261x Filetype XLSX File size 0.11 MB Source: www.oregon.gov

Sheet 1: ArchitectConstructCluster

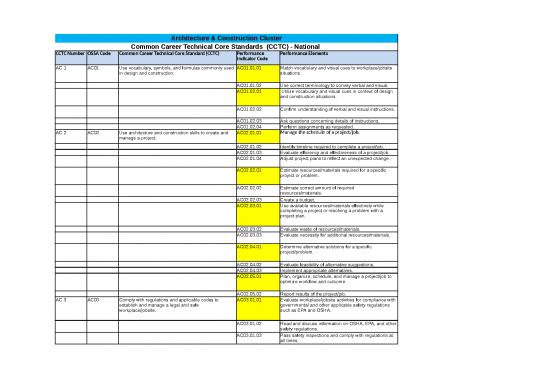

| Architecture & Construction Cluster | ||||

| Common Career Technical Core Standards (CCTC) - National | ||||

| CCTC Number | OSSA Code | Common Career Technical Core Standard (CCTC) | Performance Indicator Code | Performance Elements |

| AC 1 | AC01 | Use vocabulary, symbols, and formulas commonly used in design and construction. | AC01.01.01 | Match vocabulary and visual cues to workplace/jobsite situations. |

| AC01.01.02 | Use correct terminology to convey verbal and visual. | |||

| AC01.02.01 | Utilize vocabulary and visual cues in context of design and construction situations. |

|||

| AC01.02.02 | Confirm understanding of verbal and visual instructions. | |||

| AC01.02.03 | Ask questions concerning details of instructions. | |||

| AC01.02.04 | Perform assignments as requested. | |||

| AC 2 | AC02 | Use architecture and construction skills to create and manage a project. | AC02.01.01 | Manage the schedule of a project/job. |

| AC02.01.02 | Identify timeline required to complete a project/job. | |||

| AC02.01.03 | Evaluate efficiency and effectiveness of a project/job. | |||

| AC02.01.04 | Adjust project plans to reflect an unexpected change. | |||

| AC02.02.01 | Estimate resources/materials required for a specific project or problem. |

|||

| AC02.02.02 | Estimate correct amount of required resources/materials. | |||

| AC02.02.03 | Create a budget. | |||

| AC02.03.01 | Use available resources/materials effectively while completing a project or resolving a problem with a project plan. |

|||

| AC02.03.02 | Evaluate waste of resources/materials. | |||

| AC02.03.03 | Evaluate necessity for additional resources/materials. | |||

| AC02.04.01 | Determine alternative solutions for a specific project/problem. |

|||

| AC02.04.02 | Evaluate feasibility of alternative suggestions. | |||

| AC02.04.03 | Implement appropriate alternatives. | |||

| AC02.05.01 | Plan, organize, schedule, and manage a project/job to optimize workflow and outcome. |

|||

| AC02.05.02 | Report results of the project/job. | |||

| AC 3 | AC03 | Comply with regulations and applicable codes to establish and manage a legal and safe workplace/jobsite. | AC03.01.01 | Evaluate workplace/jobsite activities for compliance with governmental and other applicable safety regulations such as EPA and OSHA. |

| AC03.01.02 | Read and discuss information on OSHA, EPA, and other safety regulations. | |||

| AC03.01.03 | Pass safety inspections and comply with regulations at all times. | |||

| AC03.02.01 | Identify workplace/jobsite environmental hazards of a given situation. |

|||

| AC03.02.02 | Follow safe practices relating to environmental hazards. | |||

| AC03.02.03 | Identify workplace hazards common to design and construction situations. | |||

| AC03.03.01 | Identify governmental regulations and national, state, and/or local building codes that apply to a given workplace/jobsite. |

|||

| AC03.03.02 | Follow governmental regulations and building codes. | |||

| AC03.03.03 | Follow industry regulations and building codes. | |||

| AC03.03.04 | Follow jurisdictional regulations and building codes. | |||

| AC03.03.05 | Use information given in regulations and codes correctly. | |||

| AC03.03.06 | Pass job inspections and comply with regulations at all times. | |||

| AC03.03.07 | Pass required substance abuse screening. | |||

| AC03.04.01 | Use MSDS (Material Safety Data Sheets) information for the management, use, and disposal of materials. |

