306x Filetype XLSX File size 0.02 MB Source: excelwithwayne.com

Sheet 1: cycle service level

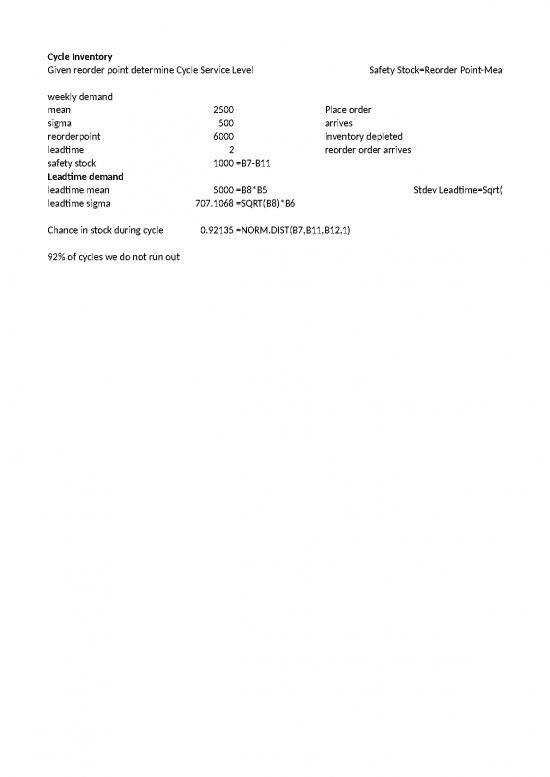

| Cycle Inventory | ||||||||

| Given reorder point determine Cycle Service Level | Safety Stock=Reorder Point-Mean Leadtime Demand | |||||||

| weekly demand | ||||||||

| mean | 2500 | Place order | ||||||

| sigma | 500 | arrives | variance for 2 weeks = 2*var for 1 week | |||||

| reorderpoint | 6000 | inventory depleted | stdev for2 weeks = sqrt(2)*stdev for 1 week | |||||

| leadtime | 2 | reorder order arrives | ||||||

| safety stock | 1000 | =B7-B11 | ||||||

| Leadtime demand | ||||||||

| leadtime mean | 5000 | =B8*B5 | Stdev Leadtime=Sqrt(N)*st dev for 1 week | |||||

| leadtime sigma | 707.106781186548 | =SQRT(B8)*B6 | ||||||

| Chance in stock during cycle | 0.921350396474857 | =NORM.DIST(B7,B11,B12,1) | ||||||

| 92% of cycles we do not run out |

| Reorder Point for | We want 90% Service Level | ||||

| Given Cycle Service Level | |||||

| determine reorder point and safety stock | Use NORM.INV function | ||||

| weekly demand | |||||

| mean | 2500 | ||||

| sigma | 500 | ||||

| reorderpoint | 5906.19380243682 | =NORM.INV(0.9,B11,B12) | ?? | ||

| leadtime | 2 | ||||

| safety stock | 906.193802436824 | ||||

| Leadtime demand | |||||

| leadtime mean | 5000 | ||||

| leadtime sigma | 707.106781186548 |

| Fill Rate | ||||

| Given reorder point | ||||

| determine fraction of all demand met on time | ||||

| weekly demand | ||||

| mean | 2500 | |||

| sigma | 500 | |||

| reorderpoint | 6000 | |||

| leadtime | 2 | |||

| safety stock | 1000 | Mean Shortage Per Cycle | ||

| Leadtime demand | SS*(1-Prob(Standard Normal <=SS/LeadtimeSigma)+LeadtimeSigma*StandardNormal Density(at SS/Leadtime Sigma) | |||

| leadtime mean | 5000 | |||

| leadtime sigma | 707.106781186548 | |||

| Order Quantity | 10000 | FROM EOQ | ||

| Expected Shortage per Cycle | 25.1272708300061 | =-B9*(1-NORM.DIST(B9/B12,0,1,1))+B12*NORM.DIST(B9/B12,0,1,0) | ||

| Fill Rate | 0.997487272916999 | =1-B14/B13 |

no reviews yet

Please Login to review.