|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

INCREMENTAL COST TO UPGRADE TO NEW TECHNOLOGY PACKAGE |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

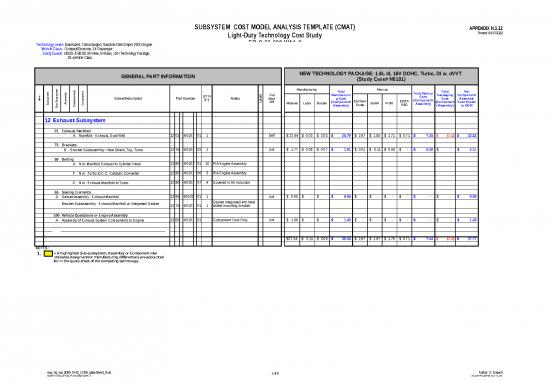

NEW TECHNOLOGY PACKAGE: 1.6L I4, 16V DOHC, DI, Turbo w. dVVT

(Study Case# N0101) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| GENERAL PART INFORMATION |

|

NEW TECHNOLOGY PACKAGE: 1.6L I4, 16V DOHC, Turbo, DI w. dVVT

(Study Case# N0101) |

|

BASE TECHNOLOGY PACKAGE: 2.4L I4, 16V DOHC, NA, PFI w. dVVT

(Study Case# B0101) |

|

BASE TECHNOLOGY PACKAGE: 2.4L I4, 16V DOHC, NA w. dVVT

(Study Case# B0101) |

| Item |

Subsystem |

Sub-Subsystem |

Assembly |

Subassembly |

Component |

Name/Description |

Part Number |

QTY/P.T |

Notes |

Level |

Full

Mod.

