300x Filetype XLS File size 0.36 MB Source: schnauber.com

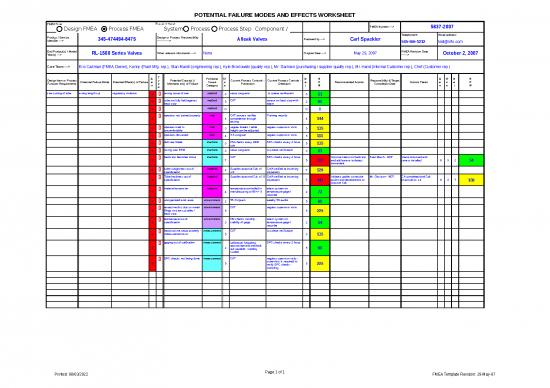

POTENTIAL FAILURE MODES AND EFFECTS WORKSHEET

FMEA Type Level of Detail

Design FMEA Process FMEA System Process Process Step Component / Part FMEA Number ---> 5637-2007

Telephone #: Email address:

Product / Service 345-474494-8475 Design or Process Responsibility Alleak Valves Prepared by ---> Carl Spackler

Identifier ---> -------------> 585-555-1212 test@info.com

End Product(s) / Model RL-1500 Series Valves Other relevant information ---> None Original Date ---> May 29, 2007 FMEA Revision Date October 2, 2007

Year(s) ---> ------>

Core Team ---> Eric Cartman (FMEA Owner), Kenny (Plant Mfg. rep.), Stan Marsh (engineering rep.), Kyle Brovlowski (quality rep.), Mr. Garrison (purchasing / supplier quality rep.), Mr. Hand (Internal Customer rep.), Chef (Customer rep.)

S T Fishbone O D R S O D R

Design Item or Process Potential Failure Mode Potential Effect(s) of Failure e y Potential Cause(s) / Cause c Current Process Controls - Current Process Controls - e P Recommended Actions Responsibility & Target Actions Taken e c e P

Function Requirements v p Mechanism(s) of Failure Category c Prevention Detection t N Completion Date v c t N

e

saw cutting of tube wrong length cut regulatory violation 9 I wrong setup of saw method 3 setup programs 1st piece verification 3 81

9 I tube not fully held against method 5 OJT sensor on back stop with 2 90

back stop alarm

9 I method 0 0 0

I operator not trained properly man OJT process verifies Training records

9 4 competence through 4 144

testing

9 I operator tired or man 3 regular breaks / table regular supervisor visits 5 135

uncomfortable height can be adjusted

9 I operator distracted man 4 5 S program regular supervisor visits 5 180

9 I dull saw blade machine 3 PM checks every 1000 SPC checks every 2 hours 5 135

cuts

9 I wrong saw RPM machine 3 setup programs 1st piece verification 3 81

I backstop becomes loose machine OJT SPC checks every 2 hours Improve clamp on backstop Stan Marsh - 9/07 clamp improved and

9 7 5 315 and add sensor to detect sensor installed 9 3 2 54

movement

9 I tube straightness out of material 2 Supplier approval Cpk of CofA verified at incoming 7 126

specification 1.8 inspection

I Tube hardness out of material Supplier approval Cpk of .8 CofA verified at incoming Initiate supplier corrective Mr. Garrison - 9/07 CA completed and Cpk

9 specification 7 inspection 7 441 action and development to improved to 1.4 9 3 7 189

improve Cpk

I material expansion material temperature controlled in alarm system on

9 4 manufacturing to 68 +/- 5 temperature gage / 2 72

recorder

9 I unorganized work area environment 2 5S Program weekly 5S audits 5 90

I excessive dirt, dust or metal environment OJT regular supervisor visits

9 filings on saw cut table / 5 5 225

back stop

I temperature out of environment PM checks monthly - alarm system on

9 specification 3 stability of gage temperature gage / 2 54

recorder

I backstop not setup properly - measurement OJT 1st piece verification

9 measurement error 5 3 135

I gaging out of calibration measurement calibration frequency SPC checks every 2 hours

appropriate and methods

9 2 are capable - stability 5 90

studies

I SPC checks not being done measurement OJT regular supervisor visits -

supervisor is required to

9 5 verify SPC checks - 5 225

sampling

Printed: 08/03/2022 Page 1 of 1 FMEA Template Revision: 29-May-07

no reviews yet

Please Login to review.