192x Filetype XLSX File size 0.05 MB Source: www.ttieurope.com

Sheet 1: Supplier Daily Updates

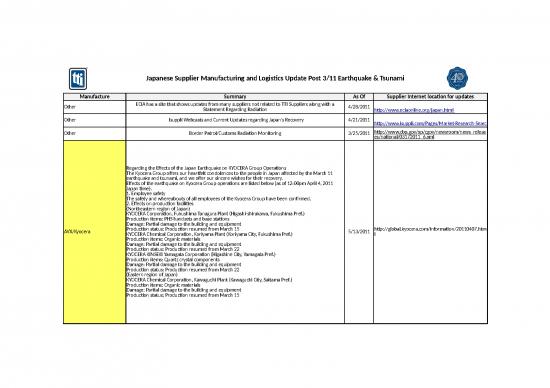

| Japanese Supplier Manufacturing and Logistics Update Post 3/11 Earthquake & Tsunami | |||

| Manufacture | Summary | As Of | Supplier Internet location for updates |

| Other | ECIA has a site that shows updates from many suppliers not related to TTI Suppliers along with a Statement Regarding Radiation | 4/28/2011 | http://www.eciaonline.org/japan.html |

| Other | Isuppli Webcasts and Current Updates regarding Japan's Recovery | 4/21/2011 | http://www.isuppli.com/Pages/Market-Research-Search-News.aspx |

| Other | Border Patrol/Customs Radiation Monitoring | 3/25/2011 | http://www.cbp.gov/xp/cgov/newsroom/news_releases/national/03172011_6.xml |

| AVX/Kyocera | Regarding the Effects of the Japan Earthquake on KYOCERA Group Operations The Kyocera Group offers our heartfelt condolences to the people in Japan affected by the March 11 earthquake and tsunami, and we offer our sincere wishes for their recovery. Effects of the earthquake on Kyocera Group operations are listed below (as of 12:00pm April 4, 2011 Japan time). 1. Employee safety The safety and whereabouts of all employees of the Kyocera Group have been confirmed. 2. Effects on production facilities (Northeastern region of Japan) KYOCERA Corporation, Fukushima Tanagura Plant (Higashi-shirakawa, Fukushima Pref.) Production items: PHS handsets and base stations Damage: Partial damage to the building and equipment Production status: Production resumed from March 15 KYOCERA Chemical Corporation, Koriyama Plant (Koriyama City, Fukushima Pref.) Production items: Organic materials Damage: Partial damage to the building and equipment Production status: Production resumed from March 22 KYOCERA KINSEKI Yamagata Corporation (Higashine City, Yamagata Pref.) Production items: Quartz crystal components Damage: Partial damage to the building and equipment Production status: Production resumed from March 22 (Eastern region of Japan) KYOCERA Chemical Corporation, Kawaguchi Plant (Kawaguchi City, Saitama Pref.) Production items: Organic materials Damage: Partial damage to the building and equipment Production status: Production resumed from March 15 |

5/13/2011 | http://global.kyocera.com/information/20110407.html |

| Bourns | On March 23, 2011, Bourns, Inc. ("Bourns") provided its customers with an update regarding the impact on Bourns’ business resulting from the aftermath of the March 11, 2011 earthquake in Japan. In that update Bourns noted that slight delays might occur due to cargo screening for radiation. Bourns is aware of continued customer concerns regarding the threat of radiation contamination to Bourns® products and/or raw materials exported from or manufactured in Japan. Bourns does not own manufacturing facilities in the affected areas of Japan; however, Bourns utilizes certain sub-suppliers which have been directly or indirectly impacted by the earthquake. The majority of Bourns® products and raw materials are being screened by Bourns’ carriers before leaving Japan. At this time, Bourns is pleased to report that we are not aware of any Bourns® products or raw materials showing any radiation contamination. Bourns will continue to closely monitor the situation at the Fukushima nuclear facility and we will update this advisory in the event there is any material change to the Bourns’ supply chain. |