Diff. |

|

Manufacturing |

Total Manufacturing Cost (Component/ Assembly) |

Markup |

Total Markup Cost (Component/ Assembly) |

Total Packaging Cost (Component/ Assembly) |

Net Component/ Assembly Cost Impact to OEM |

|

Manufacturing |

Total Manufacturing Cost (Component/ Assembly) |

Markup |

Total Markup Cost (Component/ Assembly) |

Total Packaging Cost (Component/ Assembly) |

Net Component/ Assembly Cost Impact to OEM |

|

Manufacturing |

Total Manufacturing Cost (Component/ Assembly) |

Markup |

Total Markup Cost (Component/ Assembly) |

Total Packaging Cost (Component/ Assembly) |

Net Component/ Assembly Cost Impact to OEM |

|

Material |

Labor |

Burden |

End Item Scrap |

SG&A |

Profit |

ED&T-R&D |

|

Material |

Labor |

Burden |

End Item Scrap |

SG&A |

Profit |

ED&T-R&D |

|

Material |

Labor |

Burden |

End Item Scrap |

SG&A |

Profit |

ED&T-R&D |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

12 |

Exhaust Subsystem |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

01 |

Exhaust Manifold |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

Manifold - Exhaust, Dual Wall |

|

|

|

|

12 |

01 |

- |

N0101 |

- |

01 |

1 |

|

|

Diff. |

|

$22.64 |

$0.03 |

$3.03 |

$25.70 |

$2.97 |

$1.85 |

$1.71 |

$0.71 |

$7.25 |

$(0.12) |

$32.82 |

|

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

|

$22.64 |

$0.03 |

$3.03 |

$25.70 |

$2.97 |

$1.85 |

$1.71 |

$0.71 |

$7.25 |

$(0.12) |

$32.82 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

75 |

Brackets |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

Bracket Subassembly- Heat Shield, Top, Turbo |

|

|

|

|

|

12 |

75 |

- |

N0101 |

- |

02 |

1 |

|

|

Diff. |

|

$1.77 |

$0.08 |

$0.07 |

$1.91 |

$0.01 |

$0.11 |

$0.08 |

$- |

$0.20 |

$- |

$2.11 |

|

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

|

$1.77 |

$0.08 |

$0.07 |

$1.91 |

$0.01 |

$0.11 |

$0.08 |

$- |

$0.20 |

$- |

$2.11 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

80 |

Bolting |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

Nut- Manifold Exhaust to Cylinder Head |

|

|

|

|

12 |

80 |

- |

N0101 |

- |

01 |

10 |

PIA Engine Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F |

Nut - Turbo to C.C. Catalytic Converter |

|

|

|

|

12 |

80 |

- |

N0101 |

- |

06 |

3 |

PIA Engine Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

Nut - Exhaust Manifold to Turbo |

|

|

|

|

12 |

80 |

- |

N0101 |

- |

07 |

4 |

Covered in Air Induction |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

85 |

Sealing Elements |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

Gasket Assembly - Exhaust Manifold |

|

|

|

|

|

|

12 |

85 |

- |

B0101 |

- |

01 |

1 |

|

|

Diff. |

|

$0.95 |

$- |

$- |

$0.95 |

$- |

$- |

$- |

$- |

$- |

$- |

$0.95 |

|

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

|

$0.95 |

$- |

$- |

$0.95 |

$- |

$- |

$- |

$- |

$- |

$- |

$0.95 |

|

|

|

Bracket Subassembly - Exhaust Manifold w. Integrated Gasket |

|

|

|

|

|

|

12 |

75 |

- |

N0101 |

- |

01 |

1 |

Gasket integrated into heat shield mounting bracket. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

100 |

Vehicle Operations or Engine Assembly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A |

Assembly of Exhaust System Components to Engine |

|

|

|

|

|

|

12 |

00 |

- |

N0101 |

- |

01 |

|

Component Cost Only |

|

Diff. |

|

$1.89 |

$- |

$- |

$1.89 |

$- |

$- |

$- |

$- |

$- |

$- |

$1.89 |

|

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

|

$1.89 |

$- |

$- |

$1.89 |

$- |

$- |

$- |

$- |

$- |

$- |

$1.89 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$27.24 |

$0.11 |

$3.09 |

$30.45 |

$2.97 |

$1.97 |

$1.79 |

$0.71 |

$7.44 |

$(0.12) |

$37.77 |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$- |

$27.24 |

$0.11 |

$3.09 |

$30.45 |

$2.97 |

$1.97 |

$1.79 |

$0.71 |

$7.44 |

$(0.12) |

$37.77 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| NOTES: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Technology Level: |

Downsized, Turbocharged, Gasoline Direct Inject (GDI) Engine/ Compact Vehicle Class |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

OEM Operating Pattern (Weeks/Year): |

47 |

|

|

|

|

|

OEM Plant Location: |

North America |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vehicle Class: |

Compact/Economy 2-4 Passenger |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Annual Engine Volume (CPV): |

450,000 |

|

|

|

|

|

Supplier Plant Location: |

North America |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Study Case#: |

N0101 (N = New, 01 = Technology Package, 01 = Vehicle Class ) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Components per Engine: |

1 |

|

|

|

|

|

OEM/T1 Classification: |

T1 Moderate Assembly Complexity |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

257.142857142857 |

|

|

|

|

|

|

|

|

|

|

|

|

|

System Description: |

2007 Mini Cooper S. 1.6L I4, 16V DOHC GDI Turbo |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Annual Component Volume: |

450,000 |

|

|

|

|

|

Shipping Method: |

FOB Ship Point |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Component Description: |

Manifold - Exhaust, Dual Wall |

|

|

|

Part Number: |

1201-N0101-01 |

|

|

|

|

|

|

|

|

|

Weekly Component Volume: |

9,574 |

|

|

|

|

|

Packaging Specification: |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Component Quote Level: |

|

|

|

|

|

|

|

|

|

Estimated Product Life: |

10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Costs Broken Out Into Categories with Quantity per Assembly Taken into Account |

|

MANUFACTURING ASSUMPTIONS |

|

|

|

|

GENERAL COMPONENT INFORMATION |

GENERAL MANUFACTURING INFORMATION |

MANUFACTURING RATES |

MANUFACTURING COSTS |

MARK-UP COSTS |

TOTAL COSTS |

|

TOOLING & INVESTMENT |

|

Manufacturing Cost |

Mark-up Cost |

|

Process Information |

|

Projected Operating Pattern |

|

Minimum Calculated Cycles Time |

|

Project Process Requirement |

|

|

|

| Item |

Reference # |

Part Description |

Part Number |

QTY Per Assembly |

Primary Process Description |

OEM/Supplier Classification |

Material

Specification |

Labor

Classification |

Burden

Classification |

Kolwich:

Default calculated in Manufacturing Assumption Section

Finished Pieces Per Hour |

Kolwich: Default Calculated in Manufacturing Assumption Section

Number of Operators |

Number of Lines |

Parallel Processing Multiplier |

Kolwich:

Default calculated in Manufacturing Assumption Section

Material Usage "lbs" |

Material Cost $/lb

(DB) |

Labor Rate

$/Hour

(DB) |

Burden Rate

$/Hour

(DB) |

Applied Burden Rate $/Hour |

Material Cost |

Labor/ Part |

Burden/ Part |

Total 1 =

Material + Labor + Burden |

End Item Scrap Rate

(DB) |

SG&A Rate

(DB) |

Profit Rate

(DB) |

ED&T/ R&D Rate

(DB) |

Total Mark-up Rate |

Total Mark-up Cost |

Total 2 =

Total 1 + Total Mark-up |

Total 3 =

Total 2 * Qty per Ass'y |

|

Tooling Assumptions "x1000 " |

Investment Assumptions "x1000 " |

|

Material |

Labor |

Burden |

Total Mfg'ing Cost (Component/ Assembly) |

End Item Scrap |

SG&A |

Profit |

ED&T-R&D |

Total Markup Cost (Component/ Assembly) |

|

Process & Equipment Assumptions |

Tooling/Fixturing and Gauge Assumptions |

|

Days/Week |

Shifts./ Day |

Hrs./ Shift |

Hrs./ Wk |

Wks./ Yr. |

Hrs./ Yr. |

|

Kolwich:

Based On Weekly CPV

Pcs../ Hr. (100% Eff..) |

Cycle Time/Operation "Sec." |

Efficiency % |

Pcs../ Hr.

@ Stated Efficiency |

Cycle Time/Operation @ Stated Efficiency "Sec." |

|

Kolwich:

Munro Process Time is based on sequential serial processing with single operator.

Lean Design Calculation for Complete Process Time "Sec." |

Parallel Operations/Machine or Stations/Line |

Piece/Cycle/Machine |

Tack Time/Machine/Cycle "Seconds" |

Multiplier, If Required for Parallel Processing (1=Nothing) |

Number of Equivalent Machines Required |

Resulting Pieces/Hour |

Resulting Cycle Time/ Part

"Sec. |

Total Number of Direct Operators |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| A |

Tier 1 Supplier or OEM Processing & Assembly (Full Cost mapping) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 |

1A |

Manifold - Exhaust, Dual Wall (Mini) |

1201-N0101-01-02 |

1 |

Cast |

T1 Assembly, Mark-up Applied @ Bottom. |

NiResist Iron, D5S, Cast |

Mold/Cast/Sinter Operator |

Sand Cast, HMC |

141 |

6 |

1.5 |

2 |

7.760 |

$3.50 |

$43.52 |

$150.07 |

$450.21 |

$27.16 |

$1.85 |

$3.19 |

$32.20 |

10.00% |

0.00% |

0.00% |

0.00% |

10.00% |

$3.22 |

$35.42 |

$35.42 |

|

|

|

|

$27.16 |

$1.85 |

$3.19 |

$32.20 |

$3.22 |

$0.00 |

$0.00 |

$0.00 |

$3.22 |

|

Low Pressure, Semi-Permanent Casting, S#1 Mold & Material Prep, S#2 Core Making, S#3 Pour S#4-6 Cooling Stations, S#7 Remove Parts, S#8 Riser Removal and Deburring, S#9 Shaking, S#10 Washing and S#11 pack as WIP. Max Station time 30 seconds, 7 molds, 2 cavities per. |

