236x Filetype PDF File size 1.37 MB Source: www.matec-conferences.org

MATEC Web of Conferences 149, 01015 (2018) https://doi.org/10.1051/matecconf/201814901015

CMSS-2017

Non-Destructive Testing for Building Diagnostics and Monitoring:

Experience Achieved with Case Studies

Ayşe Tavukçuoğlu

Middle East Technical University, Faculty of Architecture, Department of Architecture, Ankara, Turkey

Astract Building inspection on site, in other ords in-situ eaminations of uildings is a troulesome

ork that necessitates the use of nondestructive investigation DT techniues ne of the main

concerns of nondestructive testing studies is to improve in-situ use of DT techniues for diagnostic

and monitoring studies The uantitative infrared thermography

T and ultrasonic pulse velocity

U measurements have distinct importance in that regard The oint use of

T and ultrasonic

testing allos in-situ evaluation and monitoring of historical structures and contemporary ones in

relation to moisture, thermal, materials and structural failures hile the uildings themselves remain

intact For instances, those methods are useful for detection of visile and invisile cracks, thermal

ridges and damp ones in uilding materials, components and functional systems as ell as for

soundness assessment of materials and thermal performance assessment of uilding components n

addition, those methods are promising for moisture content analyses in materials and monitoring the

success of conservation treatments or interventions in structures The insitu DT studies for diagnostic

purposes should start ith the mapping of decay forms and scanning of uilding surfaces ith infrared

images uantitative analyses are shaped for data acuisition on site and at laoratory from

representative sound and prolem areas in structures or laoratory samples aoratory analyses are

needed to support insitu eaminations and to estalish the reference data for etter interpretation of in

situ data Advances in laoratory tests using

T and ultrasonic testing are guiding for insitu materials

investigations ased on measurale parameters The knoledge and eperience on

T and ultrasonic

testing are promising for the innovative studies on today’s materials technologies, uilding science and

conservationmaintenance practices uch studies demand a multidisciplinary approach that leads to

ring together knoledge on materials science and uilding science

ntroduction nfrared therograph and ultrasonic

Building inspection on site, in other ords in-situ testing in the context of uilding

eaminations of uildings is a troulesome ork that diagnostics and onitoring

necessitates the use of nondestructive investigation nsitu DT studies for diagnostic purposes start ith

DT techniues The uantitative infrared field oservations composed of mapping of decay forms

thermography

T and ultrasonic pulse velocity ith visual analyses and

scanning uantitative

U measurements have distinct importance in that analyses are shaped for data acuisition on site and at

regard ne of the main concerns of those non laoratory taken from representative sound and prolem

destructive testing methods is to improve their areas in structures or laoratory samples aoratory

uantitative use on site for diagnostic and monitoring analyses are needed to support insitu eaminations and

purposes The knoledge achieved on

T and to estalish the standardreference data for etter

ultrasonic testing is presented here, mostly ith a focus interpretation of the insitu data

on case studies conducted on historical materials and n order to enhance the accuracy of nondestructive

structures Those case studies are, in fact, research studies investigations, particularly the insitu ones, there is

shaped to develop insitu use of

T and ultrasonic necessity of using more than one DT testing method

testing methods for specific topics related to uilding and supporting the insitu investigation ith laoratory

inspection and monitoring as ell as to discover their tests Advances in laoratory tests using

T and

potentials and limitations in this regard ultrasonic testing are promising to give the hints of using

those methods on site for uantitative analyses, in other

© The Authors, published by EDP Sciences. This is an open access article distributed under the terms of the Creative Commons Attribution

License 4.0 (http://creativecommons.org/licenses/by/4.0/).

MATEC Web of Conferences 149, 01015 (2018) https://doi.org/10.1051/matecconf/201814901015

CMSS-2017

CMSS-2017

words, allow making in-situ examinations based on waves passing along a solid material through a certain

measurable parameters. distance between the transmitter and receiver. he

Infrared (IR) thermography is commonly used for measurable parameter of ultrasonic testing is the velocity

detection of building defects, such as thermal bridges, air of ultrasound waves propagating through the building

leakages or moist spots, particularly in the context of material. he ultrasonic pulse velocity () of a

energy conservation. It measures thermal radiation material is related with its physical and mechanical

emitted by the material and depicts the examined area as properties as well as the state of deterioration,

an image in colours corresponding to a predefined moisture water content and presence of discontinuity.

temperature scale. he application of a hot or cold source

ny discontinuity within a material or increase in

to a specific area results in the warming up or cooling porosity is expected to increase the travel time and,

down of the surface area under examination at varying conseuently, decrease the pulse velocity. he

rates. inal surface temperatures differ depending on the measurements can be made by positioning two

thermal properties, specifically thermal resistance and transducers (one transmitter and one receiver) on

thermal inertia characteristics, of the surface and sub- opposite faces (direct transmission mode) or on the same

surface layers. or instance, entrapped moisture in a surface (indirect transmission mode) of the material

porous material increases its thermal conductivity, sample.

