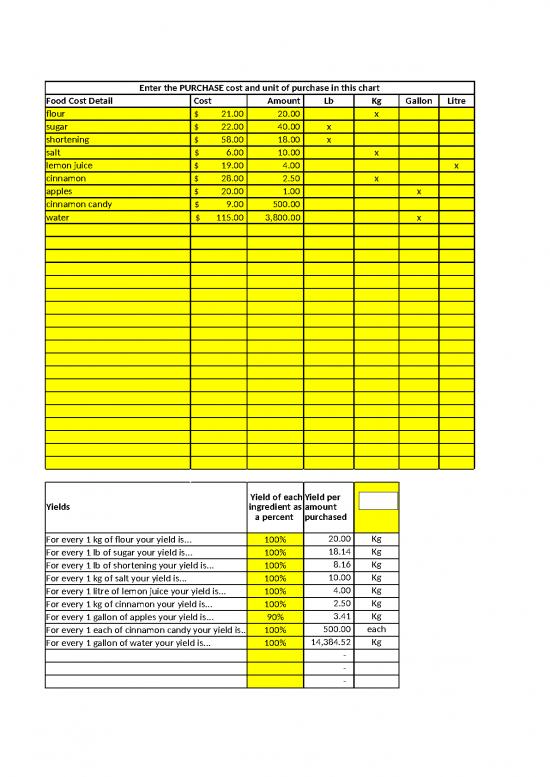

| Enter the PURCHASE cost and unit of purchase in this chart |

|

|

|

|

| Food Cost Detail |

Jeff Fidyk:

Enter the landed cost of each ingredient here.

Landed cost is the final cost of each ingredient including shipping/freight/delivery cost to get it to you.

Cost |

Jeff Fidyk:

If you purchase 425g of an item, enter 0.425 in the amount and select kg for units.

Similarly, if you purchase 6 oz of an item, you would enter =6/16 in the amount and select lb. There are 16 oz per lb.

If you purchase 678 ml of an item, enter 0.678 in the amount and select litre.

Amount |

Lb |

Kg |

Gallon |

Litre |

Jeff Fidyk:

The "Each" selection is application when you purchase an ingredient that is "by count" versus "by weight".

For example, you may purchase taco shells in cases of 120 units, rather than a weight amount.

Each |

|

|

|

| flour |

$21.00 |

20.00 |

|

x |

|

|

|

|

For all charts in this file, please only enter information as indicated in the YELLOW highlighted boxes. .................................... For the chart to the left, please use only "x" - lower case letter "x" to indicate the unit of measure for each ingredient. |

| sugar |

$22.00 |

40.00 |

x |

|

|

|

|

|

| shortening |

$58.00 |

18.00 |

x |

|

|

|

|

|

| salt |

$6.00 |

10.00 |

|

x |

|

|

|

|

| lemon juice |

$19.00 |

4.00 |

|

|

|

x |

|

|

| cinnamon |

$28.00 |

2.50 |

|

x |

|

|

|

|

| apples |

$20.00 |

1.00 |

|

|

x |

|

|

|

| cinnamon candy |

$9.00 |

500.00 |

|

|

|

|

x |

|

| water |

$115.00 |

3,800.00 |

|

|

x |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Yields |

Jeff Fidyk:

If you are wasting or cannot use all of your purchased ingredients, you should enter the amount that is usable in this column beside each ingredient.

For example, if you purchase apples, the entire apple typically cannot be used. You would need to peel and core the apples. The average weight of the apples after they have been peeled and cored divided by the total weight purchased would be entered here as a percentage or just enter: =usable weight/total weight purchased

Yield of each ingredient as a percent |

Jeff Fidyk:

This column just shows you the net weight per purchase amount that you have to use.

