|

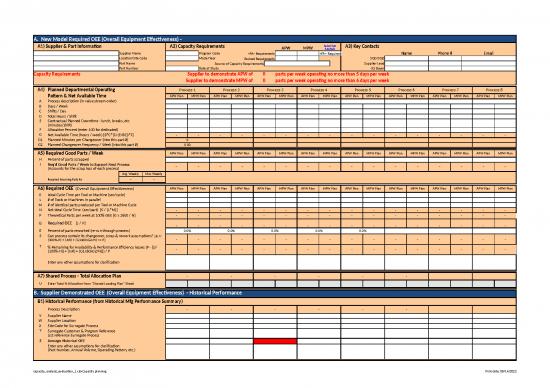

A. New Model Required OEE (Overall Equipment Effectiveness) - |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

1 |

|

|

|

|

1 |

0 |

0 |

1 |

|

A1) Supplier & Part Information |

|

|

|

|

A2) Capacity Requirements |

|

|

|

|

|

|

|

|

|

Average Production Weekly (APW) is the average weekly quantity of parts specified by KS to the supplier.

The APW is the quantity of parts the supplier needs to be capable of producing to meet the planned long-term "Average" requirement of the supplier's KS customer plants.

Note: Plant weekly requirements vary

APW |

Maximum Production Weekly (MPW) is the maximum weekly quantity of parts specified by KS to the supplier.

The MPW is the quantity of parts the supplier needs to be capable of producing to meet the planned short-term (up to 90 days) "Peak" requirement of the supplier's KS customer plants.

MPW |

Select for Analysis |

A3) Key Contacts |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Long-Lead Tool Order |

<PA> Requirements |

|

|

|

|

|

|

|

|

|

|

|

|

|

Supplier Name |

|

Program Code |

<PA> Requirements |

|

|

<PA> Requirements |

|

|

|

|

Name |

Phone # |

Email |

|

|

WebQuote |

Revised Requirements |

|

|

|

|

|

|

|

|

|

|

|

|

|

Location/Site Code |

|

Model Year |

Revised Requirements |

|

|

|

|

|

|

SQD/SQD |

|

|

|

|

|

SOBA (Supplier On Board Agreement) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Part Name |

|

Source of Capacity Requirements |

|

|

|

|

|

Supplier Lead |

|

|

|

|

|

CPA (Commercial and Program Agreement) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Part Number |

|

Enter date in "dd-mmm-yyyy" format, e.g. 28-Jun-2014

"Date of Study" is the date this CAR form was completed.

Date of Study |

|

|

|

|

|

KS Buyer |

|

|

|

|

|

Capacity Study |

|

|

|

|

|

|

|

|

|

|

|

|

|

Capacity Requirements |

|

|

|

Supplier to demonstrate APW of |

0 |

parts per week operating no more than 5 days per week |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Other (specify in Notes at bottom left) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Supplier to demonstrate MPW of |

0 |

parts per week operating no more than 6 days per week |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A4) |

Planned Departmental Operating |

|

|

|

Process 1 |

Process 2 |

Process 3 |

Process 4 |

Process 5 |

Process 6 |

Process 7 |

Process 8 |

|

|

|

|

|

Pattern & Net Available Time |

|

|

|

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

|

|

|

|

A |

Process description (in value stream order) |

|

|

|

|

|

|

|

|

|

|

|

|

|

B |

Days / Week |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C |

Shifts / Day |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

D |

Total Hours / Shift |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

E |

Contractual Planned Downtime - lunch, breaks, etc.

(minutes/shift) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

F |

Where there are 2 or more parts made in the same manufacturing process, an allocation of less than 100% per part is required in this row (F).

For shared processes, Allocation % includes changeover time into this part number

Where allocation is less than 100% (2 or more parts per process), a Shared Loading Plan must be completed.

Allocation Percent (enter 100 for dedicated) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G |

Net Available Time (hours / week) [B*C*(D-(E/60))*F] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G1 |

Planned Minutes per Changeover (into this part #) |

Per tool or machine

0 |

Per tool or machine

|

Per tool or machine

|

Per tool or machine

|

Per tool or machine

|

Per tool or machine

|

Per tool or machine

|

Per tool or machine

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

G2 |

Planned Changeover Frequency / Week (into this part #) |

Per tool or machine

0.00 |

Per tool or machine

|

Per tool or machine

|

Per tool or machine

|

Per tool or machine

|

Per tool or machine

|

Per tool or machine

|

Per tool or machine

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A5) Required Good Parts / Week |

|

|

|

|

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

H |

Percent of parts scrapped |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J |

Req'd Good Parts / Week to Support Next Process

(Accounts for the scrap loss of each process) |

Material or components required for Process 2 equals Process 2 Required Good Parts per Week divided by (100% minus Process 2 scrap rate)