4/6/2011 | http://www.bourns.com/PressReleases.aspx?name=110331_japanese_earthquake_crisis_update |

| Cooper Bussman | Please be advised this communication is to confirm there is no current impact to Cooper Bussmann global routing of freight or shipments via any mode related to the current crisis in Japan. All freight is moving through normal transit channels without delay. | 3/16/2011 | Not applicable at this time |

| Cornell Dubilier (CDE) * | While CDE manufactures some products in Japan and the Pacific Rim, we have been advised that all of our factories are back to normal production. We are uncertain about what effect this disaster will have on our raw material orders and our shipping ports but at this time we believe our business will not be impacted | 6/5/2011 | www.cde.com |

| Delphi | Official letter states there are anticipated delays, but no major issues related to Japan issue. | 3/21/2011 | Not applicable at this time |

| EPCOS * | Whereas EPCOS operates no plants of its own in Japan, several of its suppliers have production facilities there. The degree to which these facilities are now affected varies from case to case. To the best of our knowledge right now, it is nevertheless reasonable to assume that EPCOS' components production will not be affected to any significant extent. This situation may change depending on developments in Japan – due to restricted power supply, for example. EPCOS remains in constant contact with its suppliers and is doing everything in its power to organize alternative supply channels if required. Whereas EPCOS operates no plants of its own in Japan, several of its suppliers have production facilities there. The degree to which these facilities are now affected varies from case to case. To the best of our knowledge right now, it is nevertheless reasonable to assume that EPCOS' components production will not be affected to any significant extent.This situation may change depending on developments in Japan – due to restricted power supply, for example. |

6/5/20111 | http://www.epcos.com/web/generator/Web/Sections/Home/JP/Statement,locale=en.html |

| FCI | FCI Japan KK Headquarters - Tokyo, Japan: This sales, engineering and business office is fully staffed and focused on FCI's earthquake recovery. FCI Japan KK Ishioka Site (100km NE of Tokyo): This manufacturing location, dedicated to FCI's Electronics Dicvision, sustained large tremors with limiited structural damage. Power was restored today and machines are being evaluated for production and restart as soon as possible. The Ishioka Site is 1 of 9 FCI Electronics manufacturing sites worldwide. Production from Ishioka site and local suppliers is mainly focused on the following production- FFC/FPC, Mobile Phone Connectors, BTFM/BTFW/BTEM and PHEC/PHEN. Suppliers/Subcontractors (all FCI divisions), various Japan locations: This concerns primarily our Electronics Division, FCI has made contact with each strategic supplier and subcontractor. Most were not impacted by the earthquake. However, there are some reports of structural damage, tsunami flooding and evacuations due in particular to the Fukushima nuclear plant. FCI is evaluating supply chain disruptions and possible options. | 3/18/2011 | Not applicable at this time |

| Kemet * | June 2, 2011- As with our last update on March 22, 2011, we have continued to monitor and react to the situation in Japan very closely. With over two months having elapsed since the events in Japan, KEMET has maintained sufficient key componentry for all operations. Thanks to an amazing rate of progress by the Japanese people to restore power, supply lines and infrastructure, we are pleased to report that, based on the information available to us, we do not foresee any material supply issues relating to this event. Per Loof Chief Executive Officer |

6/5/2011 | http://www.kemet.com/kemet/web/homepage/kechome.nsf/WebEn/86672365A27AF39F8525785B0078F5A2 |

| KOA | Operation of KOA facilities All Plants and Sales Offices of KOA Group are in operation except below-mentioned facilities Tama Electric Co.,Ltd.,Fuchu Facilities 4-5 Yazaki-cho Fuchu City,Tokyo TEL:042‐364‐8321 FAX:042‐366‐0411 Said Facilities are in the area of the rolling blackout implemented by Tokyo Electric Power Company, and they are making operation adjustment including the shift. Remarks: Sendai Branch(Miyagi Pref.) and Mito Branch(Ibaragi Pref.) have been in operation since March 24,2011, after they tentatively closed down due to the impact of the Earthquake. |

