202x Filetype XLSX File size 0.04 MB Source: www.savethechildren.net

Sheet 1: Request for Proposal

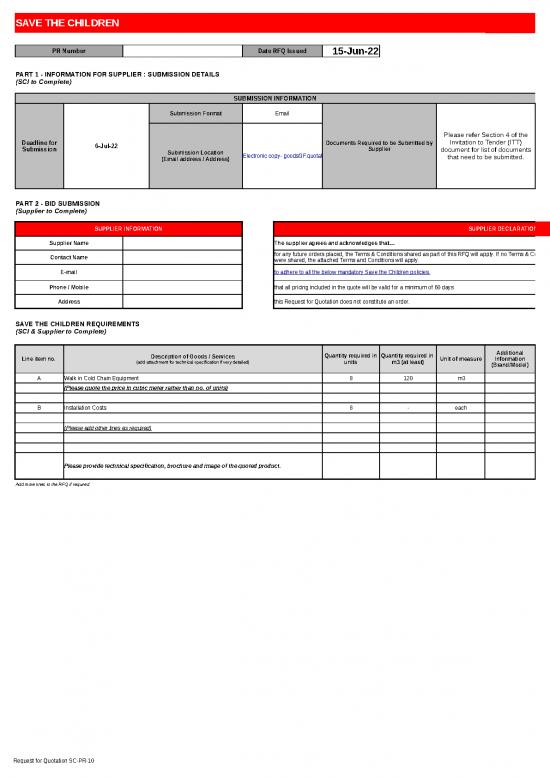

| SAVE THE CHILDREN | REQUEST FOR QUOTATION | |||||||||||||

| Version No. 1.0 / 110621 | ||||||||||||||

| PR Number | Date RFQ Issued | 15-Jun-22 | ||||||||||||

| PART 1 - INFORMATION FOR SUPPLIER : SUBMISSION DETAILS (SCI to Complete) |

||||||||||||||

| SUBMISSION INFORMATION | REQUIREMENTS INFORMATION | |||||||||||||

| Deadline for Submission | 6-Jul-22 | Submission Format | Documents Required to be Submitted by Supplier | Please refer Section 4 of the Invitation to Tender (ITT) document for list of documents that need to be submitted. | Date Goods / Services Required | Oct-22 | ||||||||

| Submission Location (Email address / Address) |

Electronic copy- goodsGF.quotation@savethechildren.org; | Delivery Address for Goods / Services | Delivery and Installation at Sites | |||||||||||

| Requirement Incoterms | ||||||||||||||

| PART 2 - BID SUBMISSION (Supplier to Complete) |

||||||||||||||

| SUPPLIER INFORMATION | SUPPLIER DECLARATIONS | |||||||||||||

| Supplier Name | The supplier agrees and acknowledges that… | Supplier Acceptance | Comments | |||||||||||

| Contact Name | for any future orders placed, the Terms & Conditions shared as part of this RFQ will apply. If no Terms & Conditions were shared, the attached Terms and Conditions will apply. | |||||||||||||

| to adhere to all the below mandatory Save the Children policies. | ||||||||||||||

| Phone / Mobile | that all pricing included in the quote will be valid for a minimum of 60 days | |||||||||||||

| Address | this Request for Quotation does not constitute an order. | |||||||||||||

| SAVE THE CHILDREN REQUIREMENTS (SCI & Supplier to Complete) |

||||||||||||||

| Line item no. | Description of Goods / Services (add attachment for technical specification if very detailed) |

Quantity required in units | Quantity required in m3 (at least) | Unit of measure | Additional Information (Brand/Model) | Currency | Lead Time for Delivery | Unit Price | Total Price | |||||

| A | Walk in Cold Chain Equipment | 8 | 120 | m3 | ||||||||||

| (Please quote the price in cubic meter rather than no. of units) | ||||||||||||||

| B | Installation Costs | 8 | - | each | ||||||||||

| (Please add other lines as required) | ||||||||||||||

| Please provide technical specification, brochure and image of the quoted product. | ||||||||||||||

| Add more lines to the RFQ if required | Subtotal | - | ||||||||||||

| Delivery Charge | ||||||||||||||

| Other charges (if applicable) |

||||||||||||||

| Value added tax (VAT) | ||||||||||||||

| Total | - | |||||||||||||

| Technical Specification Form (TSF) of Walk-in Cooler | |||||

| Manufacturer | |||||

| Brand | |||||

| Type/Model | |||||

| Country of Origin | |||||

| S.No. | Parameters | Specification | Bidder Comments | ||

| Complies Yes/No |

Reference page no in catalogue | Remarks | |||

| 1 | Description of Function | Prefabricated cold room, walk-in type, for storage of vaccines. | |||