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

96 |

37.60 |

85% |

113 |

31.96 |

|

76.5 |

11 |

2 |

76.5 |

2.0 |

1.5 |

141 |

25.50 |

6.00 |

|

|

|

| 2 |

1B |

Manifold - Exhaust, Dual Wall (Mini) |

1201-N0101-01-01 |

1 |

Heat Treat, Pre Machine |

T1 Assembly, Mark-up Applied @ Bottom. |

Not Applicable |

Heat Treat Operator |

Heat Treat, MLS, MHC |

129 |

1 |

3 |

1 |

0.000 |

$0.00 |

$46.52 |

$250.00 |

$750.00 |

$0.00 |

$0.36 |

$5.83 |

$6.20 |

0.00% |

0.00% |

0.00% |

0.00% |

0.00% |

$0.00 |

$6.20 |

$6.20 |

|

|

|

|

$0.00 |

$0.36 |

$5.83 |

$6.20 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

Pre Machining:Heat Treat 2 Hours @ 1600F, 1000F for 1 Hour and Slow Cool to room Temp

(4 Hours) |

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

96 |

37.60 |

85% |

113 |

31.96 |

|

- |

1 |

300 |

25,200 |

1.0 |

3.0 |

129 |

28.00 |

1.00 |

|

|

|

| 3 |

1C |

Manifold - Exhaust, Dual Wall (Mini) |

1201-N0101-01 |

1 |

Machining |

T1 Assembly, Mark-up Applied @ Bottom. |

Not Applicable |

Mold/Cast/Sinter Operator |

CNC Machining, MHC |

120 |

3 |

3 |

1.5 |

0.000 |

$0.00 |

$43.52 |

$45.00 |

$202.50 |

$0.00 |

$1.09 |

$1.69 |

$2.78 |

0.00% |

0.00% |

0.00% |

0.00% |

0.00% |

$0.00 |

$2.78 |

$2.78 |

|

|

|

|

$0.00 |

$1.09 |

$1.69 |

$2.78 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

Single Spindle, 4 Axis CNC Machines, inline washer with convertible nests, and air test with convertible fixturing. |

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

96 |

37.60 |

85% |

113 |

31.96 |

|

90 |

1 |

1 |

90.0 |

1.5 |

3.0 |

120 |

30.00 |

3.00 |

|

|

|

| 4 |

2A |

Manifold - Exhaust, (Chrysler) |

1201-B0101-01-02 |

1 |

Cast |

T1 Assembly, Mark-up Applied @ Bottom. |

Nodular Iron, Cast |

Mold/Cast/Sinter Operator |

Sand Cast, HMC |

-145 |

6 |

1.5 |

1 |

-12.920 |

$0.35 |

$43.52 |

$150.07 |

$225.11 |

-$4.52 |

-$1.81 |

-$1.56 |

-$7.89 |

5.00% |

0.00% |

0.00% |

0.00% |

5.00% |

-$0.39 |

-$8.28 |

-$8.28 |

|

|

|

|

-$4.52 |

-$1.81 |

-$1.56 |

-$7.89 |

-$0.39 |

$0.00 |

$0.00 |

$0.00 |

-$0.39 |

|

Low Pressure, Semi-Permanent Casting, S#1 Mold & Material Prep, S#2 Core Making, S#3 Pour S#4-6 Cooling Stations, S#7 Remove Parts, S#8 Riser Removal and Deburring, S#9 Shaking, S#10 Washing and S#11 pack as WIP. Max Station time 30 seconds, 7 molds, 2 cavities per. |

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

96 |

37.60 |

85% |

113 |

31.96 |

|

74.7 |

1 |

(2) |

74.7 |

1.0 |

1.5 |

-145 |

-24.90 |

6.00 |

|

|

|

| 5 |

2B |

Manifold - Exhaust, Dual Wall (Chrysler) |

1201-B0101-01-01 |

1 |

Heat Treat, Pre Machine |

T1 Assembly, Mark-up Applied @ Bottom. |

Not Applicable |

Heat Treat Operator |

Heat Treat, MLS, MHC |

-125 |

1 |

2.5 |

1 |

0.000 |

$0.00 |

$46.52 |

$250.00 |

$625.00 |

$0.00 |

-$0.37 |

-$5.00 |

-$5.37 |

0.00% |

0.00% |

0.00% |

0.00% |

0.00% |

$0.00 |

-$5.37 |

-$5.37 |

|

|

|

|

$0.00 |

-$0.37 |

-$5.00 |

-$5.37 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

Pre Machining:Heat Treat 2 Hours @ 1600F, 1000F for 1 Hour and Slow Cool to room Temp