|||

| AC03.04.02 | Obtain, understand, and follow MSDS (Material Safety Data Sheets) information. | |||

| AC03.04.03 | Use materials safely. | |||

| AC 4 | AC04 | Understand the nature and scope of the Architecture &Construction Career ClusterTM and the role architecture and construction play in society and the economy. | AC04.01.01 | Describe how relationships between trades/professions can facilitate smooth workflow and outcome to meet project goals. |

| AC04.01.02 | Coordinate work between trades. | |||

| AC04.02.01 | Explain how the hierarchy of roles on a jobsite facilitates smooth workflow and outcome to meet project goals. |

|||

| AC04.02.02 | Incorporate job functions in the reporting chain of supervision. | |||

| AC04.02.03 | Evaluate the safety issues and responsibilities managed by each level of supervision. | |||

| AC 5 | AC05 | Understand the roles and responsibilities among trades and professions, including labor/management relationships. | AC05.01.01 | Analyze a proposed contract in terms of the company's position and union's position in labor contract negotiations. |

| AC05.01.02 | Document how quality improves profitability. | |||

| AC05.01.03 | Report on issues that affect quality. | |||

| AC05.02.01 | Assess a situation for compliance with terms of a contract. |

|||

| AC05.03.01 | Discuss the role and responsibilities among the trades/professions in the work environment. |

|||

| AC 6 | AC06 | Read, interpret, and use technical drawings, documents, and specifications to plan a project. | AC06.01.01 | Interpret drawings used in project planning. |

| AC06.01.02 | Recognize elements and symbols of blueprints and drawings. | |||

| AC06.02.01 | Recognize how specifications and standards are arranged for proper access. |

|||

| AC06.02.02 | Use specifications and standards. | |||

| AC06.02.03 | Apply specifications and standards appropriately. | |||

| AC06.03.01 | Use architect's plan, manufacturer's illustrations and other materials to communicate specific data and visualize proposed work. |

|||

| AC06.03.02 | Sketch/draw/illustrate concepts and ideas. | |||

| AC06.03.03 | Draw or sketch plan/layout to be completed. | |||

| AC06.03.04 | Use proper measurements to determine layout. | |||

| AC06.04.01 | Describe the written standards and specifications that apply. |

|||

| AC06.04.02 | Interpret and explain standards and specifications. | |||

| AC 7 | AC07 | Evaluate a wide range of career pathway opportunities for success in architecture and construction careers. | AC07.01.01 | Research and match career opportunities based upon their fit with personal career goals. |

| AC07.01.02 | Locate and interpret career information for at least one career pathway within the cluster. | |||

| AC07.01.03 | Identify job requirements for the career cluster/pathway. | |||

| AC07.01.04 | Identify educational and credentialing requirements for careers within the cluster. | |||

| AC07.02.01 | Match personal interests and aptitudes to careers when researching opportunities within the pathways. |

|||

| AC07.02.02 | Identify personal interests and aptitudes. | |||

| AC07.02.03 | Identify job requirements and characteristics for selected careers. | |||

| AC07.02.04 | Compare personal interests and aptitudes with job requirements and characteristics of the career selected. | |||

| AC07.02.05 | Modify career goals based on results of personal interests and aptitudes with career requirements and characteristics. | |||

| AC07.03.01 | Develop a career plan for advancement in architecture and construction careers. |

|||

| Architecture & Construction Cluster-- Carpentry Focus Area | ||||

| Oregon Skill Sets | ||||

| CCTC Number | OSSA Code | Common Career Technical Core Standard (CCTC) | Performance Indicator Code | Performance Elements |

| ACCR01 | Identify building materials, fasteners, adhesives, and their uses. | ACCR01.01.01 | Identify various types of building materials and their uses. | |

| ACCR01.01.02 | State the uses of various types of hardwoods and softwoods. | |||

| ACCR01.01.03 | Identify the different grades and markings of wood building materials. | |||

| ACCR01.01.04 | Identify the safety precautions associated with building materials. | |||

| ACCR01.01.05 | Describe the proper method of storing and handling building materials. | |||

| ACCR01.01.06 | State the uses of various types of engineered lumber. | |||

| ACCR01.01.07 | Calculate the quantities of lumber and wood products using square foot and lineal board foot. | |||