4/21/2011 | http://www.koanet.co.jp/eastjapan-earthquake/eastjapan-earthquake.en.htm |

| Littelfuse | Littelfuse is continuing to work with their supply base to understand any potential impacts to our supply chain as a result of this tragedy.Littelfuse does not have any manufacturing operations in Japan and we can confirm that none of our facilities were directly impacted by the earthquake. Our direct supply base is limited in Japan and they have been in contact with their rntire supply base to assure that there are no short term disruptions. If they become aware of any specific supply information that will impact their ability to deliver products, they will contact those specific customers affected. | 3/23/2011 | Not applicable at this time |

| Molex | Our manufacturing operations are operating normally today. | 3/15/2011 | www.molex.com/mx_upload/editorial/910/20110314_japan.pdf |

| Murata * | About the recommencement of factory operations (Final report) Kanazawa Murata Manufacturing Co., Ltd. Sendai Plant has resumed production on May 23. All Murata factories that suffered damage in the disaster are now back in operation. Kanazawa Murata Manufacturing Co., Ltd. Sendai Plant Address 2-6, Akedori 3-chome, Izumi-ku, Sendai-shi, Miyagi 981-3206 Japan Products Piezoelectric Products and SAW filters Restoration The production of all items has resumed from Monday, May 23. Message from President Tsuneo Murata I extend my deepest condolence to everyone affected by the recent Eastern Japan earthquake, and pray for the swift recovery and restoration from the disaster. Murata Manufacturing Company, Ltd. Oyama Plant, Tome Murata Manufacturing Co., Ltd., and Kanazawa Murata Manufacturing Co., Ltd. Sendai Plant also suffered damage in the earthquake, but all three factories are now back in operation as of May 23, following the restoration of operations at the Oyama Plant on March 28, Tome Murata Manufacturing on March 29, and the Kanazawa Murata Manufacturing Sendai Plant on May 23. I wish to thank all our customers, suppliers, and staff for their heartfelt words of sympathy and encouragement, and their tireless support and cooperation in our restoration efforts. With renewed commitment, we shall continue to provide values that exceed customer expectations and do our best to show the world that Japanese electronic parts manufacturers have the strength to overcome any crisis. |

5/23/2011 | http://www.murata.com/new/info/2011/0418/index.html |

| Nichicon | The 3rd report: Nichicon has one plant in the general area of the disaster which is located in Iwate Prefecture. There are no personnel affected at this site and all the production equipment at NICHICON. (IWATE) CORPORATION (Iwate prefecture) has been completely inspected and has resumed operation March 17th. Regarding all our other Nichicon factories in Japan we can inform that there is no damage affecting the plant operations in our domestic group companies as of 10:00am on March 14,2011. There are no personnel affected by this disaster and no big damage affecting our operations at any sites in our domestic group companies but because of restriction on the procurement of materials and transportation etc, we anticipate that our shipments will be delayed. Nichicon has sent an official letter suggesting that materials associated with the manufacturing of Aluminum Electrolytics, raw material is becomming very difficult to procure. This is impacting thier ability to produce. | 4/21/2011 | http://nichicon-us.com/english/index.html |

| Ohmite | We are currently assessing where we stand on elements and components we purchase through Japan, which parts are listed above. At this point it is still not clear how our supply chain may be affected. We will keep you appraised of the status on all part series when we know the facts. OX / OY LVK LVC FCSL RW1SOCK 60S SMD OA / OD / OF MOX 200 / MOX 300 |

3/18/2011 | Not applicable at this time |

| Omron | There has only been limited damage to offices etc. and these workplaces will all be fully operational once the condition of mass transport and electrical infrastructure has been improved. | 3/17/2011 | www.omron.com/media/press/2011/03/c0315.html |

| Panasonic Industrial Components * | To help cut power consumption amid concerns of power shortage, Panasonic has been rigorously enforcing electricity-saving measures by calling out to all Panasonic ofices and factories in Japan to turn off lighting and other electric equipment that are not in absolute need as well as to turn off outdoor signage of it's buildingd across the nation since March 12, 2011. Impact on Production: Fukushima Factory in Fukushima Prefecture and Sendai Factory in Miyagi Prefecture of AVC Networks Company partially resumed production on April 1,2011. Placing priority on the safety of its employees and cooperating with the planned power outages scheduled by Tokyo Electric Power Co. TEPCO and Tohoku Electric Power Co., Panasonic is resuming operations in teh affected region. SANYO Electric Co, LTD Tokyo Plant in Gunma Prefecture resumed production on March 14,2011. Yamagata Factory in Yamagata Prefecture and Utsunomiya Factory in Tochigi Prefecture of AVC Networks Company partially resumed production on March 22.2011. Panasonic resumed production on March 23, 2011 | 4/21/2011 | http://panasonic.net/news/2011/20110314.html |

