212x Filetype PDF File size 0.49 MB Source: www.mcgill.ca

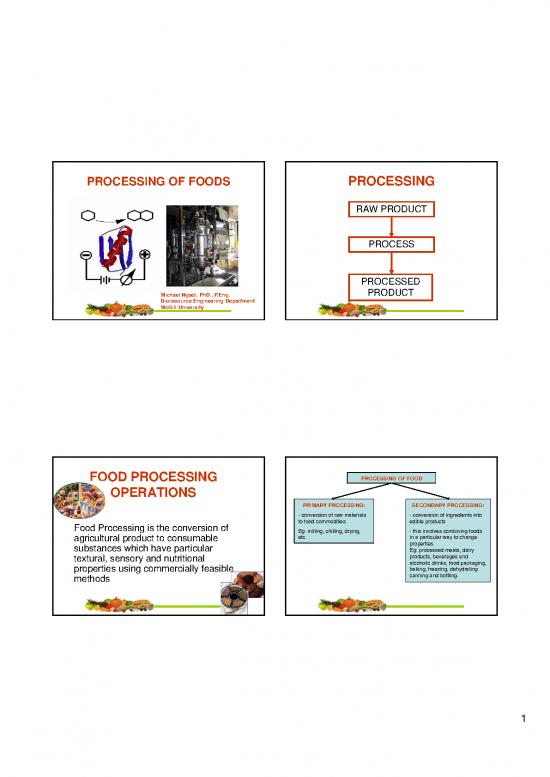

PROCESSING OF FOODS PROCESSING

RAW PRODUCT

PROCESS

PROCESSED

Michael Ngadi, PhD., P.Eng. PRODUCT

Bioresource Engineering Department

McGill University

FOOD PROCESSING PROCESSING OF FOOD

OPERATIONS

PRIMARY PROCESSING: SECONDARY PROCESSING:

- conversion of raw materials - conversion of ingredients into

Food Processing is the conversion of to food commodities edible products

Eg: milling, chilling, drying, - this involves combining foods

agricultural product to consumable etc. in a particular way to change

substances which have particular properties.

Eg: processed meats, dairy

textural, sensory and nutritional products, beverages and

alcoholic drinks, food packaging,

properties using commercially feasible baking, freezing, dehydrating

methods canning and bottling.

1

WHY PROCESS? FOOD PRODUCTS

to convert to edible products Products may be made by several processes. Interactions

between product and processes differ.

to preserve

Starch products Meat products

to extend availability and provide accessibility a. Bread a. Products from cattle

b. Cakes and biscuits b. Products from pigs

c. Pasta

to provide variety and choice d. Rice products Fish products

e. Corn products

Milk products

to provide convenience Oil products

a. Margarine Chocolate manufacture

to add value b. low fat spreads)

Drinks

TYPICAL FOOD PROCESSES UNIT OPERATIONS

Several steps are required to manufacture food products. Material Handling

The specific details of each may differ, but the basic Unique steps or Cleaning

principles are the same. Separating

Source ingredients Fillings added operations taken Size reduction

Delivery of ingredients Finish applied to prepare food Fluid Flow

Storage of ingredients Cooked products Mixing

(hoppers, bins, etc.) Heat transfer

Cooled Concentration

Weigh and mix

ingredients - formulation Stored These operations Drying

Mixture shaped or Packaged and labeled Forming

formed – extrusion, can stand alone Packaging

cutting, rolling, etc.

Distribution Controlling

2

TERMS PROCESS FLOWSHEETS

Process Design: the design of food processes Process flowsheets are graphical

and manufacturing methods, including process representations of the layout and flow of

flowsheets, design of processing and control equipment and materials in the plant.

equipment, and economic evaluation of the

process. PBD: Process block diagram

Plant Design: the design of whole processing PFD: Process flowsheet diagram

plant, including the processing/control equipment, PCD: Process control diagram

the utilities, the plant buildings, and the waste

treatment units. PID: Piping and instrumentation diagram

3

Energy accounting (process

block) diagram of tomato

paste manufacturing based

on an 8 hour shift

4

no reviews yet

Please Login to review.