| ACCR01.01.08 | Describe the fasteners, anchors, and adhesives used in construction work and explain their uses. | |||

| ACCR01.01.09 | Explain the terms commonly used in discussing wood and lumber. | |||

| ACCR01.01.10 | Identify various types of imperfections that are found in lumber. | |||

| ACCR01.01.11 | Explain how plywood is manufactured, graded, and used. | |||

| ACCR01.01.12 | Identify various types of building boards and identify their uses. | |||

| ACCR01.01.13 | Identify the uses of and safety precautions associated with pressure-treated and fire-retardant lumber. | |||

| ACCR02 | Read plans and elevations. | ACCR02.01.01 | Describe the types of drawings usually included in a set of plans and list the information found on each type. | |

| ACCR02.01.02 | Identify the different types of lines used on construction drawings. | |||

| ACCR02.01.03 | Identify selected architectural symbols commonly used to represent materials on plans. | |||

| ACCR02.01.04 | Identify selected electrical, mechanical, and plumbing symbols commonly used on plans. | |||

| ACCR02.01.05 | Identify selected abbreviations commonly used on plans. | |||

| ACCR02.01.06 | Read and interpret plans, elevations, schedules, sections, and details contained in basic construction drawings. | |||

| ACCR02.01.07 | State the purpose of written specifications. | |||

| ACCR02.01.08 | Identify and describe the parts of a specification. | |||

| ACCR02.01.09 | Demonstrate or describe how to perform a quantity takeoff for materials. | |||

| ACCR03 | Identify and install floor systems. | ACCR03.01.01 | Identify different types of floor systems. | |

| ACCR03.01.02 | Explain the purpose of working drawings as they relate to flooring systems. | |||

| ACCR03.01.03 | Read and interpret drawings and specifications to determine floor system requirements. | |||

| ACCR03.01.04 | Identify floor and sill framing and support members. | |||

| ACCR03.01.05 | Name the methods used to fasten sills to the foundation. | |||

| ACCR03.01.06 | Given specific floor load and span data, select the proper girder/beam size from a list of available girders/beams. | |||

| ACCR03.01.07 | List and recognize different types of floor joists. | |||

| ACCR03.01.08 | Given specific floor load and span data, select the proper joist size from a list of available joists. | |||

| ACCR03.01.09 | List and recognize different types of bridging. | |||

| ACCR03.01.10 | List and recognize different types of flooring materials. | |||

| ACCR03.01.11 | Explain the purposes of subflooring and underlayment. | |||

| ACCR03.01.12 | Match selected fasteners used in floor framing to their correct uses. | |||

| ACCR03.01.13 | Estimate the amount of material needed to frame a floor assembly. | |||

| ACCR03.01.14 | Demonstrate the ability to lay out and construct a floor assembly | |||

| ACCR03.01.15 | Demonstrate the ability to install joists for a cantilever floor. | |||

| ACCR03.01.16 | Demonstrate the ability to install a subfloor using butt-joint plywood/OSB panels. | |||

| ACCR03.01.17 | Demonstrate the ability to install a single floor system using tongue-and-groove plywood/OSB panels. | |||

| ACCR04 | Indentify and install wall and ceiling framing. | ACCR04.01.01 | Identify the components of a wall and ceiling layout. | |

| ACCR04.01.02 | Describe the procedure for laying out a wood frame wall, including plates, corner posts, door and window openings, partition Ts, bracing, and firestops. | |||

| ACCR04.01.03 | Explain the different types of wall systems. | |||

| ACCR04.01.04 | Describe the correct procedure for assembling and erecting an exterior wall. | |||

| ACCR04.01.05 | Identify the common materials and methods used for installing sheathing on walls. | |||

| ACCR04.01.06 | Lay out, assemble, erect, and brace exterior walls for a frame building. | |||

| ACCR04.01.07 | Explain the use of metal studs in wall framing. | |||

| ACCR04.01.08 | Describe the correct procedure for laying out ceiling joists. | |||

| ACCR04.01.09 | Cut and install ceiling joists on a wood frame building. | |||

| ACCR04.01.10 | Estimate the materials required to frame walls and ceilings. | |||