therefore decreases its thermal resistance and creates a he measurements taken in direct transmission

kind of thermal bridge. uch a defect is visible in infrared mode ( ) are used for assessing the state of

IR

images as cooler areas. In addition, exposure of wet deterioration of a material and non-visible

surfaces to mild wind or sun increases the evaporation failure discontinuity at deeper layers, such as invisible

rate, therefore accelerates evaporative cooling. It means cracks. he measurements in indirect transmission

that heating the surfaces or wind effect may also enhance mode ( ) provides precise data on estimating

IIR

the visibility of moist areas in infrared images. the depth of a visible crack while investigating surfaces

he IR scanning is useful and time-saving for the in- in layers only accessible from one side. ifficulty in

situ check-up of the overall structure, especially with a access to mutually-perpendicular faces of a building

focus on visible and invisible materials defects, moisture component limits the applicability of direct

and thermal failures, and various materials use. owever, measurements on site. In such a case, there is necessity to

during the in-situ examinations the uantitative analyses establish the reference data obtained from control

of the representative areas are obligatory for the correct samples and correlate the data taken in direct and

interpretation of the problem areas detected in single IR indirect transmission modes. hat correlation makes it

images. hermal monitoring of the problem area by possible to interpret the in-situ data correctly in

means of seuential thermal imaging is a favourable reference to the control data.

techniue for uantitative analysis of the problem area. he combined use of infrared thermography and

his techniue allows taking infrared images in ultrasonic testing enhances the accuracy of the non-

seuences from the target area during the periods when destructive in-situ examination, especially the studies on

the target area is exposed to heating and then cooling soundness assessment.

good correlation is determined

conditions as well as producing differential thermal between the state of deterioration of stone and its thermal

images which show surface temperature differences inertia characteristics. he deteriorated stone samples

between the initial and the last IR images for heating or present lower values and faster warming up and

cooling period. ue to the changes in physical and cooling down rates than the sound ones.

thermal properties of the defect area, the impact of any ome research fields where IR and ultrasonic

failure can easily be followed in differential images. In testing can be useful are summaried as follows–

addition, the temperature evolution in time under heating – detection of visible and invisible defects failures in

and or cooling exposure conditions can be examined by materials and structures, such as deep and surface

the graphs showing changes in surface temperature as a cracks, detachments ,

function of suare root of time. he slope of the linear – detection of different materials use hidden behind the

regression presents the rate of warming up (R ) or the surfaces or buried within the section of building

rate of cooling down (R ) for each target area. hose components

rates are the measurable parameters related with the – assessment of the state-of-deterioration of building

thermal inertia characteristics of materials. hermal materials and their distribution in the structure ,

inertia characteristics of the problem area can also be

interpreted relatively by comparing the warming – failures in functional systems of historic structures,

up cooling rates of problem area in reference to the rates such as water supply and drainage systems -

of sound material (reference area). – assessment of thermal performance of structures as

In short, that investigation techniue is sensitive to well as thermal and moisture failures in structures ,

thermal characteristics of materials. ince thermal ,

characteristics are very related with the physical, – in-situ monitoring of the existing conditions before

physicomechanical and or mechanical properties of and after treatments, success of conservation

materials, changes in those properties can be monitored treatments in historic structures , , .

precisely by uantitative IR thermography. he advances in laboratory tests using IR are also

ltrasonic testing of building materials is based on promising to determine the thermal properties of

measuring the travel time (transit time) of ultrasonic materials and building walls while give the hints for in-

2

MATEC Web of Conferences 149, 01015 (2018) https://doi.org/10.1051/matecconf/201814901015

CMSS-2017

CMSS-2017

situ QIRT investigations to assess moisture content in 4000

y

t

i )

materials [3, 11, 14, 15]. oc s 3000

el /

V m

(

c 2000

oniues

as al1000

r V

t

l

3 Some case studies: prominent U 0

findings and advancements 56% 75% 90%

RH (%)

Here, some case studies are summarized under respective Parallel-To-Fiber Perpendicular-To-Fiber Direction

