282x Filetype XLS File size 0.40 MB Source: www.southadams.k12.in.us

Sheet 1: METRIC CONVERSIONS

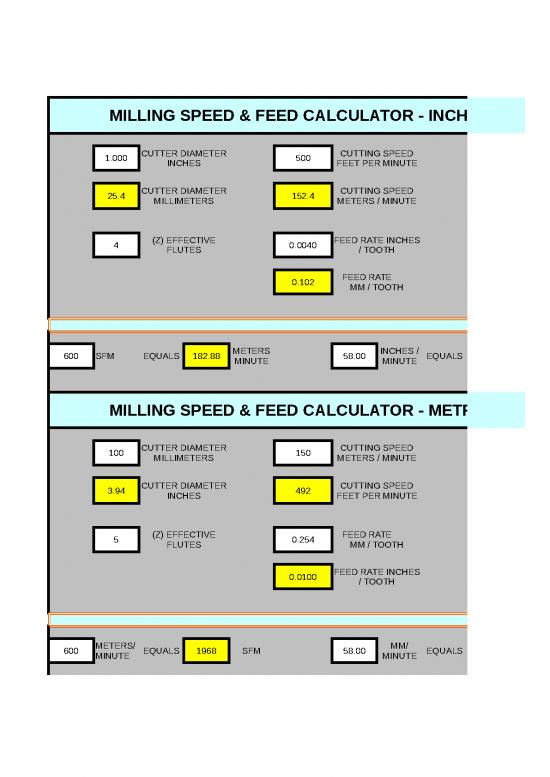

| MILLING SPEED & FEED CALCULATOR - INCH to METRIC | |||||||||||

| 1.000 | CUTTER DIAMETER INCHES | 500 | CUTTING SPEED FEET PER MINUTE | ||||||||

| 1910 | RPM | ||||||||||

| 25.4 | CUTTER DIAMETER MILLIMETERS | 152.4 | CUTTING SPEED METERS / MINUTE | ||||||||

| 4 | (Z) EFFECTIVE FLUTES | 0.0040 | FEED RATE INCHES / TOOTH | 30.56 | TABLE FEED INCHES / MIN. | ||||||

| 0.102 | FEED RATE MM / TOOTH | 776.2 | TABLE FEED MM / MIN. | ||||||||

| 600 | SFM | EQUALS | 182.88 | METERS MINUTE | 58.00 | INCHES / MINUTE | EQUALS | 1473.2 | MM / MINUTE | ||

| MILLING SPEED & FEED CALCULATOR - METRIC to INCH | |||||||||||

| 100 | CUTTER DIAMETER MILLIMETERS | 150 | CUTTING SPEED METERS / MINUTE | ||||||||

| 477 | RPM | ||||||||||

| 3.94 | CUTTER DIAMETER INCHES | 492 | CUTTING SPEED FEET PER MINUTE | ||||||||

| 5 | (Z) EFFECTIVE FLUTES | 0.254 | FEED RATE MM / TOOTH | 606.4 | TABLE FEED MM / MIN. | ||||||

| 0.0100 | FEED RATE INCHES / TOOTH | 23.87 | TABLE FEED INCHES / MIN. | ||||||||

| 600 | METERS/MINUTE | EQUALS | 1968 | SFM | 58.00 | MM/ MINUTE | EQUALS | 2.283 | INCHES/ MINUTE | ||

| TURNING SPEED & FEED CALCULATOR - INCH TO METRIC | |||||||||||

| 1.0000 | PART DIAMETER INCHES | 100 | CUTTING SPEED FEET PER MINUTE | ||||||||

| 25.40 | PART DIAMETER MILLIMETERS | 30.48 | CUTTING SPEED METERS/MINUTE | 382 | RPM | ||||||

| 0.005 | FEED RATE INCH/REV (IPR) | 0.127 | FEED RATE MM/REV (MMPR) | ||||||||

| 0.03 | DEPTH OF CUT INCHES (DOC) | 0.762 | DEPTH OF CUT/MM (DOC) | ||||||||

| 300 | SFM | EQUALS | 91.44 | METERS MINUTE | 70.00 | INCHES / MINUTE | EQUALS | 1778.00 | MM / MINUTE | ||

| TURNING SPEED & FEED CALCULATOR - METRIC TO INCH | |||||||||||

| 101.60 | PART DIAMETER MILLIMETERS | 100 | CUTTING SPEED METERS/MINUTE | ||||||||

| 4.0000 | PART DIAMETER INCHES | 328.1 | CUTTING SPEED FEET PER MINUTE | 313 | RPM | ||||||

| 0.10 | FEED RATE MM/REV (MMPR) | 0.0039 | FEED RATE INCHES/REV (IPR) | ||||||||

| 0.03 | DEPTH OF CUT/MM (DOC) | 0.0012 | DEPTH OF CUT INCHES (DOC) | ||||||||

| 600 | METERS/MINUTE | EQUALS | 1968 | SFM | 58.00 | MM/ MINUTE | EQUALS | 2.283 | INCHES/ MINUTE | ||

| CIRCLE INTERPOLATION MILLING CALCULATOR | |||||||||||

| NOTE: During internal circle interpolations, the outside diameter of a milling cutter advances faster than the centerline of the tool. This will produce a thicker chip than the calculated feed rate. (IPT) During external circle interpolations, the outside diameter of a milling cutter will advance slower than the centerline of the tool. This will produce a thinner chip than the calculated feed rate. (IPT) When less than 1/2 of the diameter of the tool is engaged (radial) with the workpiece, there will also be radial chip thinning effects. This calculator solves for both effects. Enter the cutter diameter, radial width of cut (WOC), the internal or external circle diameter (diameter being produced, not starting diameter) and the desired chip load per tooth. (IPT) The calculator will give you the "adjusted" feed rate (IPT) to maintain the desired chip thickness. | |||||||||||