| ACCR04.01.11 | Explain the different types of wall finishes. | |||

| ACCR04.01.12 | Demonstrate the ability to install paneling with wainscoting. | |||

| ACCR04.01.13 | Describe the process used in forming and installing tilt-up wall panels. | |||

| ACCR04.01.14 | Demonstrate the ability to build penetration firewalls and sound control walls per specifications. | |||

| ACCR05 | Identify and install roof framing and roofing. | ACCR05.01.01 | Understand the terms associated with roof framing. | |

| ACCR05.01.02 | Identify the roof framing members used in gable and hip roofs. | |||

| ACCR05.01.03 | Identify the methods used to calculate the length of a rafter. | |||

| ACCR05.01.04 | Identify the various types of trusses used in roof framing. | |||

| ACCR05.01.05 | Use a rafter framing square, speed square, and calculator in laying out a roof. | |||

| ACCR05.01.06 | Identify various types of sheathing used in roof construction. | |||

| ACCR05.01.07 | Frame a gable roof with vent openings. | |||

| ACCR05.01.08 | Frame a roof opening. | |||

| ACCR05.01.09 | Erect a gable roof using trusses. | |||

| ACCR05.01.10 | Estimate the materials used in framing and sheathing a roof. | |||

| ACCR05.01.11 | Identify the materials and methods used in roofing. | |||

| ACCR05.01.12 | Explain the safety requirements for roof jobs. | |||

| ACCR05.01.13 | Install fiberglass shingles on gable and hip roofs. | |||

| ACCR05.01.14 | Close up a valley using fiberglass shingles. | |||

| ACCR05.01.15 | Explain how to make various roof projections watertight when using fiberglass shingles. | |||

| ACCR05.01.16 | Complete the proper cuts and install the main and hip ridge caps using fiberglass shingles. | |||

| ACCR05.01.17 | Lay out, cut, and install a cricket or saddle. | |||

| ACCR05.01.18 | Demonstrate the techniques for installing other selected types of roofing materials. | |||

| ACCR05.01.19 | Describe the characteristics and properties of metals as they relate to roofing applications. | |||

| ACCR06 | Install concrete reinforcing materials and forms. | ACCR06.01.01 | Identify types of concrete reinforcement materials and describe their uses. | |

| ACCR06.01.02 | Identify various types of footings and explain their uses. | |||

| ACCR06.01.03 | Identify the parts of various types of forms. | |||

| ACCR06.01.04 | Explain the safety procedures associated with the construction and use of concrete forms. | |||

| ACCR06.01.05 | Erect, plumb, and brace a variety of concrete forms. | |||

| ACCR06.01.06 | Describe the applications of reinforcing bars, the uses of reinforced structural concrete, and the basic processes involved in placing reinforcing bars. | |||

| ACCR06.01.07 | Identify types of reinforcement bar supports and describe their uses. | |||

| ACCR06.01.08 | Identify types of welded-wire fabric (WWF) reinforcement material and describe their uses. | |||

| ACCR06.01.09 | Recognize and identify the bar bends standardized by the American Concrete Institute (ACI). | |||

| ACCR06.01.10 | Read and interpret bar lists and describe the information found on a bar list. | |||

| ACCR06.01.11 | List the types of ties used in securing reinforcing bars. | |||

| ACCR06.01.12 | State the tolerances allowed in the fabrication of reinforcing bars. | |||

| ACCR06.01.13 | Demonstrate the proper use of common ties for reinforcing bars. | |||

| ACCR06.01.14 | Describe methods by which reinforcing bars may be cut and bent in the field. | |||

| ACCR06.01.15 | Use the tools and equipment needed for installing reinforcing bars. | |||

| ACCR06.01.16 | Demonstrate the ability to safely use selected tools and equipment to cut, bend, and install reinforcing materials. | |||

| ACCR06.01.17 | Explain the necessity of concrete cover in placing reinforcing bars. | |||

| ACCR06.01.18 | Explain and demonstrate how to place bars in walls, columns, beams, girders, joists, and slabs. | |||

| ACCR06.01.19 | Identify lapped and welded splices. | |||

| ACCR06.01.20 | Recognize various types of manufactured forms. | |||

| ACCR06.01.21 | Identify the components of manufactured wall-forming systems. | |||

