218x Filetype DOCX File size 0.02 MB Source: imlive.s3.amazonaws.com

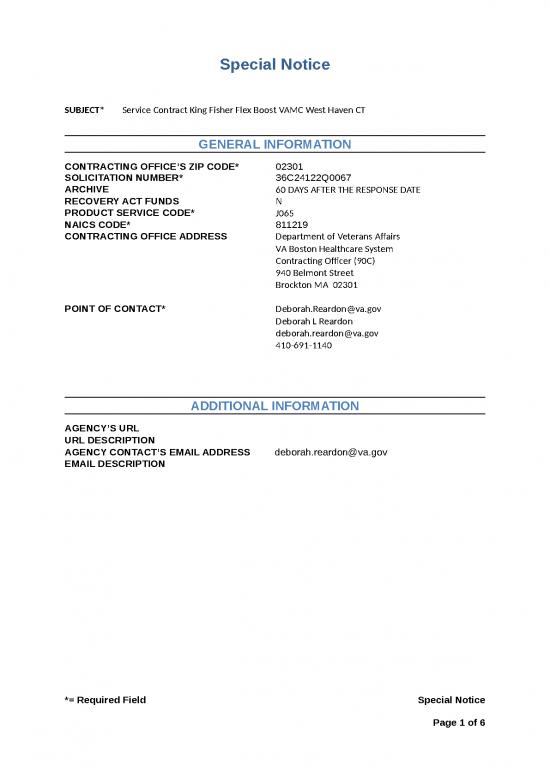

Special Notice

SUBJECT* Service Contract King Fisher Flex Boost VAMC West Haven CT

GENERAL INFORMATION

CONTRACTING OFFICE’S ZIP CODE* 02301

SOLICITATION NUMBER* 36C24122Q0067

ARCHIVE 60 DAYS AFTER THE RESPONSE DATE

RECOVERY ACT FUNDS N

PRODUCT SERVICE CODE* J065

NAICS CODE* 811219

CONTRACTING OFFICE ADDRESS Department of Veterans Affairs

VA Boston Healthcare System

Contracting Officer (90C)

940 Belmont Street

Brockton MA 02301

POINT OF CONTACT* Deborah.Reardon@va.gov

Deborah L Reardon

deborah.reardon@va.gov

410-691-1140

ADDITIONAL INFORMATION

AGENCY’S URL

URL DESCRIPTION

AGENCY CONTACT’S EMAIL ADDRESS deborah.reardon@va.gov

EMAIL DESCRIPTION

*= Required Field Special Notice

Page 1 of 6

Special Notice

DESCRIPTION

Veterans’ Health Affairs, Network Contracting Office 1, is issuing this Notice of Intent to Sole Source in order

to identify any potential sources that have the resources and capabilities to provide a service agreement for

King Fisher Flex Boost Unit’s as described below and will not interrupt the continuum of care . This

requirement is defined by an existing unit currently in use at the West Haven VAMC.

ALL RESPONSES TO THIS INTENT TO SOLE SOURCE ARE DUE 11/9/2021 2:00 PM EST.

This notice of intent is not a request for competitive proposals. Any responsible sources that

wish to identify their interest and capability to provide this equipment or equipment that is

compatible must notify this Contracting Officer at Deborah.reardon@va.gov NLT 2:00PM EST,

Friday, November 9, 2021. Telephone responses will not be accepted. Upon receipt of the

interested parties' notification, the Contracting Officer will determine whether to conduct a

competitive procurement or proceed with sole source negotiations.

Special Notice

Page 2 of 6

Special Notice

Statement of Work (SOW)

AB Assurance 1PM Service Agreement Plan

VACT, 950 Campbell Ave. West Haven, CT 06516

1.0 Introduction (Provide a brief description of what you are buying).

Type of Contract: Firm Fixed Price Service Contract(s)

Contract Performance Period: One year

Contract Transaction Number: 689-22-1-7441-0003

2.0 Background (Provide any historical information necessary to understand how and why the requirement

evolved and where it is headed. Include appropriate information to help the reader/contractor

understand the requirement).

The service agreement is necessary to ensure the units remain in a safe, working condition for COVID 19 testing.