(4 Hours |

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

96 |

37.60 |

85% |

113 |

31.96 |

|

- |

1 |

(100) |

7,200 |

1.0 |

2.5 |

-125 |

-28.80 |

1.00 |

|

|

|

| 6 |

2C |

Manifold - Exhaust, Dual Wall (Chrysler) |

1201-B0101-01 |

1 |

Machining |

T1 Assembly, Mark-up Applied @ Bottom. |

Not Applicable |

Mold/Cast/Sinter Operator |

CNC Machining, MHC |

-120 |

3 |

3 |

1 |

0.000 |

$0.00 |

$43.52 |

$45.00 |

$135.00 |

$0.00 |

-$1.09 |

-$1.13 |

-$2.21 |

0.00% |

0.00% |

0.00% |

0.00% |

0.00% |

$0.00 |

-$2.21 |

-$2.21 |

|

|

|

|

$0.00 |

-$1.09 |

-$1.13 |

-$2.21 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

Single Spindle, 4 Axis CNC Machines, inline washer with convertible nests, and air test with convertible fixturing. |

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

96 |

37.60 |

85% |

113 |

31.96 |

|

90 |

1 |

(1) |

90.0 |

1.0 |

3.0 |

-120 |

-30.00 |

3.00 |

|

|

|

| 6 |

|

|

0 |

|

|

|

|

|

#DIV/0! |

0 |

1 |

1 |

0.000 |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

$0.00 |

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

0 |

#DIV/0! |

85% |

0 |

#DIV/0! |

|

- |

- |

- |

- |

1.0 |

1.0 |

#DIV/0! |

#DIV/0! |

- |

|

|

|

| 7 |

|

0 |

|

|

|

|

|

#DIV/0! |

0 |

1 |

1 |

0.000 |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

$0.00 |

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

0 |

#DIV/0! |

85% |

0 |

#DIV/0! |

|

- |

- |

- |

- |

1.0 |

1.0 |

#DIV/0! |

#DIV/0! |

- |

|

|

|

| 8 |

|

0 |

|

|

|

|

|

#DIV/0! |

0 |

1 |

1 |

0.000 |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

$0.00 |

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

0 |

#DIV/0! |

85% |

0 |

#DIV/0! |

|

- |

- |

- |

- |

1.0 |

1.0 |

#DIV/0! |

#DIV/0! |

- |

|

|

|

| 9 |

|

0 |

|

|

|

|

|

#DIV/0! |

0 |

1 |

1 |

0.000 |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

$0.00 |

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

0 |

#DIV/0! |

85% |

0 |

#DIV/0! |

|

- |

- |

- |

- |

1.0 |

1.0 |

#DIV/0! |

#DIV/0! |

- |

|

|

|

| 10 |

|

0 |

|

|

|

|

|

#DIV/0! |

0 |

1 |

1 |

0.000 |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

$0.00 |

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

0 |

#DIV/0! |

85% |

0 |

#DIV/0! |

|

- |

- |

- |

- |

1.0 |

1.0 |

#DIV/0! |

#DIV/0! |

- |

|

|

|

| 11 |

|

0 |

|

|

|

|

|

#DIV/0! |

0 |

1 |

1 |

0.000 |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

$0.00 |

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

0 |

#DIV/0! |

85% |

0 |

#DIV/0! |

|

- |

- |

- |

- |

1.0 |

1.0 |

#DIV/0! |

#DIV/0! |

- |

|

|

|

| 12 |

|

0 |

|

|

|

|

|

#DIV/0! |

0 |

1 |

1 |

0.000 |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

$0.00 |

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

0 |

#DIV/0! |

85% |

0 |

#DIV/0! |

|

- |

- |

- |

- |

1.0 |

1.0 |

#DIV/0! |

#DIV/0! |

- |

|

|

|

| 13 |

|

0 |

|

|

|

|

|

#DIV/0! |

0 |

1 |

1 |

0.000 |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

$0.00 |

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

0 |

#DIV/0! |

85% |

0 |

#DIV/0! |

|

- |

- |

- |

- |

1.0 |

1.0 |

#DIV/0! |

#DIV/0! |

- |

|

|

|

| 14 |

|

0 |

|

|

|

|

|

#DIV/0! |

0 |

1 |

1 |

0.000 |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

$0.00 |

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

0 |

#DIV/0! |

85% |

0 |

#DIV/0! |

|

- |

- |

- |

- |

1.0 |

1.0 |

#DIV/0! |

#DIV/0! |

- |

|

|

|

| 15 |

|

|

|

0 |

|

|

|

|

|

#DIV/0! |

0 |

1 |

1 |

0.000 |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

$0.00 |

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

0 |

#DIV/0! |

85% |

0 |

#DIV/0! |

|

- |

- |

- |

- |

1.0 |

1.0 |

#DIV/0! |

#DIV/0! |

- |

|

|

|

| 16 |

|

|

|

0 |

|

|

|

