233x Filetype PDF File size 0.31 MB Source: www.plm.automation.siemens.com

Opcenter Scheduling

SMT frequent, real-time changes that occur

in the manufacturing stage, especially

in high mix, low volume production or

when introducing a new product.

Opcenter Scheduling SMT, which is part

Providing realistic work-order scheduling based of Xcelerator, the comprehensive and

on factory capacity and configuration integrated portfolio of software and

services from Siemens Digital Industries

Software, combines data from three

sources: (1) machine, line

Benefits Summary configurations and resource availability

• Facilitates intelligent SMT line Opcenter™ Scheduling SMT software is from the shop floor, (2) work orders,

grouping to optimize productivity a planning and scheduling tool for the schedules and work hours from the

by minimizing machine setup electronics manufacturing industry that enterprise resource planning (ERP)

when manufacturing multiple seamlessly connects the planner to the system and (3) material availability and

products shop floor. Opcenter Scheduling SMT location from the supply chain. The

• Provides full flow coverage, includ- supports factory planners as they combination of the three enables

ing SMT, test, manual and generate production schedules while accurate short-term scheduling while

assembly/box build adhering to a dynamic manufacturing creating a production plan that includes

environment and taking into account groups per line, static feeder settings,

• Uses what-if simulation to enable

immediate response to line-down

scenarios

• Delivers long-term planning,

capacity forecasting and assistance

in new equipment investments, to

help mitigate risk

• Provides actual versus scheduled

real-time performance analysis for

a rapid response to bottlenecks

• Includes realistic SMT production

scheduling based on actual factory

capacity

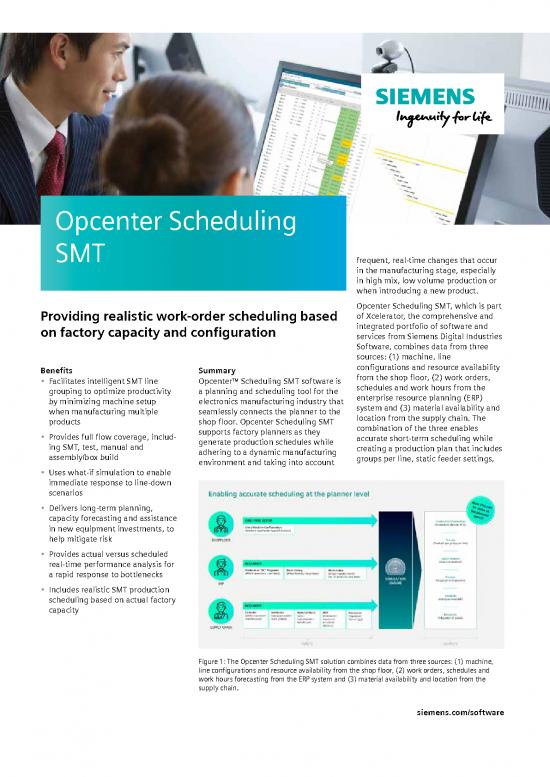

Figure 1: The Opcenter Scheduling SMT solution combines data from three sources: (1) machine,

line configurations and resource availability from the shop floor, (2) work orders, schedules and

work hours forecasting from the ERP system and (3) material availability and location from the

supply chain.

siemens.com/software

OPCENTER

Opcenter Scheduling SMT

trolley usage, kanban/work-in-process information from Opcenter APS and

(WIP) and resource allocation. update the schedule.

Combining intuitive constraint

definition with tight SAP integration Intuitive, easy-to-use production

makes Opcenter Scheduling SMT an scheduling

efficient, easy-to-use, decision- Set up your constraints using a simple

supporting tool that dramatically yet comprehensive model that allows

improves manufacturing efficiency and you to quickly set up all surface mount

supports compliance. Opcenter technology (SMT) and manual stations

Scheduling SMT can be integrated with in your factory as a basis for conducting

Opcenter Advanced Planning and simulation. You can easily control

Scheduling (APS). When integrated, it optimization parameters, such as due

can read work order and calendar dates, production time and

Schedule 1

Schedule 2

Schedule 1

Schedule 2

Figure 2: You can easily control optimization parameters such as due dates, production time and changeovers and then compare scenarios.

OPCENTER

Figure 3: Easily generate the optimal product groups using Opcenter Scheduling SMT to maximize efficiency.

change-overs, and then compare the factory by exporting a calendar file

different scenarios. You can then for monitoring and visibility.

choose the schedule that best fits your

needs. What-if scenarios to optimize

Effective tool to help meet deadlines schedules

and avoid downtime You can easily make on-the-fly

React to changes quickly using actual optimizations based on different

versus scheduled performance tracking, scenarios (for example, adding

allowing you to detect potential unscheduled work orders, missing

bottlenecks and avoid downtime. You resources such as feeders or late

can also import shift schedules or add material arrival) to support the planner’s

additional lines to see how such decision-making process. Additional

changes affect your ability to meet what-if scenarios can be made based on

deadlines. You can update schedules, scheduled material arrival and material

for example, adding shifts or controlling location data, which can be imported

the number of active lines to analyze via integration with SAP and Valor™

their impact on due-date violations. Material Management software.

Your schedule can then be shared with

OPCENTER

Siemens web services

Figure 4: When integrated with SAP, Opcenter Scheduling SMT saves the time and effort typically required to develop a custom interface.

Multi-line work order and product stock levels from SAP ERP by simply

grouping configuring the location and parameters

Opcenter Scheduling SMT can be used of your SAP Process Integration (PI)

to generate the optimal product groups module.

(family setups or clusters), taking into

consideration machine capacity, feeder You can also update the part reel

availability, work-order priority and quantities from SAP by selecting what

component range. to import and from where. Required

Quick to get started quantity levels for each part in the work

Opcenter Scheduling SMT offers built-in order can be displayed, along with

connectivity to a range of SMT inventory levels and the quantity

production solutions and to Valor™ remaining after the work orders are

Process Preparation software. This gets executed.

you started quickly and allows simple Optimized work-in-process (WIP)

daily workflows. system requirements

Seamless integration with SAP To avoid an excessive amount of WIP

Unlike generic manufacturing-schedul and subassemblies in different stages of

ing solutions, Opcenter Scheduling SMT manufacturing, Opcenter Scheduling

enables you to save the time and effort SMT can be used to generate an optimal

typically required to coordinate between SMT production schedule that meets

SAP and your scheduling process. You specified quantities in predefined

can extract work orders, required stages.

delivery dates, release data and material

no reviews yet

Please Login to review.