| Panasonic Electric Works | Panasonic Electric Works ACBU manufacturing facilities in Japan have reported no major physical damage from the recent earthquake._x000D_ Panasonic is currently working with our suppliers to evaluate the material supply chain and how it may impact production. Given the severity of the disaster, this process may take some time before we have a clear picture of the overall status. |

3/25/2011 | http://news.panasonic.net/archives/2011/0312_4524.html |

| Sumitomo | in Japan confirmed that our plants were not affected but due to power outrages they have not being able to start working and until these issues are resolved we should be able to get more information in case we foresee any material shortages. | 3/17/2011 | Not applicable at this time |

| TDK * | See attached. | 6/5/2011 | http://www.global.tdk.com/news_center/news/20110414_1.htm |

| TE Connectivity (Formerly TYCO) | Dear Valued Distributor, TE Connectivity (TE) extends our heartfelt condolences to those in and around Japan during this difficult time. Thankfully all of our employees have been accounted for and are safe. Our facilities in Japan had minimal damage and are operational. In the coming days, we will continue to monitor the news coverage and receive frequent reports from TE leadership in Japan about our employees, suppliers and customers. As of now, only a limited number of our products are impacted by supply chain issues caused by the tragedy. If your products or delivery are affected, you will be contacted by your sales representative with with further details. Your patience and support during this time is greatly appreciated. Thank you and best regards, Dave Redfern, Vice President, TE Distribution Channel |

4/6/2011 | http://www.tycoelectronics.com/crisis/default.asp |

| TT Electronics (IRC/BI/ect.) | According to official letter from TT Elect there is no impact from Japan issues. | 4/28/2011 | Not applicable at this time |

| Toshiba | Kimitsu City, Mobara City, Chiba Prefecture - The building is partly but not badly damaged. Operation is stopped and they will respond on a part by part basis. They have a list of our backlog and are reviewing. | 4/28/2011 | www.toshiba.co.jp/about/press/index.htm |

| United Chemi-Con | The Final Report From Nippon Chemi-Con: Notice Regarding Full Recovery From the Great East Japan Earthquake Two months have passed since theMarch 11. 2011, Great East Japan Earthquake and the massive Tsunami disaster. As a result of ongoing efforts, we hereby announce that our production capacity has resumed to pre-earthquake status as of May 19,2011. | 6/5/2011 | http://www.chemi-con.co.jp/e/index.html |

| Vishay * | Vishay has noted some Mosfets were affected. The March 11 2011 Earthquake and subsequent events in Japan have caused some materials shortages in the supply chain. In most cases this has been transparent with our policy of dual sourcing, however we have identified a shortage in a key Epoxy Material used in the assembly of a limited set of Vishay Mosfet products. In order to keep continuity of supply Vishay plans to transfer production to an existing alternate set of materials on these specific part types until the supply of this key Epoxy can resume. The list of parts that is affected is attached along with the new part type for the alternate set of materials, in most cases both sets of materials have been previously approved and supplied to our customers. In order to keep receiving product the backlog needs to be transferred to the alternate part number. We are expecting this action to potentially last for some time until normal production can resume, we are monitoring the supply and will provide updates as the situation improves. Vishay is in contact with their supply chain and once they are informed, they will advise details.Vishay has not yet been informed of any impact to its suppliers’ factories. Vishay’s Purchasing department is compiling data on the status of all its suppliers in order to monitor and avert or minimize potential disruptions to logistics and other functions. These suppliers will need time to review and assess their situations. |