| ACCR06.01.22 | State the differences in construction and use among different types of forms. | |||

| ACCR06.01.23 | Describe how a flying form system is moved. | |||

| ACCR06.01.24 | Erect, plumb, and brace a manufactured wall form. | |||

| ACCR06.01.25 | Use a manufactured hardware system to erect forms of lumber and sheathing. | |||

| ACCR07 | Install windows and exterior doors. | ACCR07.01.01 | Identify various types of fixed, sliding, and swinging windows. | |

| ACCR07.01.02 | Identify the parts of a window installation. | |||

| ACCR07.01.03 | State the requirements for a proper window installation. | |||

| ACCR07.01.04 | Install a pre-hung window. | |||

| ACCR07.01.05 | Identify the common types of exterior doors and explain how they are constructed. | |||

| ACCR07.01.06 | Identify the parts of a door installation. | |||

| ACCR07.01.07 | Identify the types of thresholds used with exterior doors. | |||

| ACCR07.01.08 | Install a pre-hung exterior door. | |||

| ACCR07.01.09 | Identify the various types of locksets used on exterior doors and explain how they areinstalled. | |||

| ACCR07.01.10 | Install a lockset. | |||

| ACCR08 | Complete basic stair layout and construction. | ACCR08.01.01 | Identify the various types of stairs. | |

| ACCR08.01.02 | Identify the various parts of stairs. | |||

| ACCR08.01.03 | Identify the materials used in the construction of stairs. | |||

| ACCR08.01.04 | Interpret construction drawings of stairs. | |||

| ACCR08.01.05 | Calculate the total rise, number and size of risers, and number and size of treads required for a stairway. | |||

| ACCR08.01.06 | Lay out and cut stringers, risers, and treads. | |||

| ACCR08.01.07 | Build a small stair unit with a temporary handrail. | |||

| ACCR08.01.08 | Explain the methods of constructing various types of stairs. | |||

| ACCR08.01.09 | Understand the various terms and definitions relating to stairs. | |||

| ACCR08.01.10 | Lay out a skirt board. | |||

| ACCR08.01.11 | Explain and demonstrate the procedure for cutting and installing various stair parts (i.e. mitered finish stringers, mitered risers, treads, newel posts, handrails, and balusters.) | |||

| ACCR08.01.12 | Demonstrate the method for finishing service stairs and main stairs. | |||

| ACCR08.01.13 | Identify what materials can be used to build stairs for commercial construction. | |||

| ACCR09 | Conduct distance measurement and leveling for site layout. | ACCR09.01.01 | Describe the major responsibilities of the carpenter relative to site layout. | |

| ACCR09.01.02 | Convert measurements stated in feet and inches to equivalent measurements stated in decimal feet, and vice versa. | |||

| ACCR09.01.03 | Recognize, use, and properly care for tools and equipment associated with differential leveling. | |||

| ACCR09.01.04 | Use a builder’s level or transit and differential leveling procedures to determine site and building elevations. | |||

| ACCR09.01.05 | Record site layout data and information in field notes using accepted practices. | |||

| ACCR09.01.06 | Check and/or establish 90°angles using the 3/4/5 rule. | |||

| ACCR09.01.07 | Use the Pythagorean theorem to determine unknown values in site layout. | |||

| ACCR09.01.08 | Use right triangle trigonometry to determine unknown values in site layout. | |||

| ACCR09.01.09 | Convert angular measurements stated in decimal degrees to degrees, minutes, seconds and vice versa. | |||

| ACCR09.01.10 | Convert azimuth to bearing, and vice versa. | |||

| ACCR09.01.11 | Convert polar coordinates to rectangular coordinates, and vice versa. | |||

| ACCR09.01.12 | Convert distance and direction into latitudes and departures. | |||

| ACCR09.01.13 | Lay out building lines using traditional and radial layout techniques. | |||

| ACCR09.01.14 | Use a laser level to determine unknown elevations. | |||

| ACCR09.01.15 | Use trigonometric leveling techniques to determine unknown elevations. | |||

| ACCR10 | Describe properties and testing methods for concrete. | ACCR10.01.01 | Identify the properties of cement. | |