Yield per amount purchased |

Jeff Fidyk:

You can choose between Kg or Lb

|

|

|

|

|

You can choose between Lb or Kg |

| For every 1 kg of flour your yield is... |

100% |

20.00 |

Kg |

|

|

|

|

|

|

| For every 1 lb of sugar your yield is... |

100% |

18.14 |

Kg |

|

|

|

|

|

|

| For every 1 lb of shortening your yield is... |

100% |

8.16 |

Kg |

|

|

|

|

|

|

| For every 1 kg of salt your yield is... |

100% |

10.00 |

Kg |

|

|

|

|

|

|

| For every 1 litre of lemon juice your yield is... |

100% |

4.00 |

Kg |

|

|

|

|

|

|

| For every 1 kg of cinnamon your yield is... |

100% |

2.50 |

Kg |

|

|

|

|

|

|

| For every 1 gallon of apples your yield is... |

90% |

3.41 |

Kg |

|

|

|

|

|

|

| For every 1 each of cinnamon candy your yield is... |

100% |

500.00 |

each |

|

|

|

|

|

|

| For every 1 gallon of water your yield is... |

100% |

14,384.52 |

Kg |

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

- |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Recipe scaling per batch |

Units (you can change each one) |

Jeff Fidyk:

Enter the amount of each ingredient you use per a batch of your product.

There are multiple alternative measurement types you can choose from in column B.

Amount per batch |

Jeff Fidyk:

This column shows the total cost of each ingredient you are using per batch.

Total cost |

Jeff Fidyk:

This column shows each how much each ingredient in the batch costs relative to the total.

Share of total cost |

|

|

|

|

|

|

| flour |

|

210.00 |

$100.23 |

20.8% |

|

|

|

|

|

|

| sugar |

105.00 |

$57.87 |

12.0% |

|

|

|

|

|

|

| shortening |

45.00 |

$145.30 |

30.2% |

|

|

|

|

|

|

| salt |

2.10 |

$0.57 |

0.1% |

|

|

|

|

|

|

| lemon juice |

2.20 |

$10.45 |

2.2% |

|

|

|

|

|

|

| cinnamon |

1.50 |

$2.18 |

0.5% |

|

|

|

|

|

|

| apples |

59.00 |

$157.44 |

32.7% |

|

|

|

|

|

|

| cinnamon candy |

360.00 |

$6.48 |

1.3% |

|

|

|

|

|

|

| water |

105.00 |

$0.38 |

0.1% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

$- |

0.0% |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Total cost per batch |

$480.91 |

|

|

|

|

|

|

|

| Total weight |

601.53 |

|

|

|

|

|

|

|

| Batch cost per Kg |

$0.80 |

|

|

|

|

|

|

|

| How many individual units do you get per batch? |

Jeff Fidyk:

Enter the total count of individual units you yield from each batch.

So if you are making cookies and get 10 dozen or 120 cookies, enter 120.

360.00 |

|

|

|

|

|

|

|

| How long does it take to make a batch from start to finish? |

|

|

140 |

minutes |

|

|

|

|

|

|

| How many individual units will you put into each package? |

|

|

Jeff Fidyk:

Enter the number of individual units you are going to put into each package.

If you are making pies and selling them by the each, you would enter 1 here. If you are making cookies and plan to sell them by the dozen, enter 12 here.

1.00 |

|

|

|

|

|

|

|

| Number of packages you will get per batch is |

|

|

360.00 |

|

|

|

|

|

|

|

| What is the finished product you are making? |

apple pie |

|

|

|

|

|

|

|

| Here is your cost per package before wastage |

$1.34 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Wate per batch |

Amount per batch |

Total cost |

|

|

|

|

|

|

|

| Raw materials waste (Kg) per batch |

Jeff Fidyk:

Once you've mixed the ingredients and if you have some left over that cannot be carried forward to the next batch, enter the amount here.

Only enter the amount that tends to be left over each time.

1.05 |

$0.84 |

|

|

|

|

|

|

|

| Splash over (Kg) per batch |

Jeff Fidyk:

If some mixed ingredients are lost during production and this tends to be the norm when mixing a batch, enter that amount here.