| INTERNAL APPLICATIONS | |||||||||||

| 0.500 | Cutter Diameter | 6.100 | Circle Diameter (after the cut) | ||||||||

| 0.300 | Radial Width of Cut (WOC) | 0.0020 | Desired Chip Load (IPT) | ||||||||

| 0.0018 | Adjusted Chip Load (IPT) | ||||||||||

| NOTE: If the operation is not a full circle interpolation, simply input into the "Circle Diameter" data cell what the theoretical circle size would be. EXAMPLE: A 1.00 inch diameter end mill cuts an internal 90 degree corner that has a .625 inch radius. The circle diameter is the radius X 2, or 1.250 inches. For ID operations the radius of the cutting tool must always be equal to or smaller than the radius to be interpolated. Whenever practical, try to have the tool diameter be less than or equal to about 1/3 of the diameter to be interpolated | |||||||||||

| EXTERNAL APPLICATIONS | |||||||||||

| 1.000 | Cutter Diameter | 4.000 | Circle Diameter (after the cut) | ||||||||

| 0.500 | Radial Width of Cut (WOC) | 0.0050 | Desired Chip Load (IPT) | ||||||||

| 0.0063 | Adjusted Chip Load (IPT) | ||||||||||

| NOTE: If the operation is not a full circle interpolation, simply input into the "Circle Diameter" data cell what the theoretical circle size would be. EXAMPLE: A 1.00 inch diameter end mill cuts a 45 degree corner that has a 4.00 inch radius. The circle diameter is the radius X 2, or 8.00 inches. Whenever practical, it is a good idea to have the tool diameter greater than about 1/2 of the radial width of cut on external interpolations. | |||||||||||

| Radial Chip Thinning Calculator | |||||||||||

| NOTE: For use when less than 1/2 of the diameter of milling cutter is engaged in the width of cut (WOC) and for all slotting type cutters. The chip thickness produced with less than 1/2 of the diameter in radial contact will be thinner than calculated feed per tooth due to radial chip thinning. Enter the "desired chip load" (IPT) into the calculator. The calculator will give the "adjusted" feed rate (IPT) to produce the desired chip thickness. | |||||||||||

| 1.0000 | TOOL DIAMETER | 0.0250 | RADIAL WIDTH OF CUT (WOC) | ||||||||

| 0.0050 | DESIRED CHIP LOAD (IPT) | 0.0160 | ADJUSTED CHIP LOAD (IPT) | ||||||||

| 0.0016 | Actual maximum chip thickness if Radial Chip Thinning Calculation is not used. | 0.3122 | Radial Chip Thinning Factor | ||||||||

| The output from these calculations are correct for linear machining (straight line) applications. During circle interpolations and other milling applications where a radius is generated, other factors must be accounted for. Refer to the Circle Interpolation Calculator. | |||||||||||

no reviews yet

Please Login to review.