| 2 | Operational Requirements | Prefabricated/prefab cold room, walk-in type, supplied with all necessary mechanical and electrical fittings and equipment for quick and easy installation in the field. | |||

| 3 | System Configuration | The system consists of: | |||

| · Cold room, walk-in type | |||||

| · Dual Refrigeration system | |||||

| · DG set | |||||

| · Voltage stabilizer | |||||

| 4 | Technical Specifications | Size of the walk in cooler should be minimum 15 m3 | |||

| The unit is designed to operate from a mains supply of 380-400 volts, 50Hz, 3 Phase | |||||

| The complete unit is also designed for installation in a warehouse in order to meet temperature design standards. | |||||

| Operating temperature of the cold room is +2°C to +8°C which is maintained even in environments where ambient temperature may be as high as +45°C. | |||||

| Prefabricated, modular walk-in cold room, complete with floor, wall, and ceiling panels. | |||||

| Internal temperature +2°C to +8°C, adjustable. | |||||

| Insulation material:- • Chlorofluorocarbon (CFC) free polyurethane, • Foamed-in-place • Insulation thickness minimum120 mm |

|||||

| Internal and external surfaces of hot-dipped galvanized steel sheet, white polyester coating, and floor clad with non-slip material. | |||||

| Door is approximately 700-800 mm wide, 2000 mm high, with door frame heating | |||||

| Rooms are equipped with shelving system | |||||

| There should be provision to continuously monitor the temperature of the storage compartment (data logger) | |||||

| External thermometer with remote sensor on front panel. | |||||

| Room equipped with dual refrigeration system (100% stand by). | |||||

| Automatic defrosting. | |||||

| Plastic strip curtain in doorway. | |||||

| Door equipped with heavy duty hinges and lock with internal safety release. | |||||

| Room equipped with individual alarm systems with sound and light signals. | |||||

| Refrigerant CFC-free or that material that has low or zero GWP | |||||

| Servo Voltage Stabilizer: • KVA rating as suitable • For three phase: Input Voltage 275-440 V 50 Hz; Output: 400 V+/- 1%, 50 Hz. Three phase four wires. • Common Specs: Facilities for manual control of output. Arrangements for direct supply bypassing the stabilizer in case of failures, voltmeter and indicators on front panel, suitable safety and protection devices. Quick start arrangement for bypassing restart delay. |

|||||

| Diesel Generator set: Suitable minimum 15KVA standby generator set, diesel operated, 380-400V AC 50 Hz (3P-N). Three phase depending upon voltage requirement of the cold room. The diesel tank capacity must allow for a minimum of 8 hours continuous running. Generator must have sound proof canopy. Complete installation including earthing and civil works and fitting to be done such that the smoke must be emitted outside the generator. Generator must be complete with AMF (Automatic Mains Failure) panel and battery. |

|||||

| 5 | Accessories, spares and consumables | All standard accessories, consumables and parts required to operate the equipment, including all standard tools and cleaning and lubrication materials, to be included in the offer. Bidders must specify the quantity of every item included in their offer (including items not specified above). | |||

| 6 | Operating Environment | The product offered shall be designed to be stored and to operate normally under Nepal's Power Supply, Climate, Temperature, low and high Humidity conditions. | |||

| Unit power supply: 380-400V/ 50 Hz AC three phase fitted with appropriate plugs and sockets. | |||||

| 7 | Standards and Safety Requirements | Should be WHO PQS certified product or | |||

| Electrical and refrigeration components and the panels must have international approvals like EUL, TUV, CE, NSF,FDA. | |||||

| 8 | User Training | Must provide user training (including how to use and maintain the equipment). | |||

| 9 | Warranty | Comprehensive warranty for 2 years after acceptance. | |||

| 10 | Maintenance Service During Warranty Period | During the warranty period supplier must ensure preventive maintenance and corrective/breakdown maintenance whenever required. | |||

| 11 | Installation and Commissioning | The bidder must arrange for the equipment to be installed and commissioned by certified or qualified personnel; any prerequisites for installation to be communicated to the purchaser in advance, in detail. | |||

| 12 | Documentation | User (Operating) manual in English | |||

| Service (Technical / Maintenance) manual in English | |||||

| List of important spare parts and accessories with their part numbers and costing. | |||||

| Certificate of inspection from an independent laboratory approved/recognized by WHO/UNICEF/or internationally reputed lab. | |||||

| Bidder must completely fill the Technical Specification Form (TSF) | |||||

| Only yes/no/all complies should not be written. | |||||

| Page number in the catalogue of all the required parameters must be clearly mentioned and highlighted. | |||||

| Failure in doing so may lead to rejection of bid from technical committee. | |||||

no reviews yet

Please Login to review.