- |

Material or components required for Process 2 equals Process 2 Required Good Parts per Week divided by (100% minus Process 2 scrap rate)

- |

Material or components required for Process 3 equals Process 3 Required Good Parts per Week divided by (100% minus Process 3 scrap rate)

- |

Material or components required for Process 3 equals Process 3 Required Good Parts per Week divided by (100% minus Process 3 scrap rate)

- |

Material or components required for Process 4 equals Process 4 Required Good Parts per Week divided by (100% minus Process 4 scrap rate)

- |

Material or components required for Process 4 equals Process 4 Required Good Parts per Week divided by (100% minus Process 4 scrap rate)

- |

Material or components required for Process 5 equals Process 5 Required Good Parts per Week divided by (100% minus Process 5 scrap rate)

- |

Material or components required for Process 5 equals Process 5 Required Good Parts per Week divided by (100% minus Process 5 scrap rate)

- |

Material or components required for Process 6 equals Process 6 Required Good Parts per Week divided by (100% minus Process 6 scrap rate)

- |

Material or components required for Process 6 equals Process 6 Required Good Parts per Week divided by (100% minus Process 6 scrap rate)

- |

Material or components required for Process 7 equals Process 7 Required Good Parts per Week divided by (100% minus Process 7 scrap rate)

- |

Material or components required for Process 7 equals Process 7 Required Good Parts per Week divided by (100% minus Process 7 scrap rate)

- |

Material or components required for Process 8 equals Process 8 Required Good Parts per Week divided by (100% minus Process 8 scrap rate)

- |

Material or components required for Process 8 equals Process 8 Required Good Parts per Week divided by (100% minus Process 8 scrap rate)

- |

Material or components required for Process 8 equals Process 8 Required Good Parts per Week divided by (100% minus Process 8 scrap rate)

- |

Material or components required for Process 8 equals Process 8 Required Good Parts per Week divided by (100% minus Process 8 scrap rate)

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Avg. Weekly |

Max Weekly |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Required Incoming Parts for |

|

Material or components required for Process 1 equals Process 1 Required Good Parts per Week divided by (100% minus Process 1 scrap rate)

- |

Material or components required for Process 1 equals Process 1 Required Good Parts per Week divided by (100% minus Process 1 scrap rate)

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A6) Required OEE (Overall Equipment Effectiveness) |

|

|

|

|

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

APW Plan |

MPW Plan |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

K |

For processes with multiple operations, use constraint.

Ideal Cycle Time per Tool or Machine (sec/cycle) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

L |

# of Tools or Machines in parallel |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

M |

# of identical parts produced per Tool or Machine Cycle |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

N |

Net Ideal Cycle Time (sec/part) [K / (L*M)] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

P |

Assumes no unplanned breakdowns, no changeovers, and maintenance is done outside of planned production time.

Theoretical Parts per week at 100% OEE [G x 3600 / N] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Q |

Required OEE [J / P] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

R |

Percent of parts reworked (re-run through process) |

0.0% |

0.0% |

0.0% |

0.0% |

0.0% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

S |

Can process contain its changeover, scrap & rework assumptions? [Is J/(100%-H) + (JxR) + (G1x60xG2/N) <= P] |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

If NO,

Req'd Good Parts + Scrap + Rework + Parts lost to Changeover > Max Possible Parts

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

T |

% Remaining for Availability & Performance Efficiency losses {P - [(J/(100%-H)) + (JxR) + (G1x60xG2/N)]} / P |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter any other assumptions for clarification |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

A7) Shared Process - Total Allocation Plan |

|

|

|

|

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

U |

Where allocation is less than 100%, a Shared Loading Plan must be completed.

Enter Total % Allocation from "Shared Loading Plan" Sheet |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B. Supplier Demonstrated OEE (Overall Equipment Effectiveness) - Historical Performance |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

B1) Historical Performance (from Historical Mfg Performance Summary) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Process Description |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

V |

Supplier Name |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

W |

Supplier Location |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

X |

Site Code for Surrogate Process |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Y |

Surrogate Customer & Program Reference

List reference Surrogate Process |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Z |

Average Historical OEE |

For shared process OEE calculation, Net Available Time must include changeovers

|

For shared process OEE calculation, Net Available Time must include changeovers

|

For shared process OEE calculation, Net Available Time must include changeovers

|

For shared process OEE calculation, Net Available Time must include changeovers

|

For shared process OEE calculation, Net Available Time must include changeovers

|

For shared process OEE calculation, Net Available Time must include changeovers

|

For shared process OEE calculation, Net Available Time must include changeovers

|

For shared process OEE calculation, Net Available Time must include changeovers

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Enter any other assumptions for clarification

(Part Number, Annual Volume, Operating Pattern, etc.) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Used to independently evaluate the specific process' potential for producing good parts. This part estimate does not take into account a blocked condition from a downstream process nor a starved condition from an upstream process. This part estimate assumes an unlimited supply of parts entering the process and is simply based on the specific process' Demonstrated OEE. This value does not represent the Overall Process Predicted Good Parts / Week. For that value, refer to the summary section at the bottom of this tab.