| ACCR10.01.02 | Describe the composition of concrete. | |||

| ACCR10.01.03 | Identify various types of cement and describe their uses. | |||

| ACCR10.01.04 | Identify types and sizes of concrete aggregates. | |||

| ACCR10.01.05 | Identify types of concrete admixtures and describe their uses. | |||

| ACCR10.01.06 | Identify special types of concrete and describe their uses. | |||

| ACCR10.01.07 | Identify concrete curing methods and materials. | |||

| ACCR10.01.08 | Identify concrete testing methods. | |||

| ACCR10.01.09 | Demonstrate sampling methods used for the testing of concrete. | |||

| ACCR10.01.10 | Perform slump testing of concrete. | |||

| ACCR10.01.11 | Perform casting of specimens for strength testing of concrete. | |||

| ACCR10.01.12 | Perform volume estimates for concrete quantity requirements. | |||

| ACCR11 | Prepare foundations and flatwork. | ACCR11.01.01 | Identify various kinds of footings (i.e. continuous or spread, stepped, pier, and grade beam) | |

| ACCR11.01.02 | Identify the parts of footing forms and explain their purpose. | |||

| ACCR11.01.03 | Identify the parts of pier forms and explain their purpose. | |||

| ACCR11.01.04 | Demonstrate the ability to lay out and construct selected footing forms (i.e. continuous, pier, pile cap, and grade beam). | |||

| ACCR11.01.05 | Strip a pier footing form and prepare it for erection at another location. | |||

| ACCR11.01.06 | Identify types of concrete structures that require the construction of edge forms such as slabs, parking lots, driveways, streets, sidewalks, and approaches. | |||

| ACCR11.01.07 | Identify the parts of edge forms and explain their purpose. | |||

| ACCR11.01.08 | Demonstrate the ability to construct and disassemble edge forms for a slab-on-grade with an existing or integral foundation. | |||

| ACCR11.01.09 | Explain the purpose of a screed and identify the different types of screeds. | |||

| ACCR11.01.10 | Demonstrate the ability to set screeds on grade. | |||

| ACCR12 | Handle and place concrete. | ACCR12.01.01 | Identify and state the purpose of different types of concrete joints. | |

| ACCR12.01.02 | Recognize the various equipment used to transport and place concrete. | |||

| ACCR12.01.03 | Describe the factors that contribute to the quality of concrete placement. | |||

| ACCR12.01.04 | Demonstrate and/or describe the correct methods for placing and consolidating concrete into forms. | |||

| ACCR12.01.05 | Demonstrate and/or describe how to use a screed to strike off and level concrete to the proper grade in a form. | |||

| ACCR12.01.06 | Demonstrate and/or describe how to use a bullfloat and/or darby to level and smooth concrete. | |||

| ACCR12.01.07 | Determine when conditions permit the concrete finishing operation to start. | |||

| ACCR12.01.08 | Demonstrate and/or describe how to use a hand float and finishing trowel. | |||

| ACCR12.01.09 | Demonstrate and/or describe how to use an edger. | |||

| ACCR12.01.10 | Demonstrate and/or describe how to use a jointer. | |||

| ACCR12.01.11 | Name the factors that affect the curing of concrete and describe the methods used to achieve proper curing. | |||

| ACCR12.01.12 | Properly care for and safely use hand and power tools used when working with concrete. | |||

| ACCR13 | Install exterior finishing. | ACCR13.01.01 | Describe the purpose of wall insulation and flashing. | |

| ACCR13.01.02 | Demonstrate lap and panel siding estimating methods. | |||

| ACCR13.01.03 | Describe the types and applications of common wood siding: | |||

| ACCR13.01.04 | Install selected types of wood siding. | |||

| ACCR13.01.05 | Describe fiber-cement siding and its uses. | |||

| ACCR13.01.06 | Demonstrate the installation of fiber-cement siding. | |||

| ACCR13.01.07 | Describe the types and applications of stucco and masonry veneer finishes. | |||

| ACCR13.01.08 | Describe the types and applications of special exterior finish systems. | |||

| ACCR13.01.09 | Describe the types and styles of gutters and downspouts and their accessories. | |||

| ACCR13.01.10 | Install selected types of metal or vinyl gutters and downspouts. | |||

| ACCR14 | Install thermal and moisture protection. | ACCR14.01.01 | Describe the requirements for insulation. | |

