268x Filetype XLSX File size 0.17 MB Source: knowledgequity.com.au

Sheet 1: TDABC Exercise

| Time-driven activity-based costing | ||||||||||||

| Exercise | ||||||||||||

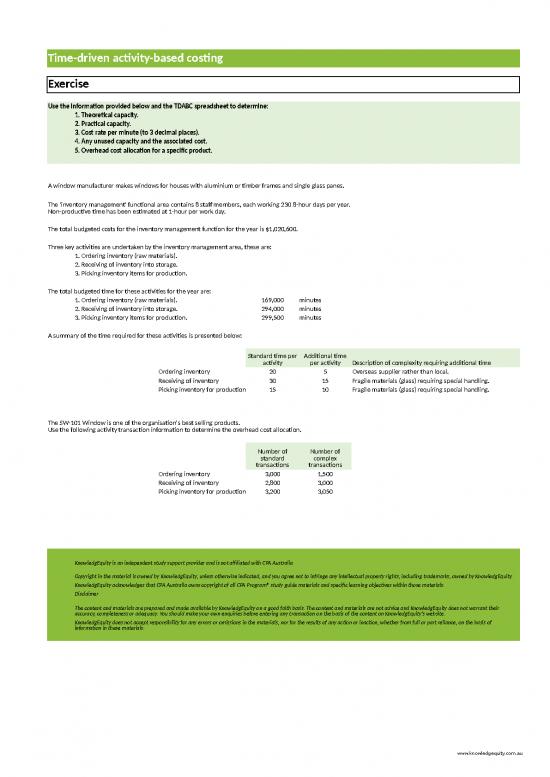

| Use the information provided below and the TDABC spreadsheet to determine: | ||||||||||||

| 1. Theoretical capacity. | ||||||||||||

| 2. Practical capacity. | ||||||||||||

| 3. Cost rate per minute (to 3 decimal places). | ||||||||||||

| 4. Any unused capacity and the associated cost. | ||||||||||||

| 5. Overhead cost allocation for a specific product. | ||||||||||||

| A window manufacturer makes windows for houses with aluminium or timber frames and single glass panes. | ||||||||||||

| The 'inventory management' functional area contains 8 staff members, each working 230 8-hour days per year. Non-productive time has been estimated at 1-hour per work day. |

||||||||||||

| The total budgeted costs for the inventory management function for the year is $1,020,600. | ||||||||||||

| Three key activities are undertaken by the inventory management area, these are: | ||||||||||||

| 1. Ordering inventory (raw materials). | ||||||||||||

| 2. Receiving of inventory into storage. | ||||||||||||

| 3. Picking inventory items for production. | ||||||||||||

| NOTE: You can first attempt the exercise using the blank template that does not contain any formulas to test that you can calculate the items yourself; alternatively you can first use the template with the formulas to help you understand the calculations and then attempt with the blank template. | ||||||||||||

| The total budgeted time for these activities for the year are: | ||||||||||||

| 1. Ordering inventory (raw materials). | 169,000 | minutes | ||||||||||

| 2. Receiving of inventory into storage. | 294,000 | minutes | ||||||||||

| 3. Picking inventory items for production. | 299,500 | minutes | ||||||||||

| A summary of the time required for these activities is presented below: | Go to TDABC spreadsheet with no formulas | |||||||||||

| Standard time per activity | Additional time per activity | Description of complexity requiring additional time | ||||||||||

| Ordering inventory | 20 | 5 | Overseas supplier rather than local. | Go to TDABC spreadsheet with formulas | ||||||||

| Receiving of inventory | 30 | 15 | Fragile materials (glass) requiring special handling. | |||||||||

| Picking inventory for production | 15 | 10 | Fragile materials (glass) requiring special handling. | |||||||||

| The SW-101 Window is one of the organisation's best selling products. Use the following activity transaction information to determine the overhead cost allocation. |

||||||||||||

| Number of standard transactions | Number of complex transactions | |||||||||||

| Ordering inventory | 3,000 | 1,500 | ||||||||||

| Receiving of inventory | 2,800 | 3,000 | ||||||||||

| Picking inventory for production | 3,200 | 3,050 | ||||||||||

| KnowledgEquity is an independent study support provider and is not affiliated with CPA Australia | ||||||||||||

| Copyright in the material is owned by KnowledgEquity, unless otherwise indicated, and you agree not to infringe any intellectual property rights, including trademarks, owned by KnowledgEquity. | ||||||||||||

| KnowledgEquity acknowledges that CPA Australia owns copyright of all CPA Program® study guide materials and specific learning objectives within those materials. | ||||||||||||

| Disclaimer | ||||||||||||

| The content and materials are prepared and made available by KnowledgEquity on a good faith basis. The content and materials are not advice and KnowledgEquity does not warrant their accuracy, completeness or adequacy. You should make your own enquiries before entering any transaction on the basis of the content on KnowledgEquity’s website. | ||||||||||||

| KnowledgEquity does not accept responsibility for any errors or omissions in the materials, nor for the results of any action or inaction, whether from full or part reliance, on the basis of information in these materials. | ||||||||||||

| Using TDABC to allocate indirect costs | Legend: | ||||||||||||||||||||

| input | unprotected bordered cells with blue font and yellow background are input cells | ||||||||||||||||||||

| Theoretical capacity (total time available) in minutes: | |||||||||||||||||||||

| Number of personnel | Work day in hours | Number of minutes in work day |

Number of work days in the period |

Theoretical capacity in minutes |

|||||||||||||||||

| Practical capacity | |||||||||||||||||||||

| Non-productive work time calculator: | |||||||||||||||||||||

| Theoretical capacity in minutes: | Hours per day | Minutes per day | Days per period | Number of personnel | |||||||||||||||||

| Total | |||||||||||||||||||||

| Less: | Time spent by personnel in non-productive work (e.g. training) | - | |||||||||||||||||||

| Equals: | Practical capacity in minutes | ||||||||||||||||||||

| TDABC cost rate per minute | |||||||||||||||||||||

| Total costs to be allocated | |||||||||||||||||||||

| Practical capacity | - | ||||||||||||||||||||

| TDABC cost rate per minute (rounded to three decimal places) | |||||||||||||||||||||

| Budgeted costs and unused capacity | |||||||||||||||||||||

| Activity | Budgeted time (minutes) | Cost rate per minute |

Budgeted costs |

||||||||||||||||||

| (1) Total time and cost | |||||||||||||||||||||

| (2) Total practical capacity and costs | |||||||||||||||||||||

| Unused capacity (2) - (1) | |||||||||||||||||||||

| Budgeted time for standard and complex activity performance | |||||||||||||||||||||

| Product: | |||||||||||||||||||||

| Standard activity performance | Complex activity performance | ||||||||||||||||||||

| Activity | Unit time |

Transact -ions |

Standard time | Additional unit time | Transact -ions |

Additional time | Total time |

||||||||||||||

| Budgeted time | Standard time | Additional time | |||||||||||||||||||

| Budgeted costs allocated to | |||||||||||||||||||||

| Activity | Budgeted activity time (mins) |

Cost rate per minute |

Costs allocated |

||||||||||||||||||

| Total times | |||||||||||||||||||||

no reviews yet

Please Login to review.