B2) Process Specific Weekly Part Estimate [P * Z] |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

C. Gap Analysis - Required OEE vs. Demonstrated OEE; Predicted Good Parts / Week |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Process Description |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

APW Result |

MPW Result |

APW Result |

MPW Result |

APW Result |

MPW Result |

APW Result |

MPW Result |

APW Result |

MPW Result |

APW Result |

MPW Result |

APW Result |

MPW Result |

APW Result |

MPW Result |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Demonstrated OEE > Required OEE? (Is Z > Q?) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Predicted Good Parts per wk |

Average |

Maximum |

|

|

|

|

|

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

Required Capacity

(APW/MPW) |

0 |

0 |

|

|

|

Historical Demonstrated OEE |

0.0% |

0.0% |

0.0% |

0.0% |

0.0% |

0.0% |

0.0% |

0.0% |

0.0% |

|

|

|

These Predicted Good Part / Week APW and MPW values are recorded as PPC (Purchased Part Capacity) in the Ford capacity systems GCP (Vehicle) and MCPV (Powertrain).

If any OEE > 100% in this report, the analysis must be corrected prior to entering the PPC values into the Ford system. Contact your STA engineer for assistance.

Note: Estimated to be the lowest value in row B5 reduced by planned scrap losses (row H) of successive operations.

Note 2: The APPC/MPPC values are calculated using the planned scrap rate, not the demonstrated scrap rate; and if the actual scrap / rework rates are higher than the planned rates there is further risk to the capacity.

Planned Capacity |

0 |

0 |

|

|

|

Req'd OEE at APW |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

|

|

|

|

Req'd OEE at MPW |

- |

- |

- |

- |

- |

- |

- |

- |

|

|

|

|

NOTES |

|

Capacity Study Number: |

|

|

|

|

|

Req'd Demand OEE at APW |

97.8% |

- |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

Req'd Demand OEE at MPW |

111.1% |

- |

- |

- |

- |

- |

- |

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

SUPPLIER OPERATION MANAGEMENT APPROVAL |

|

|

|

|

|

|

|

|

|

|

|

|

SQM Use |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Version 1.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Authorized Representative Name / Title |

|

|

|

|

Email |

|

|

|

|

|

|

|

|

|

Site Engineer |

|

|

|

|

|

|

SQD |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Signature |

|

|

|

Date |

|

|

|

|

Phone Number |

|

|

|

|

|

|

Signature/Date |

|

|

|

|

|

|

Signature/Date |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Yellow |

|

|

|

Yellow |

|

|

|

Yellow |

|

|

|

Yellow |

|

|

|

Yellow |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

J |

K |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

column |

APPC |

column |

MPPC |

|

Row 60 |

Row 60 |

|

Row 60 |

Row 60 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

g |

0 |

i |

0 |

|

- |

- |

|

0 |

0 |

|

103 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

k |

0 |

m |

0 |

|

- |

- |

|

0 |

0 |

|

104 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

o |

0 |

q |

0 |

|

- |

- |

|

0 |

0 |

|

105 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

s |

0 |

u |

0 |

|

- |

- |

|

0 |

0 |

|

106 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

w |

0 |

y |

0 |

|

- |

- |

|

0 |

0 |

|

107 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

aa |

0 |

ac |

0 |

|

- |

- |

|

0 |

0 |

|

108 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ae |

0 |

ag |

0 |

|

- |

- |

|

0 |

0 |

|

109 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

ai |

0 |

ak |

0 |

|

- |

- |

|

0 |

0 |

|

110 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

999999999999 |

|

999999999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9999999 |

|

9999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9999999 |

|

9999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9999999 |

|

9999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9999999 |

|

9999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9999999 |

|

9999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9999999 |

|

9999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9999999 |

|

9999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

9999999 |

|

9999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.0% |

Process 2 |

100.0% |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.0% |

Process 3 |

100.0% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.0% |

Process 4 |

100.0% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.0% |

Process 5 |

100.0% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.0% |

Process 6 |

100.0% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.0% |

Process 7 |

100.0% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

0.0% |

Process 8 |

100.0% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

999999999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

APPC |

999999999999 |

|

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

MPPC |

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

999999999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

999999999999 |

Round APPC |

999999999999 |

999999999999 |

999999999999 |

999999999999 |

999999999999 |

999999999999 |

999999999999 |

999999999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

999999999999 |

Round MPPC |

999999999999 |

999999999999 |

999999999999 |

999999999999 |

999999999999 |

999999999999 |

999999999999 |

999999999999 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|