0.50 |

$0.40 |

|

|

|

|

|

|

|

| UNITS of finished product used to QC testing |

Jeff Fidyk:

You may want to check some units from each batch to ensure they were made properly. If you tend to pull some items for Quality Control testing, enter the average number of units tested here.

2 |

$2.68 |

|

|

|

|

|

|

|

| Total waste per batch |

$3.92 |

|

|

|

|

|

|

|

| Waste cost per unit |

$0.01 |

|

|

|

|

|

|

|

| Total cost per unit (A99 + A106) |

$1.35 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Note all above costs should be LANDED - include delivery charges/freight |

|

|

|

|

|

|

| Cost of goods |

|

|

|

|

|

|

| Food cost |

Cost |

Measure |

Packages /batch |

Cost /Package |

|

|

| Food ingredient cost |

$480.91 |

per batch |

360.00 |

$1.34 |

|

|

| Food wastage |

$3.92 |

per batch |

360.00 |

$0.01 |

|

|

|

|

|

|

|

|

|

| Unit packaging |

Detail |

Purchase cost/case |

Purchase units/case |

Amount used/unit |

cost /package |

|

| Unit packaging part 1 |

pie tin |

$28.00 |

250 |

1 |

$0.11 |

|

| Unit packaging part 2 |

box |

$21.00 |

300 |

1 |

$0.07 |

|

| Unit packaging part 3 |

overwrap |

$18.00 |

2500 |

1.25 |

$0.01 |

|

| Unit packaging part 4 |

Label |

$8.00 |

1000 |

1 |

$0.01 |

|

| Unit packaging part 5 |

|

|

|

|

$0.00 |

|

|

|

|

|

|

|

|

| Case packaging |

Detail |

Purchase cost/case |

Purchase units/case |

Amount used/case |

How many packages of apple pie /case? |

Cost /package |

| Master package (carton or base) |

Carton |

$40.00 |

20 |

1 |

12 |

$0.17 |

| Master label |

Label |

$5.00 |

25 |

1 |

12 |

$0.02 |

|

|

|

|

|

|

|

| Case closure |

|

Purchase cost/case |

Purchase units/case |

Amount used/case |

Cost /package |

|

| Master closure (tape or overwrap) |

Tape |

$3.50 |

1000 |

3 |

$0.01 |

|

|

|

|

|

|

|

|

| Note all above costs should be LANDED - include delivery charges/freight |

|

|

|

|

|

|

|

|

|

| Labour |

Rate/hour |

Hours /batch |

Total |

Labour /package |

18% is added to each of the rates/hour to allow for extra cost of hiring labour |

| Direct labour - food production - #1 |

$28.00 |

1.5 |

49.56 |

$0.14 |

| Direct labour - food production - #2 |

$0.00 |

0 |

- |

$0.00 |

|

|

|

|

|

| Direct labour - unit packaging - #1 |

$12.00 |

1.5 |

21.24 |

$0.06 |

| Direct labour - unit packaging - #2 |

$0.00 |

0 |

- |

$0.00 |

|

|

|

|

|

| Direct labour - master packaging - #1 |

$12.00 |

0.75 |

10.62 |

$0.03 |

| Direct labour - master packaging - #2 |

$0.00 |

0 |

- |

$0.00 |

|

|

|

|

|

| Total cost of goods (per unit) |

$1.97 |

|

|

|

|

|

|

|

|

|

| Cost summary & analysis |

Cost |

Ratio |

Summary ratios |

|

|

|

| Total food cost |

$1.35 |

68.5% |

68.5% |

|

|

|

| Total packaging cost |

$0.39 |

20.0% |

20.0% |

|

|

|

| Direct labour - food production |

$0.14 |

7.0% |

|

|

|

|

| Direct labour - unit packaging |

$0.06 |

3.0% |

|

|

|

|

| Direct labour - master packaging |

$0.03 |

1.5% |

11.5% |

|

|

|

| TOTAL |

$1.97 |

100.0% |

100.0% |

|

|

|