211x Filetype PPT File size 0.16 MB Source: elsmar.com

Phases 2 and 3

• Phase 2 - Design • Phase 3 - Process

– Objectives – Objectives

• Develop design features and • Develop a comprehensive and

characteristics effective manufacturing system

• Critically review engineering • Ensure that the manufacturing

requirements systems meet customer

requirements

• Assess potential manufacturing –

problems Outputs

– Outputs by Design

Responsibility Activity

– Outputs by Advanced Product

Quality Planning Team

Marketing & Communications

Links Between the Tools

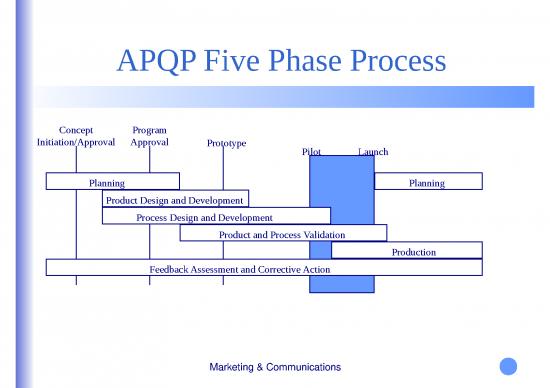

Contract Review Determine Customer Expectations and Plan for Quality Phase I

Program Plan

DFMEA Identify Key Characteristics Phase II

DVP&R and Team Feasibility Determine Risk and Feasibility Phase II

Commitment

Produce Process Phase III

Flow Diagrams Associate Characteristics with Process Steps and Identify Key Characteristics

Conduct Process Expose Sources of Variation and Finalize Key Characteristics Phase III

FMEA

Develop Determine Methods to Improve Process and Control Variation Phase III

Control Plan

Work Instruction Implement Control Plan and Standardize the Process Phase III

Development

Product and Ensure Customer Expectations are Met Phase IV

Process Validation

Ensure Continuous Exercise Management Oversight Phase V

Improvement

Marketing & Communications

How a PFMEA Works

• Where does the data for the PFMEA come

from?

• What types of people are a part of the

PFMEA team?

• What types of activities should we spend a

lot of time on?

Marketing & Communications

Link Between the Documents

Process Flow PFMEA Control Plan

Operation Number

Product/Process

Characteristic

Incoming Sources Variation Class

of Variation

Work Instructions

Marketing & Communications

APQP Links to PFMEA

PFMEA Control Plan Work Instructions

Change in detection

Change in occurence or

Change in severity

or

or or

Design Change Other Action

Marketing & Communications

no reviews yet

Please Login to review.