4/28/2011 | Not applicable at this time |

| Wima | We have immediately checked the risk exposure of our supply chain to the current disaster situation in Japan. As a result we can confirm that WIMA has neither a single source position nor a direct or indirect dependency on Japanese suppliers with regard to all types of PET and PP raw material used in our capacitors. Therefore we don't see -at least for the time being- any restrictions with regard to our material supply or lead times. Until now we have no alerting information regarding the supply of PPS raw material (for WIMA SMD-PPS series only) which is produced by a Japanese company – however, based on our latest information PPS is produced outside Japan. | 3/21/2011 | Not applicable at this time |

| Yageo | No impact from Japan issues. | 3/21/2011 | Not applicable at this time |

| 3M | Our factories are currently without power and shipments out of our warehouses are severely limited at this moment. Assessments by the Engineering team will confirm the safety of the buildings, but caution is being taken due to the severity of the aftershocks. | 3/15/2011 | Not applicable at this time |

| UPS * | See attached. | 6/5/2011 | http://www.ups.com/content/us/en/about/news/service_updates/20110509_earthquake.html |

| FED-EX | Pickup and delivery services in eastern Japan have resumed with the exception of Fukushima, Miyagi, and parts of Ibaraki prefectures. The embargo on all inbound shipments to eastern Japan, Guam, Okinawa and Saipan have been lifted. We would like to thank our customers for their understanding in this matter. To obtain information on the status of your package, customers may visit fedex.ca and enter the package tracking number or call customer service at 1.800.GoFedEx 1.800.463.3339. | 3/22/2011 | www.fedex.com/ca_english/news/japanservicedisruption.html |

| Related Japan Business Update ** | Hamaoka No. 4 Reactor Shut Down TEPCO to Cover NO.1 reactor building at the Fukushima Daiichi Plant | 5/13/2011 | http://www3.nhk.or.jp/daily/english/13_29.html |

| yahoo | www.finance.yahoo.com/news/Business-apf-3530195807.html?x=0&.v=2 | 3/15/2011 | |

| Related Japan Business Update | Japan Earthquake Impacts Several Major IT Suppliers from Korea | 3/25/2011 | http://www.digitimes.com/Reports/Report.asp?datepublish=2011/03/22&pages=VL&seq=203 |

| Related Japan Business Update | Sony PS3 production May Run Tight due to Laser Diodes | 3/25/2011 | http://www.digitimes.com/Reports/Report.asp?datePublish=2011/3/24&pages=VL&seq=201 |

| Related Japan Business Update | Rare earth price could fall after Japan quake: exec | 3/15/2011 | www.reuters.com/article/2011/03/15/us-usa-rareearth-idUSTRE72E6HL20110315 |

| Related Japan Business Update | Tech Supply Shortages Loom After Japan Earthquake | 3/15/2011 | http://techland.time.com/2011/03/15/japan-earthquake-tech-supply-shortages/ |

| Related Japan Business Update | Chip prices up after Japan earthquake, tsunami, nuclear meltdown fears | 3/15/2011 | http://blogs.computerworld.com/17978/chip_prices_up_after_japan_earthquake_tsunami_nuclear_meltdown_fears?ub |

| Related Japan Business Update | Japanese Earthquake Impacts Component Supply & Pricing | 3/15/2011 | www.pcb007.com/pages/zone.cgi?a=75196 |

| Related Japan Business Update | The Impact of Japan’s Earthquake on the Electronics and Semiconductor Industries | 3/15/2011 | www.glgroup.com/News/The-Impact-of-Japans-Earthquake-on-the-Electronics-and-Semiconductor-Industries-52958.html |

| Related Japan Business Update | Tech companies pitch in on earthquake response | 3/16/2011 | http://news.yahoo.com/s/ap/20110315/ap_on_hi_te/us_tec_japan_earthquake_tech_response;_ylt=AnqHeQGpPQ_N1AQpvN9lFCZv24cA;_ylu=X3oDMTNscDQ3cWRwBGFzc2V0A2FwLzIwMTEwMzE1L3VzX3RlY19qYXBhbl9lYXJ0aHF1YWtlX3RlY2hfcmVzcG9uc2UEY2NvZGUDcmFuZG9tBGNwb3MDMQRwb3MDMQRzZW |

