONACA for operational reasons and specified in the QRQC / 8D. |

|||||

| 8.5.2 | Corrective Action | 8.5.2.15 | I | I | I | I | I | I | International Aerospace Quality Group Supply Chain Management Handbook | Suppliers can find guidance for problem solving methodology on the IAQG website - Supply Chain Management Handbook (http://www.sae.org/iaqg) | ||||

| 8.5.2 | Corrective Action | 8.5.2.20 | R | R | R | R | R | R | For rework, repair, retrofit or stock screening performed at SONACA or its customers facilities, Supplier shall comply with access rights rules and requirements provided by SONACA. | |||||

| 8.5.3 | Preventive Action | 8.5.3.05 | R | R | R | R | R | R | In case of findings or suspicion of any deviation that might impact the quality of product or service already delivered, SONACA Quality Department shall be informed without delay. Upon request, the supplier shall support SONACA's inquiries by providing any technical or quality assistance. | |||||

| LEGEND = | R : Applicable requirement - Supplier compliance shall be demonstrated I : Information provided to supplier - No compliance demonstration required NA : Not applicable requirement |

|||||||||||||

| Revision C: dated from 05/2017 | ||||||||||||||||||||||||||

| SONACA APQP PHASE |

PHASE 1 PLANNING |

PHASE 2 PRODUCT DESIGN & DEVELOPMENT |

PHASE 3 PROCESS DESIGN & DEVELOPMENT |

PHASE 4 PRODUCT & PROCESS VALIDATION |

PHASE 5 PRODUCTION |

|||||||||||||||||||||

| Name | PLANNING SOURCING & NEGOCIATION |

PRODUCT DESIGN & DEVELOPMENT ORDER |

PROCESS DESIGN & DEVELOPMENT INDUSTRIALIZATION |

PRODUCT & PROCESS VALIDATION MANUFACTURING, DELIVERY & RECEPTION |

PRODUCTION HAND OVER |

PRODUCTION RAMP UP |

||||||||||||||||||||

| 1A | 1B | 1C | 1D | 2A | 2B | 3A | 3B | 4A | 4B | 4C | 4D | 5A | 5B | |||||||||||||

| Intermediate Milestones |

Technical Spec/Design Principle Concept Frozen MILESTONE A |

Readiness For RFQ | RFQ Review | Award | PO Review | PDR Product Design Verified and Validated |

CDR Definition Released by the supplier if design MILESTONE B |

Manuf. Readiness Review/ GO PROD | First Production | First Devlivery Acceptance |

Delivery MILESTONE D |

Reception PPAP MILESTONE E |

Hand Over & Pre Series | Ramp Up & Serial Production | ||||||||||||

| Gate Reviews | ||||||||||||||||||||||||||

| FULL SUBCONTRACTOR (Design & Built) PPAP Delivrables |

Feasability Commitment | Feasability Commitment | DFMEA | R&R | DFMEA | PFMEA | PPAP CERTIFICATE INTERIM APPROVAL | Layout | ||||||||||||||||||

| Detailed Planning | Detailed Planning | Layout | Process Capability Studies | Layout | Workforce Capacity Plan | PFMEA | ||||||||||||||||||||

| scope matrix signed | Process flow Diagram | Tooling & checking aids report | Process flow Diagram | Dimensional Report | Control Plan | |||||||||||||||||||||

| PFMEA | Special Process Qualification | PFMEA | FPQ /QTP ( report) | Tooling & checking aids report | ||||||||||||||||||||||

| Control Plan | Sub tiers Management | Control Plan | ALT report | Workforce Capacity Plan | ||||||||||||||||||||||

| ALT Plan | FPQ /QTP( plan) | R&R | HASS report | PPAP CERTIFICATE APPROVAL | ||||||||||||||||||||||

| HASS plan | ATP approval report | Tooling & checking aids report | ATP approval report | Process Capability Studies | ||||||||||||||||||||||

| REQUIRED MATURITY LEVEL : | Packing Approval Report | Visual Aspect Report | Process Capability Studies | |||||||||||||||||||||||

| PRELIMINARY | Workforce Capacity Plan | Material Test Result | Visual Aspect Report | |||||||||||||||||||||||

| COMPLETE | ALT Plan | Special Process Qualification | ||||||||||||||||||||||||

| UPDATE | HASS plan | Sub tiers Management | ||||||||||||||||||||||||

| Packing Approval Report | ||||||||||||||||||||||||||

| Workforce Capacity Plan | ||||||||||||||||||||||||||

| ATP approval report | ||||||||||||||||||||||||||

| Built - to - Print Suppliers PPAP Delivrables |

Feasability Commitment | Feasability Commitment | Layout | Layout | PPAP CERTIFICATE INTERIM APPROVAL | Layout | ||||||||||||||||||||

| Detailed Planning | Detailed Planning | Process flow Diagram | Process flow Diagram | PFMEA | ||||||||||||||||||||||

| Layout | PFMEA | PFMEA | Control Plan | |||||||||||||||||||||||

| Process flow Diagram | Control Plan | Process Capability Studies | Tooling & checking aids report | |||||||||||||||||||||||

| PFMEA | R&R | Dimensional Report | Workforce Capacity Plan | |||||||||||||||||||||||

| Control Plan | Process Capability Studies | FPQ /QTP ( report) | PPAP CERTIFICATE APPROVAL | |||||||||||||||||||||||

| R&R | Tooling & checking aids report | ALT report | Process Capability Studies | |||||||||||||||||||||||

| Tooling & checking aids report | Special Process Qualification | HASS report | ||||||||||||||||||||||||

| Special Process Qualification | Sub tiers Management | ATP report | ||||||||||||||||||||||||

| REQUIRED MATURITY LEVEL : | Sub tiers Management | Packing Approval Report | Visual Aspect Report | |||||||||||||||||||||||

| PRELIMINARY | FPQ/QTP plan | Workforce Capacity Plan | Material Test Result | |||||||||||||||||||||||

| COMPLETE | ATP plan | ATP plan | ||||||||||||||||||||||||

| UPDATE | Packing Approval Report | Visual Aspect Report | ||||||||||||||||||||||||

| Workforce Capacity Plan | ALT plan | |||||||||||||||||||||||||

| ALT plan | HASS plan | |||||||||||||||||||||||||

| HASS plan | ||||||||||||||||||||||||||

no reviews yet

Please Login to review.