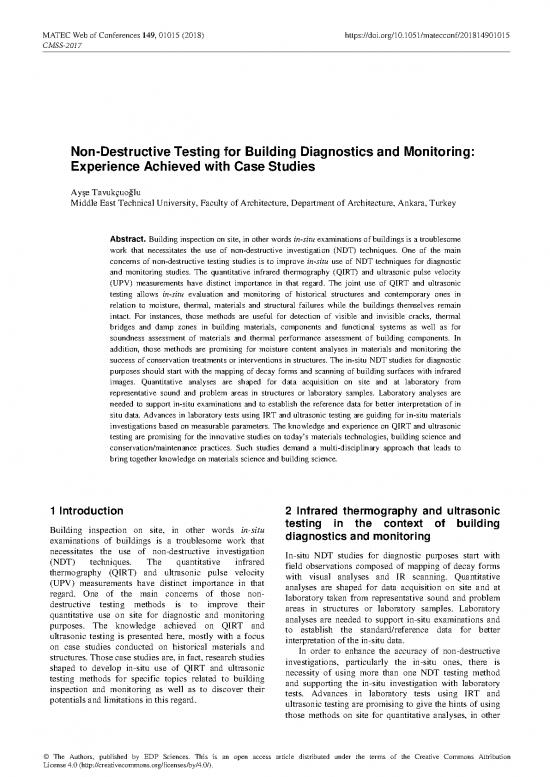

sueadings it a ocus on te prominent results o Fig. 1. anges in ultrasonic velocit values o timer samples

tose studies and guiding remars related it non due to te canges in moisture content [1].

destructive uilding inspection. Te

measurements eiit te anisotropic

eaviour o timer in relation to ier direction [11].

3.1 Soundness assessment of structural timber Te

IRT values parallel to ier direction are

elements on quantitative basis consideral iger tan up to 3 to 3.5 times iger te

ones perpendicular to ier direction. Te

IIRT

compreensive stud is needed or te insitu values are muc loer tan te

values it a

IRT

soundness assessment o structural timer elements tat ratio o .3 in average or te measurements taen in

involves parallel to ier direction. ased on tese relationsips,

– preliminary laboratory tests on control samples te

values measured on site rom timer

IIRT

deteriorated and nondeteriorated timer samples to suraces in parallel to ier direction can e used to

produce te reerence data on

and termal predict te

IRT values, tereore, te soundness o

caracteristics, timer.

– field measurements taen rom representative prolem In literature, te

values or sound timer

IRT

areas, and are given in te range o 1 to ms [1, ]. Te

– evaluation of in-situ data in reference to the control ultrasonic data or te sound timer control samples

data. measured in perpendiculartoier direction correspond

uc a stud as conducted on to tpes o structures it te data in literature it te

IRT value o

[11] 14 ms in average at 5 RH igure 1 [1,1]. Te

– Te 1t centur traditional timer dellings in same control samples ave te

value o

nara elonging to ttoman

eriod, namel aş IIRT

143 ms in average, measured in parallel to ier

House in te ton o aş and Istilal House in direction [1].

Istilal district Te timer post and eams orming en te timer deteriorates, its densit decreases

te timer rame all o traditional dellings ere and its arming upcooling rates increases. Te sound

eamined insitu

measurements taen in pine samples control samples ave te loest arming

direct and indirect transmission modes and upcooling rates and te igest densit, indicating teir

seuential IR imaging during cooling conditions. iger termal inertia. epending on severeness o

– slanane amii, 13t centur mosue, elonging to deterioration, te visualldeteriorated pine samples

elus

eriod Te timer pillars supporting te roo arm up or cool don aster tan te sound one control

and timer ceiling o te structure ere eamined sample in te range o 1. and 1.. easuring te

insitu

measurements taen in direct canges in arming up or cooling don rates o timer

transmission mode and IR scanning. samples allos assessing teir state o deterioration in

Reerence data estalised te laorator analses comparison to sound reerence samples.

on control timer samples ere used or te precise

interpretation o insitu data.

3.1.2 Evaluation of in-situ data with respect to

reference data

3.1.1 The reference data achieved at laboratory

ome timer eams and posts in timer ramed ouses

Te old and ne pine samples, visualldeteriorated and ad

IIRT values in te range o 133 to 11 ms

sound ones, collected rom te structures ere eamined taen in parallel to ier direction [1]. valuation o in

in terms o densit, euilirium moisture content at situ

data it respect to te reerence data as

various RH conditions,

taen in direct and indirect son tat tose timer elements are still sound. Tat

transmission modes and arming up and cooling rates. result as also conirmed it insitu

IRT

Te

values o timer samples decrease at ig measurements taen in perpendicular to ier direction

moisture conditions [1]. Tis means tat erever cross arrangements or te transducers could e

psicomecanical properties o timer elements eaen made. Tose

measurements in te range o

IRT

en te get et igure 1. Te relationsip eteen 141 ms are in agreement it values given or te

te

values and relative umidit conditions so sound timer material in literature [1, ].

artial

tat microclimatic data is an important input or correct deteriorations on some parts o timer posts and eams

interpretation o te

data, particularl or te insitu could e detected it

values elo te

IIRT

ultrasonic investigations. acceptale range. In sort, insitu

and

IIRT

IRT measurements ave assured te soundness o

3

MATEC Web of Conferences 149, 01015 (2018) https://doi.org/10.1051/matecconf/201814901015

CMSS-2017

CMSS-2017

structural timber elements in some parts and extensive – The deeper cracs at masonry wall, on the other hand,

deterioration in other parts of the structures under presented noticeably slower warming up and cooling

examination. down rates than the sound stone surfaces.