| May 6, 2011 - TDK Corporation |

| TDK Corporation expresses its heartfelt sympathy to the people and the community affected by the Great East Japan Earthquake. |

| The following list shows the status of TDK group sites in Tohoku and Kanto regions as of May 6. |

| TDK Micro Device Corporation will be fully operational on May 9. |

| However, there still remains the risk that some productions may be affected by the supply chain of materials. |

| -------------------------------------------------------------------------------- |

| (Reference) |

| The restoration situation of TDK group sites |

| TDK Group sites in Kanto District under the service by Tokyo Electric Power Company |

| JAPAN Sites Location Products Status as of May 6 |

| 1) TDK Corporation Narita Plant Narita-city, Chiba metal magnets The plant is in operation. |

| 2) TDK Corporation Kofu Plant Minami-Alps-city, Yamanashi thin-film devices, silicon devices The plant is in operation. |

| 3) TDK Corporation Technical Center Ichikawa-city, Chiba R&D base The R&D site is in operation. |

| 4) Media Technology Corporation Chuo-city, Yamanashi data storage tapes The plant is in operation. |

| 5)* TDK Micro Device Corporation Kitaibaraki-city, Ibaraki organic EL displays The plant will be fully operational on May 9. |

| TDK Group sites in Tohoku district under the service by Tohoku Electric Power Company |

| JAPAN Sites Location Products Status as of May 6 |

| 1) TDK Corporation Akita Plant Nikaho-city, Akita various electronic materials The plant is in operation. |

| 2) TDK-EPC Corporation Chokai Plant Nikaho-city, Akita ferrite cores The plant is in operation. |

| 3) TDK Corporation Kisakata Plant Nikaho-city, Akita various electronic components development The R&D site is in operation. |

| 4) TDK Corporation Inakura Plant Nikaho-city, Akita ferrite cores The plant is in operation. |

| 5) TDK Corporation Hirasawa Plant Nikaho-city, Akita R&D base The R&D site is in operation. |

| 6) TDK-MCC Coporation Akita Plant Nikaho-city, Akita multilayer ceramic chip capacitors speciality applications The plant is in operation. |

| 7) TDK-MCC Corporation Kitakami Plant Kitakami-city, Iwate high and large capacitance The plant is in operation. |

| 8) TDK-MCC Corporation Honjo Plant Yurihonjo-city, Akita general purpose products/high and large capacitance The plant is in operation. |

| 9) TDK-MCC Corporation Kisakata Plant Nikaho-city, Akita capacitors ultra high voltage The plant is in operation. |

| 10) TDK Ugo Corporation Ouchi Plant Yurihonjo-city, Akita coils, high-frequency components multilayer-types The plant is in operation. |

| 11) TDK Ugo Corporation Konoura Plant Nikaho-city, Akita high frequency The plant is in operation. |

| 12) TDK Ugo Corporation Yuzawa Plant Yuzawa-city, Akita multilayer-types The plant is in operation. |

| 13) TDK Ugo Corporation Iwaki Plant Yurihonjo-city, Akita multilayer-types The plant is in operation. |

| 14) TDK Yurihonjo Corporation Honjo Plant Yurihonjo-city, Akita power supplies The plant is in operation. |

| 15) TDK Yurihonjo Corporation Yashima Plant Yurihonjo-city, Akita sensors The plant is in operation. |

| 16) TDK Ujo Corporation Katagami-city, Akita capacitors middle and high voltage The plant is in operation. |

| 17) TDK Shonai Corporation Tsuruoka Plant Tsuruoka-city, Yamagata coils, transformers, power supplies, sensors signal-line inductors, power-line inductors, power supplies The plant is in operation. |

| 18) TDK Shonai Corporation Sakata Plant Sakata-city, Yamagata noise suppression components, thin-film devices, transformers The plant is in operation. |

| 19) TDK Shonai Corporation Yuza Plant Yuza-machi Akumi-gun, Yamagata sensors The plant is in operation. |

| 20) TDK-Lambda Corporation Nagaoka Technical Center Nagaoka-city, Niigata development and production of power supplies The plant is in operation. |

| Further information will be reported on this website. |

no reviews yet

Please Login to review.