203x Filetype PPT File size 1.38 MB Source: users.fs.cvut.cz

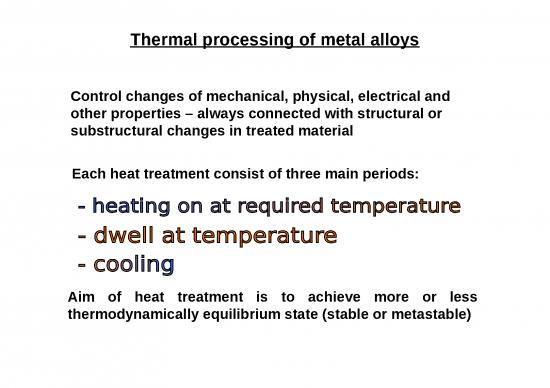

Thermal processing of metal alloys

Heat treatment (temperature effect)

•

annealing (to get more stable state)

reduce internal stress, reach softer and ductile structure, …

•

hardening (to get metastable state)

increases strength, hardness, wear resistance, …

Thermomechanical treatment

(effect of temperature and deformation)

control of final structure and mechanical properties

Chemical heat treatment

(effect of temperature and changes of the chemical composition)

to get different properties of surface layer as in core of the piece

– higher hardness, better wear or corrosion resistance, …

Heat treatment of steels

Annealing

Lower critical temperature (without transformation)

•

Process (recrystallization) annealing

•

Stress relief annealing

•

Spheroidizing

Upper critical temperature (partial or whole transformation)

•

Normalizing

•

Homogenization

Process (recrystallization) annealing

550 – 700 °C, 1- 5 hours, cooling in air

To change the structure and properties of cold worked (strain

hardened) steel.

Recovery and recrystallization processes occur.

Softening, increase ductility and uniform fine grain structure is

achieved.

Stress relief annealing

400 – 650 °C, 2 - 10 hours, very slow cooling in furnace

Reduce internal residual stresses (after machining, heat

treatment, …)

Spheroidizing (soft annealing)

700 °C, 5 – 25 hours, slow cooling to 600 °C in furnace, then

cooling may continue in air.

Spheroidite structure is developed

Used to improve machineability and toughness.

Normalizing

50 – 80 °C above upper critical temperature (phase diagram),

cooling in air.

Austenitization of the steel is required and cooling in accordance

with CCT diagram to get uniform and fine grain structure.

Full annealing

over A and A with furnace cooling.

3 1

Homogenization

1100 - 1200 °C (200 °C under solidus!)

To reduce structure and chemical composition inhomogeneities

after casting.

no reviews yet

Please Login to review.