| ACCR14.01.02 | Describe the characteristics of various types of insulation material. | |||

| ACCR14.01.03 | Calculate the required amounts of insulation for a structure. | |||

| ACCR14.01.04 | Demonstrate the installation of selected insulation materials. | |||

| ACCR14.01.05 | Describe the requirements for moisture control and ventilation. | |||

| ACCR14.01.06 | Install selected vapor barriers. | |||

| ACCR14.01.07 | Describe various methods of waterproofing. | |||

| ACCR14.01.08 | Describe air infiltration control requirements. | |||

| ACCR14.01.09 | Install selected building wraps. | |||

| ACCR15 | Install and finish drywall. | ACCR15.01.01 | Identify the different types of gypsum wallboard (drywall) and their uses. | |

| ACCR15.01.02 | Select the type and thickness of drywall required for specific installations. | |||

| ACCR15.01.03 | Select fasteners for drywall installation. | |||

| ACCR15.01.04 | Explain the fastener schedules for different types of drywall installations. | |||

| ACCR15.01.05 | Perform single-layer and multi-layer drywall installations using different types of fastening systems. | |||

| ACCR15.01.06 | Install gypsum drywall on metal studs. | |||

| ACCR15.01.07 | Explain how soundproofing is achieved in drywall installations. | |||

| ACCR15.01.08 | Estimate material quantities for a drywall installation. | |||

| ACCR15.01.09 | Explain the different levels of finishing as recognized by the industry. | |||

| ACCR15.01.10 | Identify the hand tools used in drywall finishing and demonstrate the ability to use these tools. | |||

| ACCR15.01.11 | Identify the automatic tools used in drywall finishing. | |||

| ACCR15.01.12 | Identify the materials used in drywall finishing and state the purpose and use of each type of material, | |||

| ACCR15.01.13 | Demonstrate the ability to properly finish drywall using hand tools. | |||

| ACCR15.01.14 | Recognize various types of problems that occur in drywall finishes and identify the cause and correct method for solving each type of problem. | |||

| ACCR15.01.15 | Demonstrate the ability to patch damaged drywall. | |||

| ACCR16 | Install interior doors. | ACCR16.01.01 | Identify various types of door jambs and frames and demonstrate the installation procedures for placing | |

| ACCR16.01.02 | Selected door jambs and frames in different types of interior partitions. | |||

| ACCR16.01.03 | Identify different types of interior doors. | |||

| ACCR16.01.04 | Identify different types of interior door hardware and demonstrate the installation procedures for selected types. | |||

| ACCR16.01.05 | List and identify specific items included on a typical door schedule. | |||

| ACCR16.01.06 | Demonstrate the procedure for placing and hanging a selected door. | |||

| ACCR17 | Install interior trim. | ACCR17.01.01 | Identify the different types of standard moldings and describe their uses. | |

| ACCR17.01.02 | Make square and miter cuts using a miter box or power miter saw | |||

| ACCR17.01.03 | Make coped joint cuts using a coping saw | |||

| ACCR17.01.04 | Estimate the quantities of different trim materials required for selected rooms. | |||

| ACCR17.01.05 | Select and properly use fasteners to install trim | |||

| ACCR17.01.06 | Install different types of interior trim. | |||

| ACCR18 | Install cabinets. | ACCR18.01.01 | State the classes and sizes of typical base and wall kitchen cabinets. | |

| ACCR18.01.02 | Recognize the common types of woods used to make cabinets. | |||

| ACCR18.01.03 | Install factory-made cabinets, countertops, and backsplashes. | |||

| ACCR18.01.04 | Install plastic laminate on a countertop core. | |||

| ACCR18.01.05 | Identify cabinet components and hardware and describe their purpose. | |||

| ACCR18.01.06 | Identify and cut the various types of joints used in cabinetmaking. | |||

| ACCR18.01.07 | Build a cabinet from a set of drawings. | |||

| Architecture & Construction Cluster-- Construction Management Focus Area | ||||

| Common Career Technical Core Standards (CCTC) - National | ||||

| CCTC Number | OSSA Code | Knowledge & Skills Standards | Performance Indicator Codes | Performance Indicators - Standards |

