354x Filetype XLSX File size 0.09 MB Source: www.zf.com

Sheet 1: QD83 Form F2.15

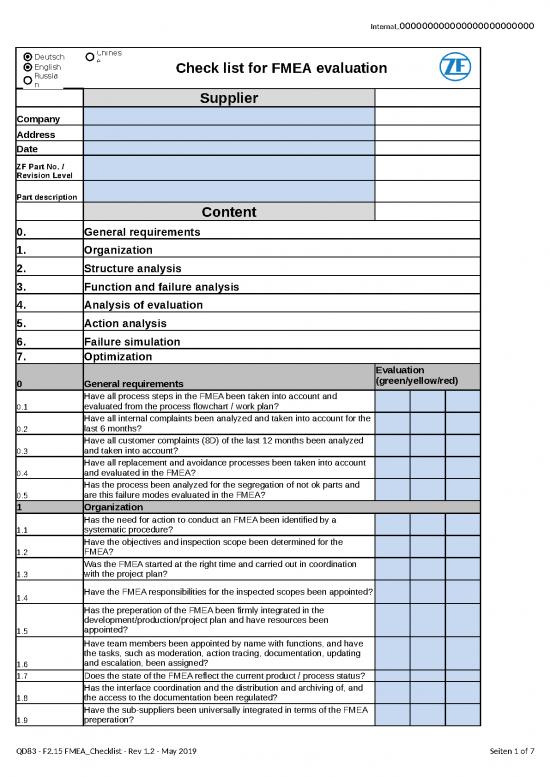

| Check list for FMEA evaluation | ||||

| Supplier | ||||

| Company | ||||

| Address | ||||

| Date | ||||

| ZF Part No. / Revision Level | ||||

| Part description | ||||

| Content | ||||

| 0. | General requirements | |||

| 1. | Organization | |||

| 2. | Structure analysis | |||

| 3. | Function and failure analysis | |||

| 4. | Analysis of evaluation | |||

| 5. | Action analysis | |||

| 6. | Failure simulation | |||

| 7. | Optimization | |||

| 0 | General requirements | Evaluation (green/yellow/red) | ||

| 0.1 | Have all process steps in the FMEA been taken into account and evaluated from the process flowchart / work plan? | |||

| 0.2 | Have all internal complaints been analyzed and taken into account for the last 6 months? | |||

| 0.3 | Have all customer complaints (8D) of the last 12 months been analyzed and taken into account? | |||

| 0.4 | Have all replacement and avoidance processes been taken into account and evaluated in the FMEA? | |||

| 0.5 | Has the process been analyzed for the segregation of not ok parts and are this failure modes evaluated in the FMEA? | |||

| 1 | Organization | |||

| 1.1 | Has the need for action to conduct an FMEA been identified by a systematic procedure? | |||

| 1.2 | Have the objectives and inspection scope been determined for the FMEA? | |||

| 1.3 | Was the FMEA started at the right time and carried out in coordination with the project plan? | |||

| 1.4 | Have the FMEA responsibilities for the inspected scopes been appointed? | |||

| 1.5 | Has the preperation of the FMEA been firmly integrated in the development/production/project plan and have resources been appointed? | |||

| 1.6 | Have team members been appointed by name with functions, and have the tasks, such as moderation, action tracing, documentation, updating and escalation, been assigned? | |||

| 1.7 | Does the state of the FMEA reflect the current product / process status? | |||

| 1.8 | Has the interface coordination and the distribution and archiving of, and the access to the documentation been regulated? | |||

| 1.9 | Have the sub-suppliers been universally integrated in terms of the FMEA preperation? | |||

| 1.10 | Has the type of documentation and the media been determined? | |||

| 1.11 | Have the symbols for the special characteristics of the organization been determined? | |||

| 2 | Structure analysis | |||

| 2.1 | Is a tracebale process description available, and are the requierements completely recorded/known? | |||

| 2.2 | Have the boundaries of the inspection been clearly determined within the structure? | |||

| 2.3 | Have interfaces been defined and coordinated? | |||

| 2.4 | Has the inspection scope in terms of depth of inspection been represented in a clearly comprehensible way? | |||

| 3 | Function and failure analysis | |||

| 3.1 | Have the functions been completely specified according to the objectives? | |||

| 3.2 | Have the functions been described in a way that can be verified and validated? | |||

| 3.3 | Have the failures been completely derived from the functions in accordance with the objectives? | |||

| 3.4 | Have the failures been significantly and comprehensively described? | |||

| 4 | Analysis of evaluation | |||

| 4.1 | Was the ZF ranking catalog used for the assessment of severity / occurance / detection according to DCF 17-02 "Special Characteristics"? | |||

| 4.2 | Is the effect of failures known or questioned in case of unclear assessment at ZF? | |||

| 5 | Action analysis | |||

| 5.1 | Have preventive and detection actions been specified for all failure causes, failures and/or their failure modes? | |||

| 5.2 | Have the actions been phrased comprehensively and clearly? | |||

| 5.3 | Is the status of all actions specified and current? | |||

| 5.4 | Have responsibilities and deadlines been specified for all actions? | |||

| 5.5 | Are actions executed that they can be implemented with regards to product development, process or service planning at the latest until the initial sampling? | |||

| 5.6 | Are there ranking standards for S, O and D available? | |||

| 5.7 | Are there distinctions between product- and process-specific assessment criteria? | |||

| 5.8 | Are the ranking standards agreed with ZF? | |||

| 5.9 | Are the ranking standards applied continiously in the FMEA? | |||

| 5.10 | Have O and D rankings been updated after impelementation of actions for all failure causes? | |||

| 5.11 | Have all actions been implemented and has the effectiveness been checked and documented? | |||

| 6 | Failure simulation | |||

| 6.1 | Has a failure simulation been carried out in the line to demonstrate the effectiveness of the actions? | |||

| 6.2 | Did an analysis of possible malfunctions, which are not yet contained in the FMEA, take place during the failure simulation? | |||

| 7 | ||||

| 7.1 | Were new actions decided in the case of unacceptable results? | |||

| 7.2 | Have the new actions been implemented and has their effectiveness been checked and documented? | |||

| 7.3 | Was the risk evaluation updated after implementation of new actions? | |||

| 7.4 | Have the FMEA results been communicated? | |||

| 7.5 | Has the FMEA documentation been archived? | |||

| 7.6 | Is the FMEA regularly updated in review? | |||

| 7.7 | Is the FMEA updated in case of complaints (required in the 8D report)? | |||

| Failed, containment actions and action plans necessary: (min. 15 X yellow, or 1 X red) | ||||

| Actions necessary: (max. 14 X yellow, and 0 X red) | ||||

| FMEA - self assessment / audit passed: (max. 7 X yellow, and 0 X red) | ||||

| Evaluation | The columns must be filled with "1". | 0 | 0 | 0 |

| Result | Audit passed | |||

| Date | Supplier, Dept. | Supplier Signature | ||

no reviews yet

Please Login to review.