The sound timber elements present even surface – The deepest cracs allowing air leaage through the

temperature distribution in differential IR images while wall section had the coldest initial surface temperature

the deteriorated ones show heterogeneous temperature and slightly cooled down during the heating period

distribution (figure 2). In addition, the cooling rates of due to the accelerated evaporative cooling in the crac

deteriorated and severely deteriorated timber postbeam cavity.

were found to be . and 2. times faster than the

cooling rate of the sound postbeam, respectively . 1000 Depth of discontinuity at jointing = 86mm

This meant that thermal inertia of deteriorated timber s 800

µ y = 8.9674x - 928.75

,

e 600

decreases due to decrease in density and increase in m y = 1.2338x y = 3.4017x - 106.47

t ti

si 400

n

porosity. a y = 0.975x y = 3.6011x - 155.78

r

T 200

0.0dC 0

0

0 30 60 90 120 150 180 210 240 270 300

-1

-2 Distance, mm

-3 Discontinuity through the jointing at the depth of 86mm

Proper adhesion through the jointing

-4

-5 Fig. 3. The slope of regression lines for the tuff stone followed

-6 by proper ointing without any discontinuity (lines in green) and

-7

-7.0dC the change in the regression slope corresponding to the depth of

Fig. 2. artial view from the timber frame wall of İstilal ouse discontinuity at ointing (lines in orange) .

(at the left) the differential IR image showing the temperature

difference between the initial and the last IR images during the 1.5 1.321.44

1.13

cooling period of

seconds . 1.2 1.06

0.9

0.6 0.41

The values taen in perpendicular to fiber 0.40 0.29 0.31

IRT 0.3 0.10

direction from the timber pillars in slanhane amii were 0.0 -0.22

measured in the range of

to ms , . Those -0.3 Superficial Plaster Fracture at Crack on red Deepest

crack detachment jointing - tuff - crack with air

data falling into the reference values obtained neighbouring d=88mm d=147mm flow

IRT plaster

for sound timber show that the timber pillars of the detachment

ratio of warming up rates - defect to sound

mosue are still sound. ratio of cooling down rates - defect to sound

Fig. 4. The ratios of the R (or R ) of cracdefect to the R (or

R ) of soundreference stone surface .

3.2 Crack depth assessment in stone masonry

n insitu examination on structural cracs with a focus 3.3 Identification of emergency areas that

on depth assessment was conducted on a th century needed conservation treatments and their

ttoman mosue in nara, enabi hmet aşa amii monitoring

. This stone masonry structure with a bric upper

structure suffers from serious cracs observed at its walls comprehensive research involved IRT and ultrasonic

and dome due to the differential settlement of the clayey testing supported by the maps of visual decay forms and

ground following the extremely dry seasons of recent laboratory tests was conducted on emrut ağ

years 2, 22. onument, which is an archaeological site located in

y the study, a nondestructive investigation method eastern Turey in the province of ahta dıyaman and

was developed for the estimation of crac depth in a positioned at the top of emrut ağ at 2

m altitude.

structure by the combined use of IRT and ultrasonic The site is in the list of orld ultural eritage since

testing . The depths of cracs in accessible areas were . The study was focused on the insitu examination

predicted by uantitative analyses of IIRT data of the limestone and sandstone statues in emrut ağ

taen parallel to the stone surfaces (figure ). The thermal onument to assess their state of deterioration and to

inertia characteristics of those cracs with nown depths determine the target areas that needed urgent

were defined by uantitative analyses of surface conservation treatments 2, .

temperature data. The cracs which are not accessible for The reference data on and thermal inertia

ultrasonic testing were then able to be monitored by characteristics of sound and deteriorated limestone and

thermographic analyses to identify whether they are deep sandstone samples were produced (figure ). The

or superficial cracs. relationship between the state of deterioration of stone

The superficial and deep cracs have different thermal surfaces and their thermal inertia characteristics was then

responses to exposed conditions which made them easily used for the assessment of problem areas on statues

distinguishable by IRT analyses (figure ). or surfaces. The deteriorated stone samples present lower

instances values and faster warming up (R) and cooling

– The superficial cracs associating withneighbouring down (R) rates than the sound ones. In other words, the

plaster detachments had thermal response similar to weaening in physicomechanical properties causes the

detached surfaces, having faster warming up and thermal inertia of the deteriorated stone samples to

cooling down rates than the sound stone surfaces. decrease.

4

no reviews yet

Please Login to review.