210x Filetype PDF File size 0.97 MB Source: epgp.inflibnet.ac.in

Module 15

Powder Diffraction

Learning Objectives

Introduction to Powder X-ray Diffracion

Bragg’s Law of Diffraction

Application of Powder XRD

Determination of an Unknown

Strengths and Limitations of X-ray Powder Diffraction

15.1 Introduction to Powder X-ray Diffraction

Powder X-ray diffraction (PXRD) is perhaps the most widely used analytical technique for

characterizing materials. As the name suggests, the sample is usually in a powdery form, consisting of

fine grains of single crystalline material to be studied. The technique is also used widely for studying

particles in liquid suspensions or polycrystalline solids (bulk or thin film materials).

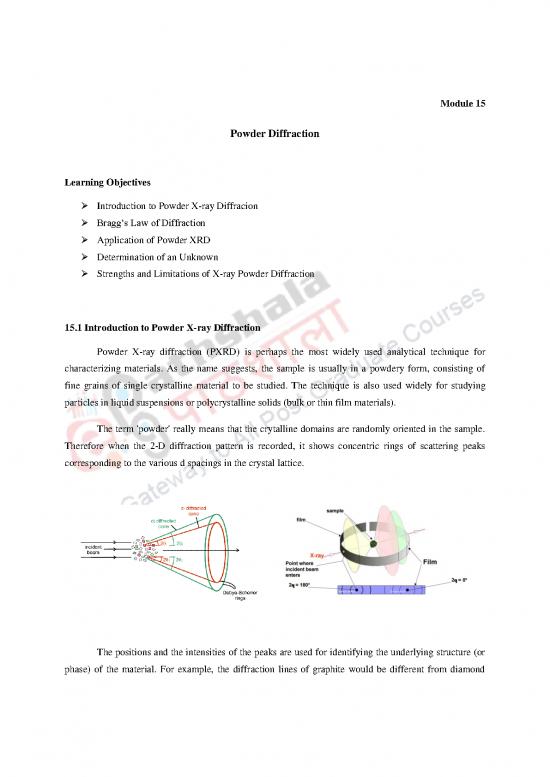

The term 'powder' really means that the crytalline domains are randomly oriented in the sample.

Therefore when the 2-D diffraction pattern is recorded, it shows concentric rings of scattering peaks

corresponding to the various d spacings in the crystal lattice.

The positions and the intensities of the peaks are used for identifying the underlying structure (or

phase) of the material. For example, the diffraction lines of graphite would be different from diamond

even though they both are made of carbon atoms. This phase identification is important because the

material properties are highly dependent on structure (just think of graphite and diamond).

Powder diffraction data can be collected using either reflection or transmission geometry, as

shown below.

Because the particles in the powder sample are randomly oriented, these two methods will yield

the same data.

A powder XRD scan typically represents a plot of scattering intensity v/s. the scattering angle 2θ

or the corresponding d-spacing. The peak positions, intensities, widths and shapes all provide important

information about the structure of the material.

The diffraction from ideal crystalline substances are characterized by well defined Bragg peaks in

X-ray diffraction. The crystalline substances have long range order. The amorphous substances do not

possess this long range order. So the diffraction from them do not show sharp Bragg peaks. In amorphous

phase, X-rays will be scattered in many directions leading to a large bump distributed in a wide range

(2θ) instead of high intensity narrower peaks.

Max von Laue, in 1912, discovered that crystalline substances act as three-dimensional

diffraction gratings for X-ray wavelengths similar to the spacing of planes in a crystal lattice. X-ray

diffraction is based on constructive interference of monochromatic X-rays and a crystalline sample. These

X-rays are generated by a cathode ray tube, filtered to produce monochromatic radiation, collimated to

concentrate, and directed toward the sample. In principle, X-ray diffractometers consist of three basic

elements: an X-ray tube, a sample holder, and an X-ray detector.

The X-ray wavelengths are characteristic of the target material (Cu, Fe, Mo, Cr). Filtering, by

foils or crystal monochrometers, is required to produce monochromatic X-rays needed for diffraction. Kα1

and K are sufficiently close in wavelength such that a weighted average of the two is used. Copper is the

α2

most common target material for single-crystal diffraction, with CuK radiation = 1.5418 Å. These X-rays

α

are collimated and directed onto the sample. As the sample and detector are rotated, the intensity of the

reflected X-rays is recorded. When the geometry of the incident X-rays impinging the sample satisfies the

Bragg Equation, constructive interference occurs and a peak in intensity occurs. A detector records and

processes this X-ray signal and converts the signal to a count rate which is then output to a device such as

a printer or computer monitor.

The interaction of the incident rays with the sample produces constructive interference (and a

diffracted ray) when conditions satisfy Bragg's Law. This law relates the wavelength of electromagnetic

radiation to the diffraction angle and the lattice spacing in a crystalline sample. These diffracted X-rays

are then detected, processed and counted. By scanning the sample through a range of 2θ angles, all

possible diffraction directions of the lattice should be attained due to the random orientation of the

powdered material. Conversion of the diffraction peaks to d-spacings allows identification of the material

because each material has a set of unique d-spacings. Typically, this is achieved by comparison of d-

spacings with standard reference patterns.

no reviews yet

Please Login to review.