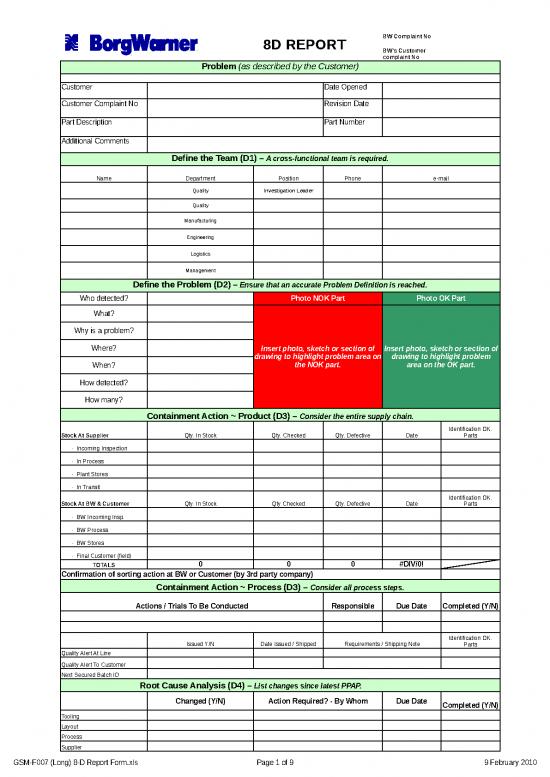

| 8D REPORT |

BW Complaint No |

|

| BW's Customer complaint No |

|

| Problem (as described by the Customer) |

|

| Customer |

|

Date Opened |

|

| Customer Complaint No |

|

Revision Date |

|

| Part Description |

|

Part Number |

|

| Additional Comments |

|

| Define the Team (D1) – A cross-functional team is required. |

| Name |

Department |

Position |

Phone |

e-mail |

|

Quality |

Investigation Leader |

|

|

|

Quality |

|

|

|

|

Manufacturing |

|

|

|

|

Engineering |

|

|

|

|

Logistics |

|

|

|

|

Management |

|

|

|

| Define the Problem (D2) – Ensure that an accurate Problem Definition is reached. |

| Who detected? |

|

Photo NOK Part |

Photo OK Part |

| What? |

|

Insert photo, sketch or section of drawing to highlight problem area on the NOK part. |

Insert photo, sketch or section of drawing to highlight problem area on the OK part. |

| Why is a problem? |

|

| Where? |

|

| When? |

|

| How detected? |

|

| How many? |

|

| Containment Action ~ Product (D3) – Consider the entire supply chain. |

| Stock At Supplier |

Qty. In Stock |

Qty. Checked |

Qty. Defective |

Date |

Identification OK. Parts |

| · Incoming Inspection |

|

|

|

|

|

| · In Process |

|

|

|

|

|

| · Plant Stores |

|

|

|

|

|

| · In Transit |

|

|

|

|

|

| Stock At BW & Customer |

Qty. In Stock |

Qty Checked |

Qty. Defective |

Date |

Identification OK. Parts |

| · BW Incoming Insp. |

|

|

|

|

|

| · BW Process |

|

|

|

|

|

| · BW Stores |

|

|

|

|

|

| · Final Customer (field) |

|

|

|

|

|

| TOTALS |

0 |

0 |

0 |

#DIV/0! |

|

| Confirmation of sorting action at BW or Customer (by 3rd party company) |

|

| Containment Action ~ Process (D3) – Consider all process steps. |

| Actions / Trials To Be Conducted |

Responsible |

Due Date |

Completed (Y/N) |

|

|

|

|

|

|

|

|

|

Issued Y/N |

Date Issued / Shipped |

Requirements / Shipping Note |

Identification OK. Parts |

| Quality Alert At Line |

|

|

|

|

| Quality Alert To Customer |

|

|

|

|

| Next Secured Batch ID |

|

| Root Cause Analysis (D4) – List changes since latest PPAP. |

|

|

Changed (Y/N) |

Action Required? - By Whom |

Due Date |

Completed (Y/N) |

| Tooling |

|

|

|

|

| Layout |

|

|

|

|

| Process |

|

|

|

|

| Supplier |

|

|

|

|

|

| Other |

|

|

|

|

| Root Cause Analysis (D4) – List the ‘TRUE’ root cause(s) from Ishikowa, FTA, 5 Why. |

% Contribution |

|

|

|

|

|

|

|

|

| Chosen Corrective Actions (D5) – Where possible, reproduce the failure. |

| Actions / Trials To Be Conducted |

Responsible |

Due Date |

Completed (Y/N) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Implement Chosen Corrective Actions & Verify (D6) – Ensure that verification methods are implemented and assessed to support all corrective actions (retain all verification data) |

| Action |

Date Implemented |

Verification Method |

% Effective |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Implement chosen Preventive Actions & verify (D7) – Ensure that verification methods are implemented and assessed to support all corrective actions (retain all verification data). |

| Action |

Date Implemented |

Verification Method |

% Effective |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Implement Systemic Preventive Actions (D7) – Consider ALL similar products and processes affected by the proven implemented changes (Is change control or Customer notification required?). |

| Additional Actions |

Indicate yes or no

YES/NO |

IF YES, LIST DOCUMENT

IF NO, EXPLAIN WHY NOT NEEDED |

Date Implemented |

| Amend Process Flow Diagram: |

|

|

|

| Amend D/PFMEA: |

|

|

|

| Amend Control Plan: |

|

|

|

| POKA-YOKE Implemented: |

|

|

|

| Update Drawing: |

|

|

|

| Update Work Instructions: |

|

|

|

| Update Other (list): |

|

|

|

| Training Completed |

|

|

|

| Additional Action |

|

|

|

| Can / were specified changes applied to addition / similar part #'s, or procedures? |

| Was requalification documentation reviewed to verify that there have not been any unauthorized changes since the last PPAP? |

| Additional Action Plans |

| Action required |

By Whom |

When |

Completed |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Congratulate the Team (D8) – Recognize the team for their efforts. |

| Action Taken |

By Whom |

When |

Completed |

|

|

|

|

| Initial Close Out – Ensuring that all corrective & preventive actions are in place as described. |

| Team Members: |

| Leader: |

|

Date |

|

| Quality Manager: |

|

Date |

|

| Customer Approval (Optional) |

| Customer Name |

Customer Responsible |

Date |

Report No. |

|

|

|

|

Final Effectiveness Process – By means of a planned audit of the section, process or product

(approx. 3 months after the initial closure date). |

| Audit Type and Reference Document. |

Date Planned |

Audited By |

Date |

|

|

|

|

|

|

|

|

| Diary Of Events: |

| Details |

Date |

|

|

|

|

|

|

|

|