|

|

#DIV/0! |

0 |

1 |

1 |

0.000 |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

#N/A |

$0.00 |

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

5 |

2 |

10 |

100 |

47 |

4700 |

|

0 |

#DIV/0! |

85% |

0 |

#DIV/0! |

|

- |

- |

- |

- |

1.0 |

1.0 |

#DIV/0! |

#DIV/0! |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| D |

Purchase Part - Commodity ( Value taken from Purchase Part Database) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Supplier Account Cost |

Purchase Price/ Unit |

Purchase Price Net, PIA |

Purchase Price Net, End Item |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 3 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 4 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 5 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 6 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 7 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 8 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 9 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 10 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 11 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 12 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 13 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 14 |

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.00 |

$0.00 |

$0.00 |

$0.00 |

|

|

|

|

$0.00 |

|

|

$0.00 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Material |

Labor |

Burden |

TMC |

Scrape |

SG&A |

Profit |

ED&T |

Mark-up Total |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$22.64 |

$0.03 |

$3.03 |

$25.70 |

$2.83 |

$0.00 |

$0.00 |

$0.00 |

$2.83 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Material |

Labor |

Burden |

TMC |

Scrap |

SG&A |

Profit |

ED&T |

Total Mark-up |

|

|

$28.52 |

|

|

|

|

|

|

|

|

|

|

|

|

$28.52 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T1 or OEM Total Manufacturing Cost: |

$22.64 |

$0.03 |

$3.03 |

$25.70 |

$2.83 |

$0.00 |

$0.00 |

$0.00 |

$2.83 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T1 or OEM Mark-Up Rates: |

----- |

----- |

----- |

----- |

0.50% |

6.50% |

6.00% |

2.50% |

15.50% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

(SAC) &T1 or OEM Mark-Up Values: |

0.00 |

----- |

----- |

----- |

$0.14 |

$1.85 |

$1.71 |

$0.71 |

$4.42 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Base Cost Impact to Vehicle: |

$22.64 |

$0.03 |

$3.03 |

$25.70 |

$2.97 |

$1.85 |

$1.71 |

$0.71 |

$7.25 |

|

$32.95 |

|

$0 |

$0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Packaging Cost: |

-$0.12 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Net Cost Impact to Vehicle: |

$32.82 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cost per Piece |

|

Total Amount |

Lump Sum Payment (%) |

Total # of Pieces |

Number of Months |

Interest Rate |

|

Cost per Pallet /Rack |

Total Number of Pallets/ Racks Required |

Number of Parts per Pallet/ Rack |

Supplier, Customer and In-transit Inventory Requirements (Weeks) |

Supplier, Customer and In-transit Inventory Requirements (Parts) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

$0.152 |

|

$303,191 |

0.00% |

2,250,000 |

60 |

5.00% |

|

$380 |

798 |

72 |

6 |

57447 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Cost per Piece |

|

Tier Pad Price Per |

Tier Pads Pallet/Rack |

Divider Pads, Price Per |

Divider Pads Pallet/Rack |

Other #1 Packaging Price Per |

Other #1 Pads Pallet/Rack |

Other #2 Packaging Price Per |

Other #2 Pads Pallet/Rack |

Other #3 Packaging, Price Per |

Other #3 Pads Pallet/Rack |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Expendable Packaging in Piece Cost: |

$0.00 |

|

$0.00 |

0 |

$0.00 |

0 |

$0.00 |

0 |

$0.00 |

0 |

$0.00 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Packaging Cost Total: |

$0.152 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|