164x Filetype PDF File size 2.49 MB Source: www.scor.com

Technical

Newsletter

#34 - November 2016

PETROLEUM REFINING AND INSURANCE

PART I

Crude Oil Refining - a constantly evolving industry

Introduction

th

Refining can be considered by many as a mature and stable industry but it has changed drastically since the 19 century,

adapting to its ever-changing and challenging environment. Insurers have had to follow this transformation and adapt

their way of underwriting these risks.

Part I of this Technical Newsletter takes us on the journey the refining industry has had to travel.

In the beginning was the crude oil…

Of interest to refiners and insurers is that petroleum has been

known and used in various ways (adhesives, flaming projectiles, ”GET UP EARLY, WORK LATE - AND

boat coating, lighting...), since ancient times. The first users of STRIKE OIL.” JOHN D. ROCKEFELLER’S

petroleum were located in the Middle East (Egypt, Babylon,

Mesopotamia, Persia...) and China. RECIPE FOR SUCCESS.

Many types of crude oils are produced around the world.

The main components, primarily hydrocarbons, can be Sulfur and TAN(1) are good indicators of potential corrosion

differentiated by their properties, the most important of which problems and are therefore of interest to insurers.

is the boiling temperature as it allows for the primary separation

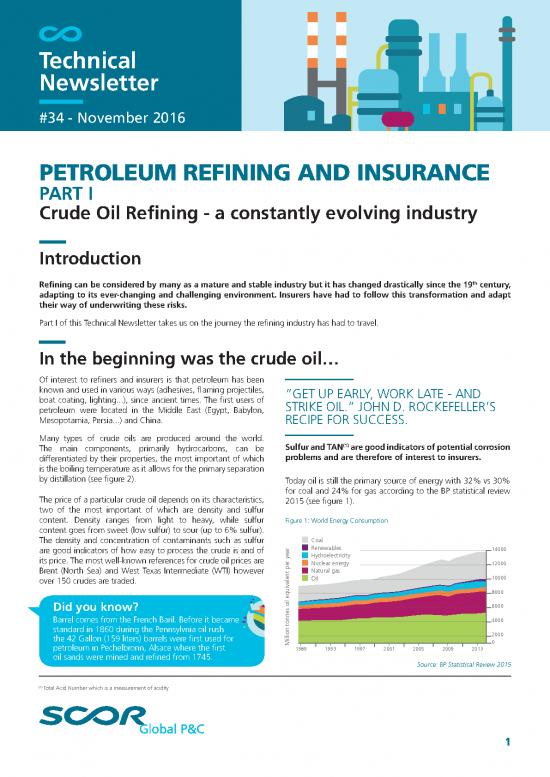

by distillation (see figure 2). Today oil is still the primary source of energy with 32% vs 30%

for coal and 24% for gas according to the BP statistical review

The price of a particular crude oil depends on its characteristics, 2015 (see figure 1).

two of the most important of which are density and sulfur

content. Density ranges from light to heavy, while sulfur Figure 1: World Energy Consumption

content goes from sweet (low sulfur) to sour (up to 6% sulfur).

Coal

The density and concentration of contaminants such as sulfur Coal

Renewables 14000

are good indicators of how easy to process the crude is and of Renewables 14000

Hydroelectricity

Hydroelectricity

its price. The most well-known references for crude oil prices are Nuclear energy 12000

Nuclear energy 12000

Natural gas

Brent (North Sea) and West Texas Intermediate (WTI) however Natural gas

Oil 10000

over 150 crudes are traded. Oil 10000

8000

8000

6000

Did you know? 6000

Barrel comes from the French Baril. Before it became 4000

4000

standard in 1860 during the Pennsylvnia oil rush

2000

the 42 Gallon (159 liters) barrels were first used for 2000

petroleum in Pechelbronn, Alsace where the first Million tonnes oil equivalent per year 0

1989 1993 1997 2001 2005 2009 2013

89 91 93 95 97 99 01 03 05 07 09 11 13 0

oil sands were mined and refined from 1745.