| AC-CST 1 | ACCS01 | Understand contractual relationships with all parties involved in the building process to ensure successful build of a project. | ACCS01.01.01 | Establish/implement reporting relationships among stakeholders. |

| ACCS01.02.01 | Create sustainable and accountable partnerships between stakeholders. | |||

| ACCS01.03.01 | Describe the contracting process to include contract development, the bid process, payment terms, planning approvals, and limitations of liability. | |||

| ACCS01.04.01 | Describe the role that each stakeholder will assume to ensure successful completion of the project. | |||

| AC-CST 2 | ACCS02 | Understand approval procedures to ensure effective flow of information in the construction process. | ACCS02.01.01 | Identify the components necessary for developing submittal approval procedures system. |

| ACCS02.02.01 | Employ procedures that complete submittal approval process related to shop drawings. | |||

| ACCS02.03.01 | Employ procedures that complete submittal approval process related to state and local permits. | |||

| AC-CST 3 | ACCS03 | Understand and implement testing and inspection procedures to ensure successful completion of a construction project. | ACCS03.01.01 | List testing and inspection procedures related to specific areas. |

| ACCS03.02.01 | Interpret guides designed for testing and inspection purposes in specific areas. | |||

| ACCS03.03.01 | Explain the benefits of using an external contractor to conduct the testing and inspection on the different phases of a build project. | |||

| AC-CST 4 | ACCS04 | Understand the purpose of scheduling as it relates to the successful completion of a construction project. | ACCS04.01.01 | Develop a schedule for a specific project. |

| ACCS04.02.01 | Explain rationale for a specific scheduling procedure. | |||

| ACCS04.03.01 | Describe the relationship between scheduling, risk assessment, and cost estimating to the success of the project | |||

| AC-CST 5 | ACCS05 | Understand and apply practices and procedures required to maintain jobsite safety. | ACCS05.01.01 | Determine procedures for a jobsite safety program. |

| ACCS05.02.01 | Incorporate the procedures into the design of a safety program. | |||

| ACCS05.03.01 | Identify universal signs and symbols, such as colors, flags, stakes, and hand signals that apply to construction worksite situations. | |||

| ACCS05.03.02 | Explain functions of signs and symbols. | |||

| ACCS05.03.03 | Inspect all signs and symbols for safe and proper use. | |||

| ACCS05.04.01 | Explain the need for jobsite security to prevent liability | |||

| ACCS05.05.01 | Determine the components necessary to ensure environmental safety on the jobsite. | |||

| AC-CST 6 | ACCS06 | Manage relationships with internal and external parties to successfully complete construction projects. | ACCS06.01.01 | Describe strategies used to promote collaboration, trust, and clear communication among contractors, suppliers, clients, and others on a jobsite. |

| AC-CST 7 | ACCS07 | Compare and contrast the building systems and components for a given project. | ACCS07.01.01 | Identify building systems needed to complete a construction project. |

| ACCS07.01.02 | List all building systems involved in a project. | |||

| ACCS07.01.03 | Describe the purpose of each system. | |||

| ACCS07.01.04 | List all components of the involved building system. | |||

| ACCS07.01.05 | Describe the function of each component. | |||

| ACCS07.02.01 | Identify components of building systems needed to complete a construction project. | |||

| ACCS07.03.01 | Incorporate appropriate building systems into a construction project. | |||

| AC-CST 8 | ACCS08 | Demonstrate the construction crafts required for each phase of a given project. | ACCS08.01.01 | Utilize skills to maintain tools, machinery, equipment, and construction resources. |

| AC-CST 9 | ACCS09 | Safely use and maintain appropriate tools, machinery, equipment, and resources to accomplish construction project goals. | ACCS09.01.01 | Select tools, machinery, equipment, and supplies that match project requirements. |

| ACCS09.01.02 | Use tools, machinery, and equipment according to industry standards. | |||

| ACCS09.01.03 | Properly maintain tools, machines, and equipment in a safe manner. | |||

| ACCS09.02.01 | Identify sources of information about state-of-the-art tools, machinery, equipment, materials, construction technologies. | |||

| ACCS09.03.01 | Demonstrate use of tools, machinery, equipment, and other resources commonly used in design and construction. | |||

no reviews yet

Please Login to review.