The KingFisher Flex units boost the lab's productivity by reducing hands-on sample preparation time, reducing

costs, and increasing throughput. Intuitive to operate and pre-loaded with protocols, the KingFisher Flex system

offers automated magnetic bead-based sample preparation for DNA and RNA. Effective bead collection and transfer

leads to superior washing, efficient elution, and rapid processing, delivering reliable high recovery and consistent

performance across a range of complex samples.

3.0 Scope (Provide an overview of the PWS emphasizing the most important aspects of your requirement

and defining the boundaries of the contractor’s performance responsibilities).

Item No. Description Qty Price

1.) KingFisher Flex, 96 DW 1 TBD

Unit SN:711-82678

2.) KingFisher Flex, 96 DW 1 TBD

Unit SN:711-82689

4.0 Applicable Directives (List all documents referenced in the next section 5.0, Performance Requirements,

with which the contractor will have to comply in performance of the contract effort. If only portions of a

given document apply, specifically identify the applicable portions).

4.1 Contractors, contractor personnel, subcontractors, and subcontractor personnel shall be subject to

the same Federal laws, regulations, standards, and VA Directives and Handbooks as VA and VA

personnel regarding information and information system security.

4.2 Contractor shall not need to access VA Information systems

4.3 All contractors, subcontractors, and third-party servicers and associates working with VA information

are subject to the same investigative requirements as those of VA appointees or employees who have access to the

same types of information. The level and process of background security investigations for contractors must be in

accordance with VA Directive and Handbook 0710, Personnel Suitability and Security Program. The Office for

Operations, Security, and Preparedness is responsible for these policies and procedures. This unit(s) does not require

Special Notice

Page 3 of 6

Special Notice

use or storage of PHI or sensitive information, due to such, "The A&A requirements do not apply, and that a Security

Accreditation Package is not required.

5.0 Performance Requirements (Identify what the contractor is required to do (major tasks and subtasks).

Onsite Priority Response - is an important feature of our AB Assurance service plan. Customers receive

guaranteed 2 business day priority on-site response. In addition, Life Technologies engineers are required to

provide a 4-hr phone response when dispatched to a service request.

Planned Maintenance visit - A planned maintenance procedure includes verification of thermal cycler block

temperature uniformity/accuracy, cycle performance, heated cover accuracy, and optical calibrations. With the

AB Assurance service plan, annual planned maintenance (PM) visit is automatically opened and will be

performed within the contract period. Should you have an immediate need to request and/or schedule your PM,

please contact our Instrument Care Center at 800-955-6288 option 3,1 or email them at

Instrumentservices@lifetech.com to schedule. This PM visit ensures optimal performance of your instrument,

often preventing major breakdowns before they happen.

Spectral Dye Calibration during the PM - Performed during the planned maintenance visit. Includes labor and

Kit for (1) block. Calibrations on additional blocks can be purchased at an additional charge. Calibration

involves analysis of signal strength from standard pure dyes to adjust software for correct data output (for Real

Time PCR Instruments only)

Includes:

o Dyes

o Certification documentation

o Certificate of Calibration

Labor & Travel Fees covered at 100% - All labor and travel fees are included for repair and planned

maintenance.

Replacement Parts covered at 100% - All parts are certified and guaranteed to optimize instruments

performance and reliability. All parts are manufactured by AB or AB’s direct vendors. Life Technologies uses

only new or true factory remanufactured parts.

Technical Assistance Center (TAC) is a service reserved for our contract and warranty customers. The service

gives you direct access to senior level service personnel for first-level problem resolutions. This provides

immediate response in resolving many operational and instrument set-up problems.

Remote Diagnostics is a service providing remote connectivity to your systems. This software, which is

exclusive to Life Technologies, provides email notifications to both end users and our Technical Assistance

Center of instrument conditions and errors. In doing so, it allows both your staff and Life Technologies to

perform pre-emptive service in order to maintain instrument uptime, which leads to higher sample throughput.

This service is reserved for our contract and warranty customers.

6.0 Deliverables (List all data required to manage or monitor contractor performance).

The documentation shall include detailed descriptions of the scheduled and unscheduled maintenance

(i.e., Emergency repairs) procedures performed, including replaced parts and prices (for outside normal

working hour services) required to maintain the equipment in accordance with Section 3, Conformance

Special Notice

Page 4 of 6

no reviews yet

Please Login to review.