Source: BP Statistical Review 2015

(1)

Total Acid Number which is a measurement of acidity

1

Refining 1.01

A petroleum refinery is an industrial process plant where ”TURNAROUNDS AND OTHER

crude oil is processed into more useful products such as (by MAINTENANCE ACTIVITIES ARE

order of volumes produced): IMPORTANT FOR THE INTEGRITY OF THE

› Transportation fuels (gasoline, kerosene, diesel) PLANT AND THEREFORE OF PARTICULAR

› Heating fuels (fuel oil) INTEREST TO INSURERS.”

› Petrochemical industry feedstocks (naphtha, propylene)

› Liquefied Petroleum Gas (butane, propane) Due to the evolution of technology and automation, the

› Lubricants number of employees has decreased from several thousands, for

example the Whiting Refinery in the US employed 3000 people

› Bitumen in the early 1900’s, to a few hundred in developed countries

depending on the level of contracting. In some cases, the number

› Coke of employees could be higher, as it can be used by governments

› Sulfur as a means of employment. The skills of the employees have

significantly changed and the level of knowledge has increased

considerably.

Figure 2: Distillation of crude oil, Gas

first step of refining 20°C

150° C Finally, the complexity of refinery operations is such that they can

Gasoline be fully optimised to produce the highest possible margins, only

200° C through the use of Linear Programming (LP) models to respond

Kerosene to changes in market environment and to the introduction of

300° C new (usually more stringent) product specifications and new

Crude Oil Diesel crude slates.

370° C

Fuel Oil Refineries are composed of three main areas:

400° C

› PROCESS UNITS : where crude oil is actually transformed into

Lubricating Oil, final products.

Paraffin Wax,

FURNACE Asphalt › UTILITIES: produce all the utilities required by the process

Source: SCOR units such as power, steam, hydrogen, nitrogen, air, water…

Basically crude oil undergoes physical and chemical processes. › STORAGE (feedstocks and products): required to store the

Figure 3 shows a typical refinery process flow diagram with usual crude oil and final products before they are expedited.

process units and final products. By nature, hydrocarbons

are flammable products and they are processed at high

temperatures and pressures in the presence of hydrogen,

which exacerbates their flammability and explosivity.

Hence, the safe operation of refineries requires a broad

range of highly trained and specialised personnel

(instrumentation, electrical, mechanical, process, safety...).

Refinery capacity is defined by the crude throughput and is

generally expressed in barrels per day (bpd). Refineries operate

continuously, 24 hours a day, 365 days a year, except when they

are shut down for the general maintenance of the units known

as turnaround. These take place every 4 to 5 years, usually lasting

5 to 6 weeks, during which time maintenance activities that

cannot be performed during normal operations are carried out.

SCOR GLOBAL P&C - TECHNICAL NEWSLETTER #34 - NOVEMBER 2016

2

Figure 3: Refinery process flow diagram

Crude Oil

Tanker Pipeline

Gas Gas

Liquid Atmospheric

Distillation Distillation

Atmospheric Residue Kerosene Gas

Function:

Separates the

Sour GasSour Gas different products

Vacuum Naphtha Gas Steam based on boiling

Distillation Plant Reforming points

Examples:

Butane / PropaneFuel GasHH -Atmospheric

22 distillation

Vacuum Residue

-Vacuum distillation

Sour GasSour Gas

Distillates HDS Sour GasSour Gas

Treatment

Visbroken Gasoline Function:

Amine Removes the

Delayed Visbreaking MEROX contaminants such as

HDT Washing

Coker Sour GasSour Gas sulfur and nitrogen

HH Sour GasSour Gas from the feeds

22

Distillates Prepares streams for

additional processing

CokeLight Coker GasoilHeavy Coker GasoilCoker GasolineVisbroken ResidueVisbroken GasoilVisbroken Gasoline Examples:

2H -Distillate and

rich gas gasoline

hydrotreatments

HDS Naphtha Claus Unit/ (HDS, HDT)

HDS Splitter Tail Gas

Light Naphtha

Sour GasSour Gas

HH Heavy Naphtha

22

Light FCC Gasoil Upgrading

Function:

Rearranges the

molecules to

improve the

Catalytic properties of the

Hydrocraking Heavy Naphtha feed

Cracking FCC Examples:

-Catalytic reforming

Heavy FCC GasoilFCC GasolineButenesPropyleneGasoilKeroseneLight Naphtha -Alkylation

Catalytic -Isomerisation

Reforming Isomerisation

Butane / Propane

Lube Oil Conversion

Plant

Function:

Methanol / Ethanol Breaks down the

heavy crude

Isobutene fractions into lighter

Butane products, such as

middle distillate.

