220x Filetype PDF File size 0.47 MB Source: www.macsauto.co.za

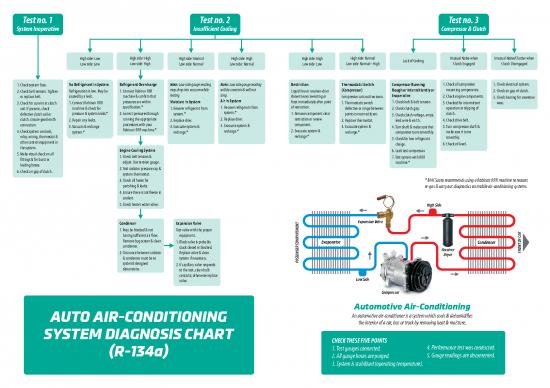

Test no. 1 Test no. 2 Test no. 3

SystemInoperative Insufficient Cooling Compressor & Clutch

High side: Low High side: High High side: Normal High side: High High side: High High side: Normal Lack of Cooling Unusual Noise when Unusual Noise/Chatter when

Low side: Low Low side: High Low side: Normal Low side: Normal Low side: Low Low side: Normal~High Clutch Engaged Clutch Disengaged

1. Check system fuse. No Refrigerant in System RefrigerantOvercharge Note:Low side gauge reading Note:Low side gauge reading Restriction Thermostatic Switch Compressor Running 1. Check all compressor 1. Check electrical system.

2. Check belt tension.Tighten Refrigeration is low. May be 1. Connect RobinarRRR may drop into vacuum while will be constant & will not Liquid line or receiver-drier (Compressor) Rough or Intermittently or mounting components. 2. Check air gap of clutch.

or replace belt. caused byaleak. machine & confirm that testing. drop. shows heavy sweating or Compressor cuts out too soon. Inoperative 2. Check engine components. 3. Check bearing for excessive

3. Check for current at clutch 1. Connect Robinair RRR pressures are within Moisture inSystem Air in System frost immediately after point 1.Thermostatic switch 1. Check belt & belt tension. 3. Checked for intermittent wear.

coil. If present, check machine & check for specification.* 1. Recover refrigerant from 1. Recover refrigerant from of restriction. defective or range between 2. Check clutch gap. operation or slipping of

defective clutch coil or pressure & system leaks.* 2. Correct pressures through system.* system.* 1. Remove component clear points is incorrectly set. 3. Check clutch voltage, amps, clutch.

clutch. Ensure good earth 2. Repair any leaks. running the appropriate 2. Replace drier. 2. Replace drier. restriction or renew 2. Replace thermostat. lead wire &earth. 4. Check drive belt.

connection. 3.Vacuum & recharge procedures with your 3. Evacuate system & 3. Evacuate system & component. 3. Evacuate system & 4.Turn shaft & make sure that 5.Turn compressor shaft&

4. Check system controls, system.* Robinair RRRmachine.* recharge.* recharge.* 2. Evacuate system & recharge.* compressor turns smoothly. make sure it turns

relay, wiring, thermostat & recharge.* 5. Check for low refrigerant smoothly.

other control equipment in charge. 6. Check oil level.

the system. Engine Cooling System 6. Leak test compressor.

5. Make visual check on all 1. Check belt tension & 7.Test system with RRR

fittings & for burst or adjust. Use tension gauge. machine.*

leaking hoses.

6. Check air gap of clutch. 2.Test radiator pressure cap &

system thermostat.

3. Check all hoses for *MACSauto recommends using a RobinairRRRmachine to recover,

perishing & leaks. re-gas & carry out diagnostics on mobileair-conditioningsystems.

4. Ensure there is antifreeze in

coolant.

5. Check heater water valve. High Side

Condenser ExpansionValve Expansion Valve

1. May be blocked & not Test valve with the proper TMENT R

having sufficient air flow. equipment. AR A

Remove bug screen & clean 1. Block valve is probably OMP Evaporator Condenser

condenser. stuck closed or blocked.

2. Clearance between radiator Replace valve & clean Receiver FRONT OF C

Dryer

& condenser must be to system if necessary. SSENGER C

A

system’s designed P

2. If capillary valve responds

dimensions. to the test, clean bulb

contacts; otherwise replace

valve. Low Side

Compressor

Automotive Air-Conditioning

AUTO AIR-CONDITIONING An automotive air-conditioner is a system which cools & dehumidifies

the interior of a car, bus or truck by removing heat & moisture.

SYSTEM DIAGNOSISCHART

CHECKTHESE FIVE POINTS

(R-134a) 1. Test gauges connected. 4. Performance test was conducted.

2. All gauge hoses are purged. 5. Gauge readings are documented.

3. System is stabilised (operating temperature).

no reviews yet

Please Login to review.