Sour GasSour Gas Examples:

HH

22 -Fluid Catalytic

Cracking (FCC)

-Hydrocracker

-Coker

HDT MTBE-ETBE Alkylation

Blending

Vacuum Residueacuum ResidueVAsphaltAsphaltLube Oils / Parafins / WCokeVisbroken ResidueHeavy FCC GasoilGasoilGasoil Kerosene FCC GasolineMTBE / ETBEAlkylateLight NaphthaReformateIsomeratePropyleneBenzeneNaphthaCommercial Butane / PropaneFuel GasSulfur

Function:

Mixes the various

hydrocarbon

components

manufactured in the

refinery to meet the

axes final product

specifications

Examples:

-Blending areas with

pumps and

intermediate storage

tanks.

Blending Lube Oil Blending / Blending / Blending / Blending /

Blending Tank Farm Tank Farm Tank Farm Tank Farm

Additives Additives Additives

Bitumen Waxes Coke Own Heavy Fuel Heating Diesel Kerosene Gasoline Petro- Liquefied Fuel Sulfur

Coke Parrafins Refinery /Bunker Oil chemicals Petroleum Gas

Lube Oils Fuel Gases Source: SCOR

SCOR GLOBAL P&C - TECHNICAL NEWSLETTER #34 - NOVEMBER 2016

3

The complexity of refining processes has been increasing

dramatically

The refinery process has been Table 1: From simple to complex refineries

improved over more than 100 years

with the addition of new, more CONFIGURATION NELSON DESCRIPTION

complex units. COMPLEXITY

INDEX

The Nelson Complexity Index

(NCI), which allows to measure the

conversion capacity in comparison to Topping < 2 This type of refinery simply separates crude oil into

the primary distillation capacity of any light gas, refinery fuel, naphtha and distillates (final

products) by atmospheric distillation. There are no

refinery, is used to compare refineries. chemical reactions involved.

It is an indicator of the investment

intensity or cost index of the refinery Hydroskimming 2-6 Upgrades naphtha into gasoline with catalytic

but also the potential value added of a reforming and removes sulfur with hydrotreating units.

refinery (see table 1).

Conversion 6-12 Converts heavy crude oil fractions (fuel oil, asphalt low

The trend of increasing conversion value product) into lighter products (such as gasoline

capability will pull up the complexity and diesel).

index as the world’s demand for lighter

products increases. Deep Conversion >12 Converts the heaviest and least valuable crude oil

fractions (residual oil) into lighter more valuable

The complexity index has increased products.

over the years (see figure 4).

A short history of the petroleum and refining industry

The modern history of petroleum started when James In 1870, the US were the largest oil exporter and J. D Rockefeller

Oakes discovered how to produce kerosene from coal in founded the Standard Oil Company which by 1879 controlled

1847 in England. 90% of US refining capacity.

In 1857, Michael Dietz invented a flat-wick kerosene lamp that The demand for petroleum was relatively stable until the early

th

replaced whale oil and created a new market for crude oil. 20 century. The invention of electricity progressively replaced

kerosene lamps. The invention of the automobile and its mass

The advancement of crude oil production began when Colonel production shifted the demand to gasoline and diesel.

Edwin L. Drake developed a new technology to extract oil from

the ground near Titusville, Pennsylvania, using drilling, with a

steam engine, through a pipe. The first drop of oil came out

from the ground when the well depth reached 69ft, on Monday Did you know?

th

29 August 1858, later producing 30 barrels per day. This

marked the beginning of the Pennsylvania oil rush. Colonel Drake was to end

The conjunction of those events triggered the oil and then the up as an impoverished man.

Pennsylvania voted an annuity

refining industry boom. In 1860-1861, seven refineries were of $1,500 to the “crazy

built in Pennsylvania and Arkansas. By the end of the 1860s, man” whose determination

58 refineries were in operation in Pittsburgh, primarily to recover founded the oil industry.

kerosene.

SCOR GLOBAL P&C - TECHNICAL NEWSLETTER #34 - NOVEMBER 2016

4

no reviews yet

Please Login to review.